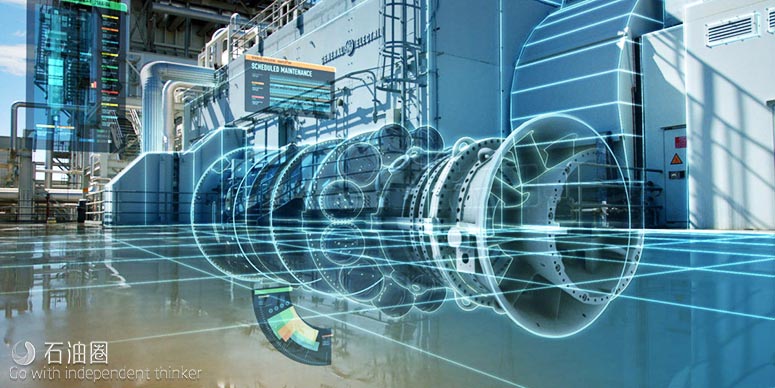

“对于油气上游行业,如何提高资本利用效率和收益能力,最小化停机时间,降低边际成本,是眼下最关键的挑战。”GE中国区CTO吴平川如是说。

来自 | E&P

编译 | 张德凯

世界级的油气大发现并没有因低迷的油价市场而“曲终人散”。

今年2月10日,伊朗国家石油公司发现了150亿桶的新原油储备,其中20亿桶是可开采的,此外还发现了1.8万亿立方米的新天然气储备,其中一半可开采。3月11日,西班牙石油公司Repsol在美国阿拉斯加州北部发现储量12亿桶的巨型油田,是美国最近30年来发现的最大油田。3月27日,英国飓风能源公司发现储量高达10亿桶大型油田,在苏格兰海岸北部设得兰群岛附近发现储量高达10亿桶的大型油田,并计划于2019年开始生产。而最近,据美国媒体报道,墨西哥湾(GOM)浅海区域被发现大量原油,预估地质储量达14~20亿桶,高于钻井前8~9亿桶的预测。

在本届世界石油大会上,IHS Markit公司副主席Daniel Yergin博士提出了当前石油行业正经历的四大变化,分别是全球市场再平衡和成本再计算、页岩气对石油工业的冲击、行业融资形势变化,以及汽车工业变革给油气市场带来的影响。而在刚刚结束的2017年石油石化信息技术峰会上,GE中国区首席技术官吴平川在发言中表示,对于油气上游行业,如何提高资本利用效率和收益能力,最小化停机时间,降低边际成本,是眼下最关键的挑战。

本期技术动态,共总结出了9项最新技术,予以分享。

ForeSite生产优化方案提高分析及网络操作能力

近日,威德福宣布,ForeSite生产优化方案正式投入商业应用。ForeSite采用了具有高级数据分析功能的物理模块,具在不同井况、油藏及地面设备的应用中都有不俗的性能。ForeSite是业内首款集成软件平台,结合了威德福的生产优化技术与互联网产品、云计算、高级分析,使得资产完全管理成为可能。ForeSite技术平台最初的设计目标是优化杆式泵人工举升系统的管理,之后逐渐推广,用于多种人工举升系统及油藏生产地面设备的管理与优化。

优化海洋环境,大规模塑料收集系统问世

Petroleum Geo-Services ASA (PGS)最近推出了一种高效、大规模海洋废塑料回收概念。该方案利用震波勘测船与生俱来的优势,使用气体压缩机将废塑料高度压缩,提高废塑料的回收能力。

据统计,全球范围内,每年有近800万吨废塑料流入海洋,相当于每分钟有一卡车的废塑料投入海水中。如果不及时采取措施,截至2030年,每年的海洋塑料垃圾量将再翻一倍,而到2050年,废塑料污染量将是现在的四倍。PGS的废塑料回收方案包含一艘地震勘探船和一艘废塑料收集船,以及一艘废塑料处理船。

地震勘探船的甲板压缩机是地震勘探的震源,其功率强大,是地震勘探船在塑料回收中的主要优势。不过与地震勘探过程相反,在废塑料回收过程中,地震勘探船的尾管要泵出气体至水下50m处,泵出气体出口在地震勘探船与支持船之间。空气被泵入水下后,依附在悬浮于水中的塑料上,将其带出水面,就像苏打水中的气泡一样。收集船尾部的处理船能够将塑料与有机物分离,之后将塑料高度压缩,做标记,当收集船满载时,将塑料收集运回陆地加工、回收。

