是什么让企业在动荡时代站稳脚跟?墨守成规总归不是妙计。

来自 | E&P

编译 | 二丫 影子

EIA分析,7月页岩油的产量为547.5万桶/日,首次超过2015年3月的峰值546万桶/日,8月页岩油产量将会再涨11.3万桶/日,创造历史新高558.5万桶/日。但随着美国夏季开车出行高峰期的到来,原油需求和汽油需求将大幅增长,市场也许会逐渐回暖。

采用的页岩油气开采工艺和技术后,石油公司便可以低成本地从页岩地层开采石油了。Rystad Energy高级分析师Bielenis Villaneuva-Triana在年初的一篇报道中称,页岩油的开采成本平均降低了约47%。在美国五个主要的页岩油产区,使用水平井钻井技术开采石油的成本已经降到了不足40美元/桶,北达科他州的Bakken地层的开采成本最低,为31美元/桶。而根据Suncor公司第三季度业绩数据,其在加拿大开采油砂的现金成本为27.65美元/桶。

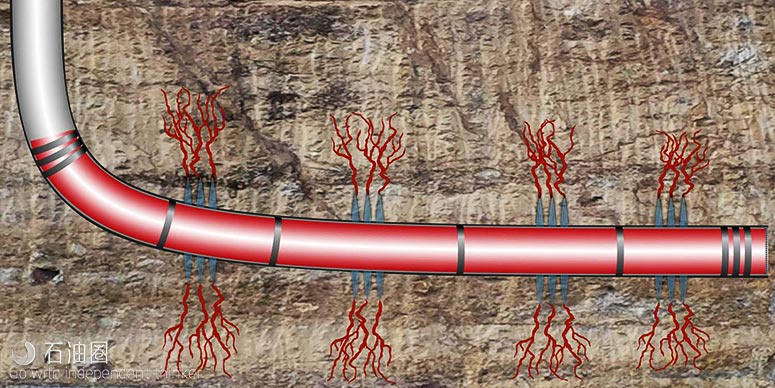

转向系统提高压裂作业一致性

新型转向系统提高压裂作业一致性

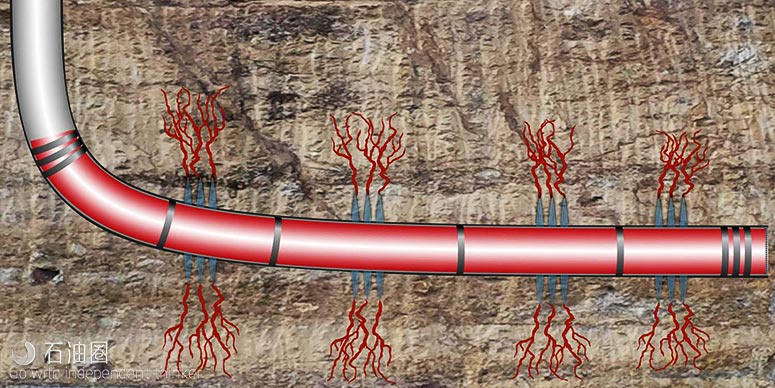

T公司近日推出了新型压裂转向系统—S,该公司表示,S是目前业内最经济、适用性最强的压裂转向系统。S Perf PODs是一种井间压裂转向系统,可封堵圆形及不规则形状孔道,是后期完井作业及重复压裂作业解决方案。与常规技术不同,在射孔内部完成对孔道的封堵,不会破坏油藏或压裂裂缝。S转向技术能够显著降低桥塞用量,同时保持不同压裂段或产层之间间隔更小。S只需通过电缆/钢丝操作,避免了预装堵头引起的相关风险,包括泵入时间、完井成本、下入及后期磨铣作业等都会得到优化。在桥塞间使用S能够最大化产层采收率,完成所有产的增产作业,不会有任何甜点遗漏。S在可降解封堵及磨铣类封堵压裂作业中都可应用,决定其使用的关键参数是井底温度及压力。Perf PODs在地面即可完成安装,在压裂过程中发挥关键的导向作用,确保后期压裂隔离、破堵等作业顺利完成。

