在多重因素推动下,隔水套管支撑平台正逐步成为浅海油田开发的新伙伴。

来自 | E&P

编译 | 张良爽

隔水套管支撑平台(CSPs)适用于西非、东南亚和地中海等地区的平静浅海水域,在争夺第一桶油的竞争中,为了高效地制造安装钻井平台,CSPs得到了快速发展。与浅海开发项目中的传统导管架式平台和水下采油树相比,CSPs的交货期更短,人工干预和平台成本更低,项目管理更简便;从财务和技术方面来说,CSPs的主要特点就是能使用同一个自升式钻井平台来安装并进行钻井。

CSPs能够分开在不同场地,以较小规模建造安装,在对模块化井口平台的需求增长拉动下,CSPs的部署也在不断增加。CSPs的安装很灵活,零部件可用供给船运输,并用标准悬臂自升式钻井平台安装固定,不需要额外的重型吊装船或使用小型浮式起重机、起重机船或人字吊臂起重机。定制化设计不需要潜水员或遥控潜水器,也无需任何热工作业,减轻了设施的内在风险和调度障碍,降低了成本。此外,如果项目出于经济或政治因素考虑需要在一定程度上当地化,CSPs或许也能满足这一需求。

最简设施CSPs

在浅海开发项目中,能用钻机安装的CSPs,其优势往往超过传统平台和水下采油树。Aquaterra Energy公司在近十年的时间里,一直在使用自有的名为Sea Swift的最简设施CSP。利用该公司的复杂结构工程建模软件和分析,Sea Swift能够根据特定地点的海洋气象和岩土

工程技术数据,确定其系统强度、稳定性和疲劳寿命。Sea Swift结合了水下开发中的平台和钻机驱动优势,减少了资本投入以及安装和人工干预成本。

Sea Swift已经安装于多个浅海区域

Sea Swift 已在浅海区的多个地点安装,包括西非三处、埃及一处以及远东一处。 最近,Aquaterra Energy宣布,他们已为PICO公司(Amal油田的首席承包商)设计、制造并在Amal油田安装了一个新的Sea Swift平台,另一个平台正准备运往特立尼达和多巴哥岛海域。

迄今为止,在已部署的Sea Swift平台中,最大水深为65米(213英尺),位于马来西亚半岛的海上。在上部完全承重超过400吨的CSP平台中,Sea Swift也是已知的水深最大的平台。经过尝试和测验的设计概念中,Sea Swift的最大水深可达80米(262英尺)。Aquaterra

公司正对其概念进行工程评估,希望能将最大水深延伸至90米(295英尺)甚至100米(328英尺),并同时考虑多种安装方式。

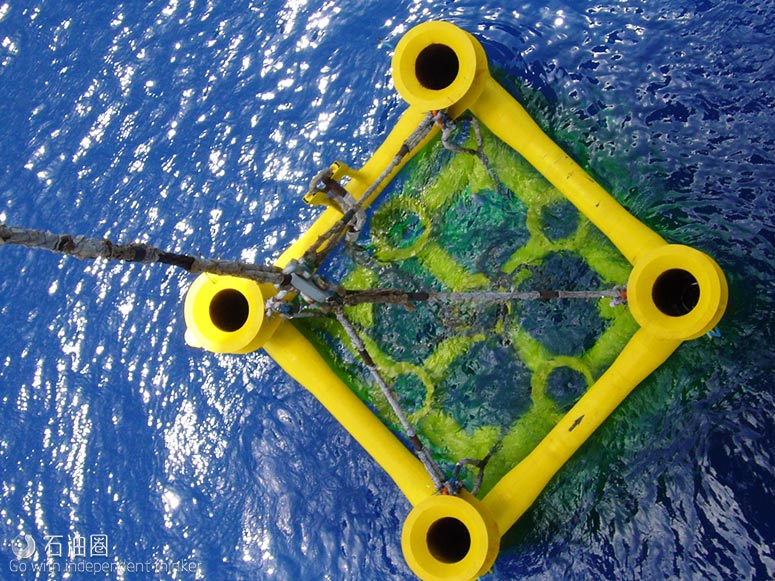

在马来西亚,Sea Swift通过一个自升式平台实现安装

最近,一座Sea Swift平台在埃及海上的Amal-C油田完成了安装,其水深23米(75英尺),上部结构重达385吨,该平台包含一个直升机坪和应急生活区,并配置了可钻6口井的设备。从最初的一个概念,到最终作业完工,该平台仅仅用了18个月;对比传统平台,Sea Swift平台成本更低,交付周期大大缩短,它能使受限于现有井槽的平台迅速增加产量。在其他应用中,它能够用干采油树进行钻完井,并且能在其他主要工艺平台抵达前进行安装。