新型集成服务优化海洋油气开发废水处理

美国某油服巨头最近推出了一种新型的集成服务。这是一款定制化、集成化的水处理方案,专门用于海洋油气开发废水处理。该服务集成了数字技术、远程监控&诊断技术、滤膜技术以及化学物质(硫化物等)移除技术。此外,它还集合了此油服公司在水处理方面的经验及专业技术。新型服务能够帮助用户提高海洋废水处理效率,优化废水处理结果,提高作业灵活性。在不同的应用中,只需在系统中输入与作业相匹配的参数,海洋油气开发商即可减少废水就地处理时间,提高废水回收效率,降低处理设备的维护成本。此外,此项集成服务还可以提高硫化物移除效率达5%,减少就地清洗时间达数小时,同时避免耗时的设备检修作业。

盐度监测系统提高流动保障

美国某公司推出了新型盐度监测系统,主要用于海上气井中伴生高盐度盐水的实时、精确监测。通过使用该系统,操作人员可精确识别流体中微小的盐度变化,新型产品监测精确度高,是目前行业内同类型产品无法达到的。运用这一系统,操作人员可及时发现流体盐度变化,做出调整,防止结垢、水合物、腐蚀等对生产造成损害。

众所周知,若不能控制地层水及其盐度,停井等问题就会发生,造成数百万美元的损失。新型盐度监测系统采用微波共振技术,提供实时的盐度定量与定性检测,适用于多种复杂情况,在高气体含量、湿气田中的应用也非常有效。

Walk to Work系统优化环境复杂地区人员转移

Ampelmann公司近日推出了新型Walk to Work系统,主要用于严寒作业地区人员穿梭。Walk to Work采用N型设计,主要用于提高严寒地区(-28℃)作业人员穿梭的安全性与效率,基于其良好的性能,工作人员更习惯称之为Iceman。Walk to Work为全封闭、隔离系统,在海面浪高3.5m时也可正常使用,采用的主动升沉补偿系统可完美化解颠簸问题。Iceman可360°旋转,在作业船上即可完成操作,灵活性高,无论平台位置如何都能快速投入使用。

目前,越来越多的海上人员穿梭作业都开始采用Walk to Work系统,在平台间、平台与作业船之间的使用大幅度提高了作业人员的安全保障,是直升机穿梭、吊篮穿梭的完美替代工具。

新型涂层膜技术有效防止腐蚀

最近,英国某公司推出了新型涂层膜技术,可通过涂刷或喷淋的方式应用于不规则表面,防止设备在严苛条件下发生腐蚀。如果将其与该公司的另外一款隔离/阻蚀剂联合使用,那么在进行设备检修或是维护过程中,该涂层膜就可以通过剥落方式与设备分离,减少了设备完全密封的工作量。该涂层可应用于多种机械设备,包括小型轴承、大型海上平台立管等,具有出色的弹性及粘结能力,在金属及涂层表明都能完美包覆,实现对设备的保护。这种涂层膜非常耐用,可阻止多种腐蚀,包括电流、裂缝腐蚀等。此外,它对于恶劣环境的适应性也非常强,在强紫外线地区应用效果也非常好。

新型系统降低暴风雨影响,提高钻机移动效率

Delmar Systems近日推出了新型RAR Plus及MOOR-Max锚泊系统。其中,RAR Plus是新一代钻机锚释放(RAR)系统,采用声学释放技术,同时附加手动释放备用系统,相比于常规工具,RAR Plus的工作载荷更大。通过内置于锚绳内的传感器,RAR Plus可以将锚绳的实时张力以直接或间接的方式显示在图形用户界面。

RAR Plus还是MOOR-Max可释锚定系统的一部分,MOOR-Max是一款主要用于海上移动式钻井设备的锚定系统,能够有效避免恶劣天气的影响,提高钻机移动效率。MOOR-Max采用Delmar公司特有的声学释锚技术,是目前业内唯一的声学锚定系统。Delmar的工程设计副总裁John Shelton说:“MOOR-Max不只能降低恶劣风暴对于钻机的影响,还能显著减少钻机移动的时间,提高工作效率。”