复合压裂桥塞有效改善PNP作业速率与可靠性

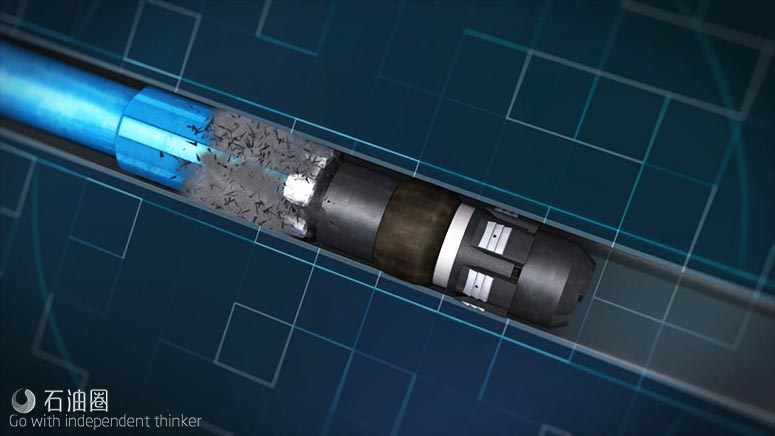

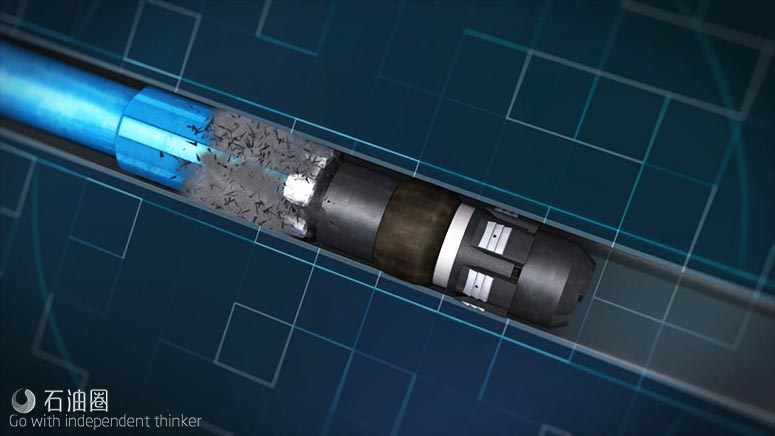

深受非常规作业人员青睐的PNP完井方法是一种密集型工艺。然而使用复合桥塞作业总是要花上几天的时间,并且桥塞还有可能会堵塞井眼,或是发生提前坐封等问题,结果往往会导致额外的修井作业。

复合压裂桥塞T在PNP作业中将作业效率和可靠性提升到了一个新的高度,流线型设计使其比业内的其他竞争对手强大的多。该桥塞的一大亮点是,它具有单组卡瓦和传统的双组卡瓦两种配置,可减少40%的材料使用量,与标准桥塞设计相比,长度更短。在不牺牲工具强度和可靠性的前提下,该桥塞的磨铣时间较常规桥塞相比,平均减少50%。该桥塞还含有一个超耐用的滑环,降低粘附和提前坐封的风险。

俄克拉哈马州的一口井垂深4572m(15000ft),水平段3048m(10000ft),使用T桥塞后,平均速度达到122m/min(400ft/min),这几乎是之前所用的标准桥塞的两倍。在整个作业过程中,没有发生任何粘附和提前坐封的情况,实现零NPT。在此次作业中,配合使用该公司的V钻头,钻井时间共节约80%,所有桥塞实现一趟钻,也实现了更有效的井筒清洁。