另一座将用于特立尼达和多巴哥岛海上油田的Sea Swift平台正在建造当中。它的水下安装深度为27米(88.5英尺),能够钻4口井,包含一个就地发电、管汇和控制系统。该项目的设计阶段预计需要6个月时间,将会与制造阶段进度重合,以满足严格的交期要求。

2014年,一座Sea Swift平台安装在贝宁共和国海域的的Sèmè油田,水深26米(85英尺)。该轻型平台在突尼斯制造,通过自升式钻井平台的钻机安装,由SAPETRO公司进行调试运行,连接了五口油井至陆上油品处理设施。通常Sea Swift平台的上部结构都是通过自升式平台进行安装并完成钻井操作,但Sèmè油田是用铺管船安装的上部结构,这就消除了由自升式平台起重和拖行最大重量规格带来的限制。

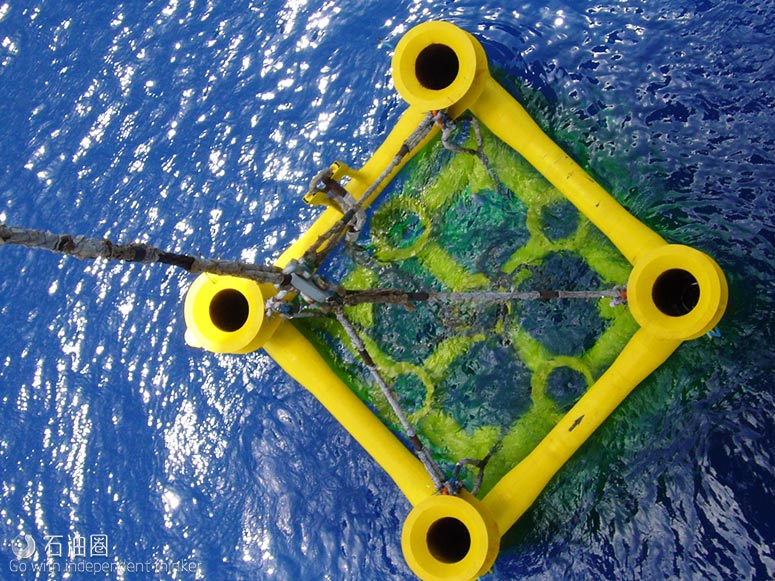

2014年,一座Sea Swift平台安装在贝宁共和国海域的的Sèmè油田

这艘铺管船包括一个200吨的一体式甲板、立管导向、船码头和一个121吨的水下导管架结构。设备通过集成光纤通信和电缆由陆上设施进行控制。独立的Sea Swift平台与4根直径30英尺的隔水套管通过水下结构连接在一起,为上部结构提供支撑,还能够容纳钻井套管。

在贝宁的最大城市Cotonou的陆上设施中,通过光纤通信和电缆,作业者可控制海上生产。

早期的分析与评估

隔水套管通过轴向压力和抗弯阻力支撑起上部结构以及套管、井口和采油树,其总长度取决于平台的水深、上部结构高度以及基础深度。水下支撑结构用来提高隔水套管的稳定性,以减少疲劳延长设计寿命。在设计较深的水深时,需要考虑上部结构的建议重量,它在限制设施数量和安装技术方面有重要影响。

Sea Swift 平台本质上是利用了油气井外围的隔水套管作为主要的结构支撑,承受平台上部结构及相关设备的重量。每个平台的子结构都单独设计,以适应不同参数条件,如水深、土壤结构和海洋条件等,特别是波频。这些设计需要在任何水深情况下,最大限度提高疲劳寿命和整个结构的稳固性,在正常情况下寿命至少25年。由于潜在的复杂环境条件,抗疲劳成为CSPs以及其他海上动态敏感型结构设计改进的主要驱动力。