基于云技术实现海洋油气开发数字化

据报道,Xvision Software近日推出了业内首款完全基于云技术的管理工具—FieldAP,该工具主要用于海洋油气开发项目的可视化监测、数字化管理以及成本控制,将极大提高能源公司的工作效率。FieldAP具有在线设备管理功能,可提高作业效率,最多可使作业提前80%的时间完成,在油藏早期开发及FEED过程中的作用尤为明显。实际应用表明,在海上油气项目中,FieldAP最多可降低项目成本达70%。FieldAP将海上项目水下&平台设备及作业数据整合,以简明易懂的2D/3D可视化方式展现给操作人员。

新型系统升级数字双胞胎技术

Bureau Veritas近日推出了Veristar AIM 3D资产完整性管理系统,该技术是在Dassault Systems公司的3DEXPERIENCE技术平台上建立的。在协同环境中,新型系统可将任何船舶、海洋设备设施的数字双胞胎与智能数据处理结合。Veristar AIM 3D在海洋油气开发设备以及船队的设计、建造、使用过程中都将发挥巨大作用。此外,该系统还具有危险评估及状态检修方案制定的功能。Veristar AIM 3D系统为每个资产管理系统中的设备配置了单独的操作面板,包括船只、钻井平台、设备以及整个船队。显然,Veristar AIM 3D将大幅提高资产状态与性能的可视化,使得决策制定更加智能。

Software leverages advanced analytics and the Internet of Things

Weatherford International Plc has commercially released the ForeSite production optimization platform. The platform combines physics-based models with advanced data analytics to improve performance across wells, reservoirs and surface facilities, a press release stated. This platform is the first in a series of integrated software offerings that will combine proven Weatherford production optimization technologies with the Internet of Things, cloud computing and advanced analytics to enable complete asset management. The ForeSite platform is initially focused on improving the management of wells with rodlift systems and will later extend to all forms of lift as well as management and optimization at the reservoir and surface-facility levels.

Large-scale plastic collection concept for oceans

Petroleum Geo-Services ASA (PGS) has developed a concept for efficient large-scale collection of plastic from the oceans, a press release stated. The solution uses the inherent benefits of seismic vessels and takes advantage of their air compressors and capabilities for handling large towing configurations. Each year, eight million tons of plastic ends up in the world’s oceans—equivalent to dumping the contents of one garbage truck into the sea every minute. If no action is taken, this is expected to increase to two garbage trucks per minute by 2030 and four garbage trucks per minute by 2050. The PGS plastic collection concept consists of a seismic vessel and a support vessel towing booms, in a fan formation, which are connected to a processing unit at the end of the spread. The uniqueness of the seismic vessel is its large onboard compressors, which usually supply the seismic source. These are instead used to pump air through a ventilated hose towed at about 50 m (164 ft) water depth between the seismic ship and the support vessel. The air bubbles attach to the submerged plastic, which then rises to the sea surface, just like bubbles are attracted to a straw in a glass of sparkling water. The processing unit at the end of the collection spread separates organic materials from plastic. The latter is compressed and packaged into super-strong synthetic skins. Once full, each skin section is marked by GPS and AIS, ready to be collected and towed to a processing facility for recycling.

Integrated service offering for offshore oil and gas water treatment

GE Water & Process Technologies has released its new OnBoard service offering, a customizable, total integrated water treatment solution and service plan for offshore oil and gas producers, a press release stated. OnBoard incorporates digital technologies, remote monitoring and diagnostic software, membranes, chemicals, sulfate removal technology, and offshore field and process expertise. The service helps producers improve operations, performance and profitability at offshore water treatment facilities. By choosing the OnBoard program parameters that match their unique needs, offshore oil and gas producers and operators have the potential to decrease clean-in-place time, improve recovery rates and lower maintenance costs. The program is also designed to increase sulfate removal unit recovery by up to 5% and decrease clean-in-place hours and same-day troubleshooting.