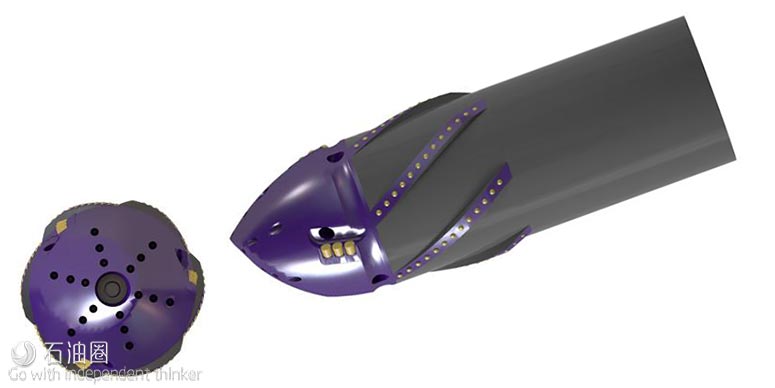

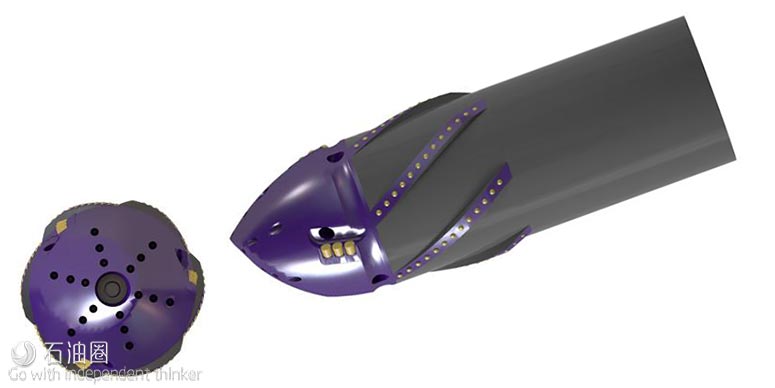

新型划眼引鞋有利于将套管下入设计井深

D公司发布了一款集成了PDC切割结构的优质划眼引鞋R。该工具采用特殊设计, wellbore-seeking偏心引鞋头可应对比较麻烦的地层,具有防腐效果的左叶可最大限度地减小扭矩,另外还配有用于钻出的PDC可铣削引鞋头以及可配合多种套管尺寸使用的碳化物切削结构。

当井壁质量关系到套管是否能够下入到设计井深时,便是R发挥作用之日。对于有效的套管作业,页岩往往会对其构成很多威胁。它们易于膨胀、脱落和变形,这些都会使套管被卡住或是磨损传统套管鞋。为了解决这些问题,D公司提高了引鞋头的合金化合物性能,改善工具的耐磨性。沿着引鞋头,R还具有三排PDC切削齿,实现真正意义上的切削结构。

可膨胀尾管助力重复压裂

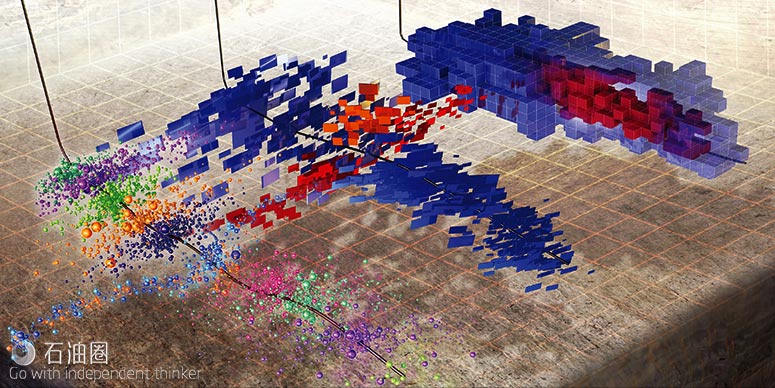

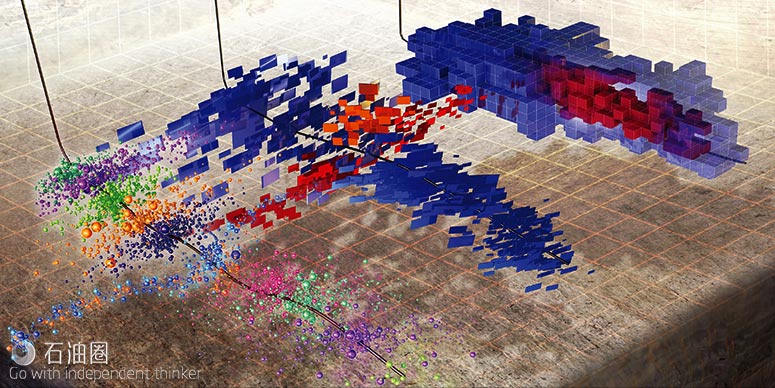

运营商们正在试图改进压裂设计,来提高成熟油田和大量低渗页岩井的产量和估算最终储量。目前,已经有多重机械和化学重复压裂技术被应用,但效果却差强人意。例如,使用微粒进行密封作业,其无生产能力的射孔往往不可预测、不可靠。化学导引剂缺乏内部压力完整性,往往倾向于遵循最小阻力的路径。基于上述技术缺陷, E公司开始研发可膨胀重复压裂尾管—E尾管。

