When unconventional wells are not performing up to expectations, you can do one of two things:

- Continue to produce at low rates;

- Restimulate the well using a “pump and pray” approach.

A steep decline curve in production performance typically occurs over a three-year (or shorter) period in unconventional wells. The result is an estimated recovery of only 10% or less of available reserves. At that point, you may choose to accept suboptimal production rates, or you may attempt to blindly restimulate the well. The former isn’t satisfying, and the latter is no guarantee of restored production.

Neither option is an effective or efficient approach for managing, or increasing your return on investment, but this has been business as usual— until now。

Now, there is another option.

One that uses a science- and fact-based methodology to help maximize value from wells that have more production to offer

A steep decline curve in production performance typically occurs over a three-year (or shorter) period in unconventional wells. The result is an estimated recovery of only 10% or less of available reserves.

At that point, you may choose to accept suboptimal production rates, drill more wells to try and meet production targets, or blindly restimulate existing wells. None of these options represent an effective or efficient approach for managing, or increasing your return on investment, but this has been business as usual—until now.

The Baker Hughes NextWave™ production rejuvenation solution provides operators with a more sustainable approach to maximizing value from existing shale wells—quickly, efficiently, and economically.

The solution leverages a science- and fact-based methodology to ensure that financial resources are allocated to the wells with the highest probability to be restored to, and even exceed, initial production to boost ultimate recovery. The offering is based on a simple, four-step process that includes candidate well screening and selection, well diagnostics, program design, and wellsite execution—all performed by Baker Hughes experts.

Select and diagnose the best rejuvenation candidates

Not every well benefits equally from a rejuvenation program, so it’s important to build your efforts on a process that uses reservoir and production data to identify the wells that give you the best chance to rejuvenate production and boost ultimate recovery.

The first step is analyzing overall field production data. Then, each well is examined based on a variety of factors including: Productivity,Decline curve,Original completion and stimulation program.

After the best candidates have been identified, each well requires additional analysis to understand the production contribution from the existing fracture stages, along with a comprehensive review of the initial completion and the wellbore’s condition. These efforts can include:

- Examining the original completion and stimulation;

- Conducting a thorough wellbore cleanup;

- Verifying the integrity of the casing and cement;

- Creating a diagnostic profile of existing fractures;

- Gathering additional formation evaluation data if needed.

Design the right program

You may find, based on the well examination, that the cleanup process itself improved production, or that artificial lift can restore the well to desired production levels.

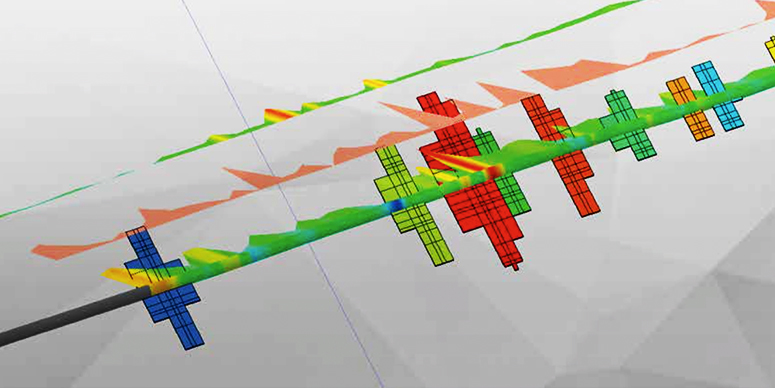

But if refracturing is needed, the production profile data from existing stages can be combined with reservoir models to capture the full scope of subsurface data, giving our experts the insight to design the most effective rejuvenation program. Program goals often include:

- Restimulating underperforming intervals;

- Stimulating previously untreated zones to increase reservoir contact;

- Reestablishing connectivity to the wellbore through pre-existing fractures.

This process ensures that you can effectively manage costs by limiting your reinvestments to viable refrac candidate wells that can be rejuvenated— at a fraction of the cost of new wells—not just once but multiple times.

Execute in the field

Effective, efficient field execution is the final crucial step in the refracturing process. Baker Hughes has a full arsenal of completion and stimulation technologies and services to help prepare any well for refracturing, to close off existing stages that are not part of the refrac design, and to isolate the desired frac stages to effectively restimulate the well.

During the refracturing process, monitoring fracture propagation is important to ensure the success of the job. This real-time data, combined with post-refrac analysis, is crucial to refine and enrich the reservoir models for the next refracturing operation. It takes a multi-well approach to identify the most effective rejuvenation treatments, and to help further drive efficiency, reliability, and improved ultimate recovery.

An equally important part of executing the field program is managing wellsite operations. Baker Hughes assigns a dedicated wellsite coordinator and project manager responsible for overseeing the project, resulting in better execution efficiency and improved overall communications.

Capture even greater value with flexible commercial models

We know that each unconventional shale play operator has different business drivers. That’s why we offer commercial models that increase economic value to you by aligning our success with the success of your well.

This type of model is possible when well candidate selection and evaluation are a collaborative effort with your service provider, so both sides understand the potential risks and rewards. Extending collaboration to the design and execution of the rejuvenation program ensures shared ownership of the entire process.

The best refrac solutions offer a choice of commercial models:

- Straight sale;

- Execution risk based on service delivery to specific key performance indicators;

- Production risk based on specified production rates and volumes.

Baker Hughes offers these flexible models because we strongly believe in our ability to deliver greater recovery from your wells

With an approach leveraging new workflows for rejuvenating existing wells, the industry can achieve production and recovery levels needed to sustain unconventional plays in an environment of lower oil prices. We can also achieve the efficiency we have been seeking by drilling longer, cheaper wells. In this instance, we are replacing more wells with more productive wells.

We are replacing field experimentation with analysis and planning. We are replacing horsepower with brainpower.

石油圈

石油圈