Salinity system increases flow assurance

Emerson Automation Solutions has released the Roxar Salinity Measurement System for the sensitive, accurate and real-time measurement of saline water in gas production wellstreams, a press release stated. Through the new system operators can instantly identify changes in the flowstream and the smallest amounts of saline water at never previously achieved levels of sensitivity. This enables the operator to take immediate remedial action to prevent threats to production such as scaling, hydrate formation and corrosion. The onset of formation water and its salinity, if not controlled, can lead to well shutdowns and cost producers millions in unplanned shutdown time. The system, which is a key element of the Roxar Subsea Wetgas Meter and is based on microwave resonance technology, provides quantitative and qualitative real-time salinity measurements in many types of field conditions but particularly in the high gas volume fraction/wet gas flows that characterize wet gas fields.

System built for transfers in extreme conditions

Ampelmann has released its latest Walk to Work system, which has been designed for operation in extreme cold conditions, a press release stated. The N-type, nicknamed Icemann, was designed to safely and efficiently transfer crew in extreme icing and temperatures as low as -28 C (-18 F). The fully enclosed and insulated system is operational in sea states up to 3.5 m (11.5 ft) significant wave height and comprises active motion compensation. The Icemann rotates to 360 degrees and is controlled from the vessel with flexibility in platform landing locations and directions. Walk to Work systems, where workers transfer between offshore platforms and adjacent vessels, are increasingly being used by the offshore industry as a safe and cost-effective alternative to helicopter and basket transfers.

Protecting against corrosion

Belzona has released its encapsulating membrane Belzona 3412. This coating can be brush- or spray-applied onto complex surfaces to protect them from the most severe corrosion, a press release stated. When used in conjunction with Belzona 8411, a release agent/corrosion inhibitor, Belzona 3412 can be cut and peeled back during required maintenance or to check the status of the substrate before being fully resealed with an extra layer. The membrane provides protection to a range of machinery and equipment, from the smallest bearings to the risers of offshore platforms. Belzona 3412’s elasticity and adhesion properties allow it to encapsulate and bond effectively to many types of metallic and painted surfaces. The membrane provides a durable layer of protection against many types of corrosion such as galvanic and crevice. Belzona 3412 also has protection against aggressive environmental factors, including ultraviolet resistance.

System helps avoid storms, improve rig move efficiency

Delmar Systems has released its new RAR Plus and MOOR-Max releasable mooring system. The RAR Plus is the next generation of rig anchor release (RAR) systems, building on proven acoustic release technology by adding key features such as a manual backup release method and increasing the ultimate and release load ratings, a press release stated. The RAR Plus transmits both direct and indirect line tension measurements from internal sensors for real-time display onboard the rig in a user-friendly graphical user interface. The RAR Plus is a key component in the MOOR-Max releasable mooring system. The MOOR-Max system provides a mooring system for mobile offshore drilling units to avoid storms or improve rig move efficiency. It is the only mooring system that combines proven acoustic mooring release technology with efficient proprietary methods. “Not only does the MOOR-Max system allow rigs to significantly mitigate risk by evading cyclonic storms or ice fl oes, but it also reduces critical path time when disconnecting rigs for transit to the next location,” said John Shelton, Delmar Systems vice president of engineering.

100% cloud-based technology to digitize offshore field development

Xvision Software has released FieldAP, the first 100% cloud-based technology for the energy industry providing offshore project managers with an online tool for visual field development, digital planning and cost containment, a press release stated. The online tool is capable of accelerating project timelines by up to 80%, especially during the early concept and FEED phases. These time savings can drive cost savings as high as 70% across the life of the project. FieldAP brings all offshore field development project data—assets and activities, both subsea and topside—into plain sight through easy-to-understand online 2-D/3-D visualizations.

System combines a digital twin of any marine or offshore assets

Bureau Veritas has released its Veristar AIM 3D asset integrity management system based on technology partner Dassault Systems’ 3DEXPERIENCE platform, a press release stated. The new system combines a digital twin of any marine or offshore assets with smart data in a collaborative environment. Veristar AIM 3D will be used in the design, development and implementation of the operational life cycle to refl ect and predict the condition of any asset or fl eet of assets. The system supports risk-based inspection and condition-based maintenance approaches. Veristar AIM 3D provides asset management dashboards for individual ships, rigs, facilities or whole fl eets. This will enable smarter decisions based on better visibility of actual asset condition and performance.

未经允许,不得转载本站任何文章:

石油圈

石油圈