Aquaterra公司通过其出色的结构工程建模软件和分析技术,展示了CSPs在海上应用时的海上可施工性、现场的强度和稳定性、动态响应和抗疲劳性能,以及基于土壤、海洋气象数据和设备载重的抗震设计特点。捕捉并理解这种动态行为特点,能够设计出符合应用环境载

荷的结构。对阴极保护和焊缝改进等各种疲劳设计因素的检查,将实现疲劳寿命最大化。此外还要对很多地区常见的地震活动进行评估,以决定地震荷载,并判断是否需要采取强化措施,使基础更加牢固安全。

Sea Swift在埃及安装于23m水深处,从设计到安装完成共经历18个月

推动设计发展

随着钢材价格大幅下跌,传统导管架平台与Sea Swift平台之间的直接成本差额正在逐渐缩小。但当使用更小更灵活的制造场地,并使用自升式平台进行安装,简化项目管理和降低风险时,Sea Swift在节约总体成本上的优势就凸显出来了。一方面,CSP的适用水深不断增加;另一方面,油气勘探成本严重受限。在二者的共同推动下,CSP正迅速成为浅海边际油田实现快速高效生产的经济有效选择。

您也有让人挠头的难题需要解决,或是优质技术想要找应用市场吗?如果有的话,欢迎联系小编微信或邮箱,也许能找到一剂良药。

二丫:131-3255-0596;zhanglingyu@fonchan.com

For English, Please click here (展开/收缩)

Suitable for use in benign, shallow-water locations such as West Africa, Southeast Asia and the Mediterranean, conductor-supported platforms (CSPs) are seeing growing demand because of a need for speedy, efficient fabrication and installation in the race for first oil. Compared to conventional jacketed piled platforms or subsea trees for shallow-water development projects, CSPs boast shorter delivery times, reduced intervention and platform costs, and simplified project management. The CSP’s main financial and technical attributes are borne from the ability to combine the use of the same jackup rig to install the CSP as well as drill at site.

The deployment of CSPs is increasing because of growing demand for modularized wellhead platforms, which can be built and installed in smaller discrete packages across several fabrication yards. The CSP allows flexibility of installation, allowing the parts to be shipped by a supply vessel and fixed in place by a standard cantilever jackup rig without additional heavy-lift installation vessels or by the use of small crane barges, lift boats or shear leg cranes—whatever is available in the region. The bespoke design also negates the need for diver or ROV involvement and any hot work, which mitigates inherent risk and scheduling barriers while cutting incremental costs. In addition, the CSP can potentially increase local content if this is an economic or political driver for the project.

Minimum-facility CSPs

The benefits of rig-installable CSPs often outweigh those of traditional platforms and subsea trees for shallow-water development projects. Aquaterra Energy has been delivering its own minimum-facility CSP option, Sea Swift, for nearly a decade. The use of the company’s own complex structural engineering modeling software and analysis is used to determine system strength, stability and design fatigue life of the Sea Swift with location-specific metocean and geotechnical data. Sea Swift combines the advantages of a platform with the rig-run benefit of a subsea development to achieve lower capital and installation/intervention costs.

Sea Swift has been installed across several shallow-water locations, including three in West Africa, one in Egypt and one in the Far East. Recently, Aquaterra Energy announced it had designed, fabricated and installed a new Sea Swift platform for PICO Petroleum Integrated Services, the lead contractor for Amal Petroleum Co.’s Amal Field, in the Gulf of Suez offshore Egypt. Another is underway offshore Trinidad and Tobago.

Its deepest deployment to date is at 65 m (213 ft) water depth using two subsea structures offshore Peninsular Malaysia. Sea Swift is also the largest known CSP in terms of topside weight at more than 400 tonnes fully laden. As a tried and tested concept, the maximum water depth is currently about 80 m (262 ft), with conceptual engineering assessments underway by Aquaterra to increase this capability beyond 90 m (295 ft) and even 100 m (328 ft). This investigation also will consider multiple installation options.