全新的尾管可实现老炮眼的区域隔离,保证内部压力完整性,让压裂作业变得更具可预测性。这一解决方案让投资回报变得更快,生产寿命也得到了延长。与传统的重新完井相比,使用E尾管可以增加47%的流动面积。是个可膨胀密封件确保了老炮眼的准确隔离,作业人员能够有效地利用以往经验完成最佳的重复压裂作业。

重复压裂过程中的表面压力与初次压裂的相同,表明E尾管可以用于压裂新储层。

融合回收、管道部署和套管切割于一体

G公司的H系列工具在一口井的整个工程中提供着多种功能。这一工具系统可以作为套管或管道部署的高速扩眼解决方案进行配置和运行,或者作为带集成钢丝刷的套管清刮器,该系统还可用作清理井筒的喷射工具。其旋转速度超过1500rpm,可形成更好的泥浆状态,并且最小化古井期间的水泥/泥浆污染,是套管和尾管固井的理想选择。

H工具旨在结合各种功能,替代标准的固井和导向引鞋,扩展其他的应用可能性。当泵打开时,循环流体流过H工具的中央花键,然后通过一组叶轮强制通过内套筒中的凹槽。整个过程随后产生高转速、低压降和低扭矩,使其成为水平井固井的天然最佳拍档。

H工具包含一个低扭矩的高速套管/固井/划眼引鞋,可提供足够的扭矩;还具有配备中心喷射器的多级喷嘴结构,确保流体的径向沉积,限制向下喷射,减少固井时流体之间的污染。另外,中心喷嘴可以被隔离开,从而将流体的流动方向集中到井壁上,以发挥其他用途。

下期关键词:压裂工具,增产系统

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

柠檬:186-2292-2332;weiyameng@fonchan.com

二丫:131-3255-0596;zhanglingyu@fonchan.com

For English, Please click here (展开/收缩)

DIVERTER SYSTEM ALLOWS OPERATORS TO MAINTAIN MORE CONSISTENT STIMULATION VOLUME

T’ S diverter system is the most economical and adaptable diverter on the market, according to the company. S Perf PODs are an interwellbore diverter designed to seal both circular and irregular-shaped holes, providing a solution for new completions and refracturing operations. S Perf PODs seal inside the perforation, eliminating any formation damage or residual fracture obstructions. S diverting technology allows operators to reduce the number of bridge plugs within a wellbore while maintaining the advantages of closer stage spacing and additional clusters. The risk of a preset plug can be drastically reduced along with pump down time, completion cost and resources associated with the corresponding wireline runs and subsequent mill out work. Applying between bridge plugs allows the operator to achieve maximum cluster efficiency while stimulating the entire stage without leaving orphan clusters behind. S Perf PODs are available in both degradable and millable materials optimized for each wellbore based on bottomhole temperature and pressure ratings. Deployed from surface, Perf PODs are launched during the fracture to divert flow, allowing subsequent breakdown and perforation isolation.

