Innovative variable speed solutions for rod pump applications

A rod pump operating at fixed speed captures only part of the available production flow. Pin timers and pump off controllers help optimize production, but stress the rod and increase maintenance costs. Although standard variable speed drive (VSD) solutions provide flexibility they do not allow the lowest operating cost.

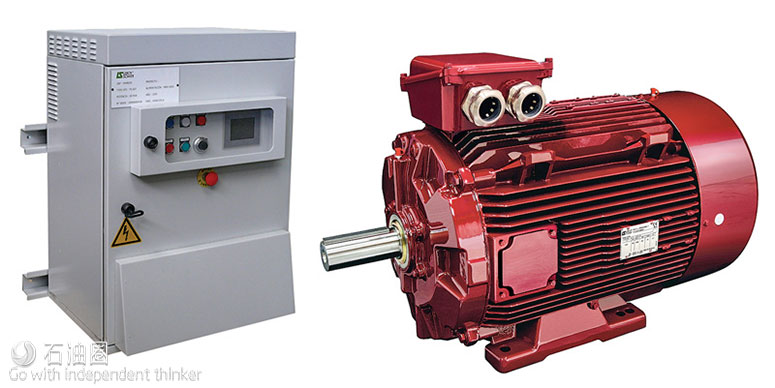

Leroy-Somer VSDs tackle these issues providing higher efficiencies and the possibility to save energy, Fig. 10. The typical operating cycle of a rod pump where the load varies with the rod position leads to poor overall efficiency when using standard induction motor solutions. It has a significant impact on operating costs. In addition, during part of the cycle the rod pump feeds energy back. This is often an issue, with mechanical stress on the system in fixed speed or energy management in variable speed.

Leroy-Somer’s patented variable speed solutions are uniquely designed for rod pump applications and include:

Dyneo synchronous permanent magnet technology that provides higher efficiencies independent to the load.

Powerdrive FX variable speed drive using a unique naturally regenerative technology that feeds any excess energy to the power supply.

Latest comparative measurements between direct on line (without variable speed drives) electric powered rod pumps and rod pumps powered by Leroy-Somer innovative variable speed solutions yielded energy savings exceeding 30% at the same production level.

Leroy-Somer was previously part of Emerson Electric Company. In February 2017, Leroy-Somer and Emerson Industrial Automation USA were acquired by Japan’s Nidec Corporation, one of the world’s largest comprehensive motor manufacturers.

PROACTIVE OPTIMIZATION

Proper selection of an artificial lift system should include an analysis of the individual well’s parameters and the operational characteristics of the available lift systems. Analysis should start when reservoir, drilling and completion decisions are being made; not after the well has been drilled and completed.

Artificial lift system selection service

Schlumberger’s LiftSelect lift method selection service simplifies the process of selecting the artificial lift strategy that best achieves an operator’s goals, based on objective analysis of economic and technical criteria in an integrated engineering workflow. Conventional artificial lift decision-making applications rely on manual workflows with a large amount of data scattered across multiple sources and forms. Sorting through this information and gathering the required pieces is a significant challenge. The LiftSelect service combines these workflows to help operators choose the artificial lift strategy that best suits their well and field conditions, not only for the beginning of the production cycle but for the entire life of the well.

The service uses available data to build reservoir models, well models, and economic performance models. When combined with production data gained through sampling and measurements, these models can be leveraged into a live, integrated asset model that forms the cornerstone of the LiftSelect service. This scientific approach encourages impartial decision-making, free of biases based on historical preferences or opinions for or against a particular artificial lift method. When coupled with reservoir models and network models, the service’s artificial lift strategy calculations ensure lower overall opex/bbl and accelerate production.

The objective of the streamlined workflow behind the service is to facilitate the decision-making process for selecting the most economically appropriate artificial lift strategy. Through the automated workflows and user-friendly interface, the service delivers results and recommendations about the artificial lift approach most likely to achieve the project’s economic expectations. Unlike conventional tools that try to make recommendations based on production and conditions at a single point in time, the LiftSelect service simplifies the engineer’s analysis, forecasting years of production for multiple artificial lift scenarios. Ultimately, this tool allows operators to improve the economics of their wells and fields with strategic decisions about artificial lift methods and transitions.

石油圈

石油圈