Sea Swift was recently installed at 23 m (75 ft) in the Amal-C Field offshore Egypt and includes a 385-tonne topside featuring a helideck and emergency accommodation with provision for six wells. The design provides a lower cost option that can be delivered significantly faster than traditional platforms—from concept to completion in only 18 months. It also can rapidly increase production from platforms constrained by existing slots and, in other applications, allows wells to be drilled, completed with dry trees and installed before the arrival of the main processing platform. The Egypt project also supported jobs in the local area at Alexandria and Zeit Bay yards.

Sea Swift construction also is underway for a field offshore Trinidad and Tobago. It will be installed at 27 m (88.5 ft) water depth; will accommodate up to four wells; and will include local power generation, manifolds and a control system. The design project, which is anticipated to last up to six months, will overlap with the fabrication to meet the tight delivery timetable.

In 2014 a Sea Swift platform was installed in the Sèmè Field in 26 m (85 ft) water depth offshore the Republic of Benin. Commissioned by South Atlantic Petroleum Benin S.A. (SAPETRO), the lightweight platform was fabricated in Tunisia and installed by a jackup drilling rig, negating the need for a heavy-lift vessel. It connects five wells to an onshore processing facility. Although a Sea Swift topside would normally be installed by the jackup completing the drilling operations, an available pipelay vessel was used for the Sèmè Field topside installation. This removed the lift weight constraint caused by the jackup lift and skidding capacity required for the installation.

The vessel consists of a 200-tonne integrated deck topsides, riser guides, boat landing and a 121-tonne subsea jacket structure. Equipment is controlled from the onshore facility via an integrated fiber-optic communication and power cable. The freestanding Sea Swift structure uses four 30-in. well conductors tied together by the subsea structure. This provides structural support to the topsides while also housing the well casings. Production is controlled from an onshore facility at Cotonou, Benin’s largest city, via an integrated fiber-optic communication and power cable.

Early analysis, assessment

Since the conductors provide structural support to the topsides through axial compression and bending resistance as well as supporting the well casing, wellhead and surface tree, the total conductor length is defined by the water depth at the platform location, topsides elevation and foundation setting depth. Subsea support structures are used to provide rigidity to the conductors and extend design life through the reduction of fatigue. The weight of the proposed topside also needs to be considered when designing for deeper depths as this will play a considerable part in limiting the facilities available and installation techniques.

Sea Swift essentially uses the well’s environmental conductors as primary structural members to support the weight of the platform’s topsides and associated equipment. Each individual platform substructure is a one-off design to suit varying parameters such as water depth; soil structure; and sea conditions, in particular wave frequency. These design considerations must be taken into account at any depth to maximize fatigue life and steadfastness of the entire structure, which can normally be left in situ for up to 25 years. Due to potentially complex environmental conditions, fatigue is one of the main design drivers for a CSP, as with all dynamically sensitive offshore structures.

Aquaterra’s in-house structural engineering modeling software and analysis expertise is used to demonstrate an acceptable structural performance for the CSP in terms of offshore constructability; in-place strength and stability; dynamic response; fatigue endurance; and seismic design based on the soils, metocean data and equipment loads. This dynamic behavior must be captured and understood to allow the structure to be designed and comply with the environmental loading applied. A review of fatigue design elements such as cathodic protection of conductors/piles and weld improvements will enable a maximum fatigue design life to be achieved. An assessment of seismic activity, which is common in many locations, must also be carried out to determine seismic loads and additional reinforcement options such as skirt piles to create a more robust and secure foundation.

Pushing the design envelope

As the price of fabricated steel has tumbled, so has the straight cost differential between a conventional jacket and a Sea Swift. However, the overall cost savings really come to the fore when using smaller and more agile fabrication yards and a jackup for installation, ensuring simpler project management and reduced risk. This, alongside its potential to reach deeper depths, has meant that in today’s cost-constrained climate the CSP is quickly becoming a more financially viable option for fast and effective production in marginal shallow-water developments.

未经允许,不得转载本站任何文章:

石油圈

石油圈