COMPOSITE FRACTURE PLUG IMPROVES PNP SPEED, RELIABILITY

Plug-and-perf(PNP) completions favored among unconventional operators are process-intensive. Composite plug drillouts can take days, and the plugs can become stuck in the wellbore or set prematurely, resulting in unplanned interventions. T composite fracture plugs deliver a new level of efficiency and reliability in PNP operations using a streamlined design that is also more robust than competitive offerings. The plug, which features a single set of slips vs. the conventional two sets, contains 40% less material and is shorter in length compared to standard plug designs. The plug cuts millout times by an average of 50% without sacrificing strength or reliability. The plug also incorporates an ultradurable slip ring and contains no ceramic or carbide buttons to reduce the risk of sticking and plug presets. An Oklahoma operator recently ran 33 T composite plugs in a 4,572-m (15,000-ft) well with a 3,048-m (10,000-ft) lateral section at an average rate of 122 m/min (400 ft/min)—almost double the average run-in speed for standard plugs in previous jobs. No sticking or presets resulted in zero plug-related nonproductive time during well completion. Drill-out time was cut by 80%, from 15 to 3 minutes per plug, and all plugs were drilled out in a single trip using a V drillbit. The smaller overall volume of cuttings enabled easier, more effective wellbore cleanup.

NEW REAMER SHOE HELPS RUN CASING TO TOTAL DEPTH

D has released R, an aggressive reamer shoe with an integrated polycrystalline diamond composite (PDC) cutting structure. Building off the Pen-O-Trator design, R features a wellbore-seeking eccentric guide nose to negotiate troublesome formations, anti-aggressive left-hand blades to minimize torque, a PDC millable nose for drillout and a casing-friendly tungsten carbide cutting structure on the body. R has been designed specifically for use in applications where hole wall quality is a concern for getting casing run to total depth. Shale formations pose several challenges for effective casing running because they are prone to swelling, sloughing, ledging and formation shifts—all of which leave casing stuck or wear out traditional casing shoes. To combat these problems, D has enhanced the alloy compound of the nose, providing improved wear and erosion resistance. The R also features three rows of PDC cutters along the nose for a true cutting structure to remove formation as needed while casing is run to bottom.

EXPANDABLE LINERS LEAD TO PRECISE REFRACTURING APPLICATIONS

Operators are taking advantage of improved fracturing designs to increase production and EURs of mature and largely impermeable shale wells. Various mechanical and chemical refracturing techniques have been employed with mixed results. For example, sealing off older unproductive perforations with particulates is unpredictable, unreliable and requires multiple attempts. Even then, sustained integrity remains a question. Chemical diverting agents lack internal pressure integrity and tend to follow the path of least resistance. These limitations led E to develop the expandable refracturing liner. The liner provides a new wellbore with zonal isolation of existing perforations and internal pressure integrity that enables greater predictability of planned fracture stages. This method translates into a faster payback on investment and extended production life. The E Liner increased flow area by 47% compared to the conventional recompletion option. Ten expandable seals placed along the liner ensured accurate isolation of old perforations, enabling the operator to effectively apply lessons learned for an optimal refracturing program with a new wellbore. Surface pressures during the refracture were identical to those during the initial fracture, indicating that the E Liner enabled the operator to fracture into a new, untouched reservoir.

TOOL’S USES INCLUDE REAMING, TUBULAR DEPLOYMENT AND CASE SCRAPING

G’s H family of tools provides a variety of functions in the life of a well. This system can be configured and run as a high-speed reaming solution for casing or tubular deployment or used as a casing scraper with integrated wire brush. The system also can be used as a jetting tool for wellbore cleanup operations. With rotary speeds in excess of 1,500 rpm, the H is an ideal candidate for casing and liner cementing operations since the fluid pattern created at the shoe ensures better mud condition is achieved and should minimize cement/mud contamination during cementing. The H is designed to replace standard cementing and guide shoes by combining their respective features, extending their possible application. When the pumps are on, the circulated fluid is channeled through the central spline of the H tool and then forced through grooves in the inner sleeve via a set of impellers. This process results in high rotational speeds, low pressure drop and low torque, making this a natural fit for high-angle horizontal well cementing operations. The H has a low-torque high-speed casing/ cementing/reamer shoe that provides sufficient torque to get through slight obstructions in the borehole such as cuttings beds, debris and slight tight hole conditions. The tool also has a multijet nozzle configuration with a center jet that ensures radial deposition of fluids as well as a limited downward jet, which reduces contamination between fluids when displacing cementing. The center jets can be blanked off to concentrate fluid direction toward the borehole walls. This is relevant for cuttings beds agitation and shale breakouts.

未经允许,不得转载本站任何文章:

石油圈

石油圈