OriginOil Inc. developer of Electro Water Separation? (EWS), the high-speed, primarily chemical-free process to clean up large quantities of water, announced today that independent third-party testing by Zalco Laboratories confirmed that OriginOil’s PRIME product for oil & gas operations successfully reduced contaminants in produced water to the level required for reuse for cyclic steam stimulation (CSS) — a type of enhanced oil recovery.

By 2030, water demand will outstrip supply worldwide*. This growing emergency is driving the need for more efficient water reclamation.

But a great deal of water is so loaded with oil products, suspended solids, and dissolved contaminants, that it remains difficult and expensive to fully reclaim it. Often, hazardous chemicals such as chlorine are part of the solution, but create their own special problems.

Electro Water Separation? (EWS) is a highly scalable, continuous process that uses electricity in small, programmed doses to gather up oils and suspended solids, and through Advanced Oxidation or AOx, to remove fine, micron-sized suspended solids, and dissolved contaminants such as ammonia.

“OriginOil’s field operations in the Monterey Basin have shown our strongest performance yet. The produced water was challenging to treat due to the low API oil, which is totally different than the water from the natural gas fields of Colorado and the light oil reservoirs of West Texas”

Paul Conrad, President of Total Western Inc., a Bakersfield-based energy service company, stated, “We have been impressed by its performance in the form of final water quality and the separation of the oil from the produced water. In addition, we have found that with its smart control system, the operation is almost hands-free.”

“Zalco Laboratories has more than 30 years’ experience delivering water and liquid analysis for the oil industry,” said Juan Magana, Project Manager of Zalco Laboratories. “We are pleased to provide accurate and timely water quality analysis to assist OriginOil in its validation of its PRIME system.”

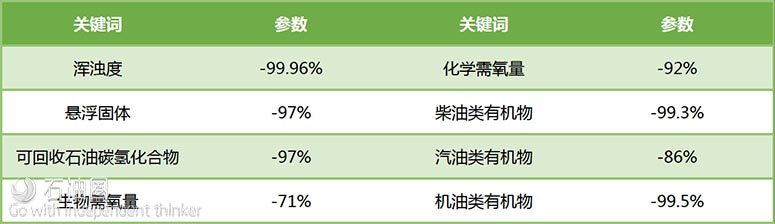

Zalco Laboratory confirmed PRIME’s ability to achieve the following results:

1.Turbidity reduced by 99.96 per cent;

2.Total suspended solids reduced by 97 per cent;

3.Total recoverable petroleum hydrocarbons reduced by 97 per cent;

4.Biological oxygen demand reduced by 71 per cent;

5.Chemical oxygen demand reduced by 92 per cent;

6.Diesel range organics reduced by 99.3 per cent;

7.Gasoline range organics reduced by 86 per cent;

8.Motor oil range organics reduced by 99.5 per cent.

“OriginOil’s field operations in the Monterey Basin have shown our strongest performance yet. The produced water was challenging to treat due to the low API oil, which is totally different than the water from the natural gas fields of Colorado and the light oil reservoirs of West Texas,” said Lee Portillo, OriginOil’s VP of Engineering for the Oil & Gas Division. “We have learned a lot from the multiple test sites and are now utilizing this long-term operating experience to maximize the performance of our breakthrough PRIME solution.”

Bill Charneski, president of OriginOil’s Oil & Gas Division, added, “It has been eye-opening to see the response to our solution from the E&P operators in the Bakersfield area. We’ve found that operators are aware of both the scarcity of fresh water, and need to treat produced water, rather than dispose of it. Many are actively looking for solutions to treat produced water to be reused for irrigation in California’s drought-stricken Central Valley. It goes beyond the economics – it’s about having access to fresh water and giving back to local farmers.”

Electro Coagulation (EC): the process begins.

Waste water enters the system through continuous tube-shaped inline reactors. These create extended residence time while keeping the process continuous. In these tubes, metal ions are transferred to trigger particle aggregation. The process can be designed to use degrading anodes, or to operate without any anode degradation whatsoever, as the application requires.

This stage coagulates the suspended solids, oil and grease, and non-soluble organics so they can be removed in the next stage, Electro-Flotation.

The generation of Reactive Oxygen Species (ROS) begins here. ROS are ozone, hydrogen peroxide and hydroxyls. These can degrade virtually any contaminant found in water. Being solely composed of oxygen and hydrogen, they also introduce no additional hazardous element in the water, a major benefit for operators wanting to avoid managing hazardous materials.

Electro-Flotation (EF): separating the suspended solids.

During the Electro-Flotation stage, an array of reactors at the bottom of the flotation tank produces gases electrochemically, resulting in a finely bubbled “cloud”.

This stage separates the suspended coagulated material and completes the process of breaking the oil emulsion. It creates a “mat” of aggregated waste which it pushes to the surface for mechanical removal.

Advanced Oxidation (AOx): disinfection and decontamination.

The EWS:AOx research team developed AOx as an evolution of known Advanced Oxidation processes.

The AOX reactor takes water that is largely clear of suspended solids and oils. In the earlier stages, it has begun to acquire disinfecting and decontaminating oxidants: Reactive Oxygen Species or ROS.

In the AOx reactor, reaction with the anode surface inside the reactor causes the on-site generation of a large amount of ROS.

At this stage, fine, micron-sized suspended solids, and dissolved contaminants, will precipitate and sink to the bottom of the AOx tank for removal.

Depending on the application requirements, AOx can be implemented either in tube-shaped inline Advanced Oxidation Reactors or in an Advanced Oxidation tank, both featuring OriginClear’s patented reactor design.

AOx can also generate other compounds through electro-chemistry, such as chlorine, to address specific contaminants such as ammonia, phosphorus or hydrogen sulfide (H2S).

Effective in water-intensive industries.

Because of its impressive feature set, EWS:AOx is valuable in water-intensive industries such as oil & gas, agriculture including algae production, and industrial wastewater management.

EWS:AOx is currently deployed in various industry applications ranging from cleaning up produced water or “frack” flowback water in oil and gas well operations, to harvesting algae for beneficial products such as fish feed.

Continuously fast and extremely thorough cleaning.

This multi-stage process is an energy-efficient, continuous system that advanced testing has shown can achieve up to a 99.9% removal of dispersed oil and a 99.5% removal of suspended solids and organics*, as well as specific contaminants such as ammonia, phosphorus and hydrogen sulfide.

Proprietary electrode arrays.

A specific feature of EWS:AOx is the proprietary design of the electrodes where Electro-Coagulation, Electro-Flotation and Electro-Oxidation work in sequence.

Their design provides the most efficient contact and mixing method for the processed fluids and the reactive species, and their specificity is a combination of anode/cathode shape, size, position, as well as selection of the electrode materials.

Solid-state process control.

The heart of EWS:AOx is a proprietary solid-state process control unit (PCU) that controls the entire process, and customizes the power requirements of each application. We are continuously evolving new features to reduce operator intervention and standardize the operating parameters.

石油圈

石油圈