MPD and continuous circulation technology overcome deepwater challenges

Previous wells drilled by Murphy Oil Company offshore Sabah, East Malaysia, using conventional open wellbore drilling technology had experienced well control events and significant non-productive time. Conventional drilling problems encountered in the area’s shallow, multi-layer sandstone formations included kicks, stuck pipe, lost mud circulation, and differential sticking.

Implementing managed pressure drilling (MPD), as well as continuous circulation system (CCS) technology and processes, successfully mitigated these formation pressure-related challenges so that target depths could be safely and efficiently reached. A 13-well deepwater MPD program eliminated formation pressure problems seen on conventional drilling operations, and in the process performed the industry’s first deepwater managed pressure cementing (MPC) operation.

The innovative program used dynamic MPD formation pressure analysis techniques and LWD tools to reduce uncertainties in the extremely narrow formation pressure drilling windows.Operations were conducted from a deepwater moored spar platform in 4,400 ft (1,341 m) water depth. The 13-well campaign drilled 27 hole sections using MPD and CCS technology and methods.

Some sections were considered undrillable without MPD technology due to the narrow pore pressure/fracture gradient (PP/FG) window, high gas levels, and mud losses on some sections. A statically underbalanced, dynamically MPD overbalanced mud weight was used to widen the operational drilling BHP window and achieve the required BHP control.

SANDSTONE CHALLENGE

The field’s reservoirs are formed by relatively shallow, multi-layer sandstone formations at 8,202 to 10,006 ft (2500 to 3050 m) TVD. Production began in 2007, and was followed by a water injection program. Faulting has compartmentalized the reservoir, and there is a mix of depleted compartments that have been isolated from the water injection, and where virgin reservoir pressures may be encountered when drilling new wells. Dynamically overpressured sandstones also occur where water injection has supercharged the formation.

This formation pressure regime makes it difficult to predict the PP/FG window. The uncertainty has significant repercussions. For example, if a kick occurs when drilling through a weak, pressure-depleted sandstone layer into a lower overpressured zone, it may result in an underground blowout in the weak sandstone.

A narrow drilling pressure window also increases the chances of lost mud circulation during liner runs and cementing. It is difficult to achieve good zonal isolation above a depleted zone, as the heavier cement slurries can be lost to weaker formations. These challenges are compounded by well designs with high angle or horizontal hole sections that require considerable hole cleaning in the smaller production hole sections.

MPD/CCS SELECTION

This complex combination of depleted formations, narrow PP/FG windows, and high hole angle inclinations created a significant challenge when using conventional drilling practices. To improve safety and efficiency of operations, a drilling campaign was developed using MPD with a CCS. The initiative had several objectives, including reducing risk and NPT associated with lost mud circulation, kicks, stuck pipe, and wellbore collapse. MPD technology was implemented to improve management of downhole pressure and overbalance, hole cleaning in the high-angle wells, and event detection.

The MPD approach combined active, continuous control of hydrostatic and applied annulus pressure and flowrates while maintaining continuous drilling fluid circulation in a closed-loop circulating system. Techniques included dynamic MPD well control and formation evaluation, along with dynamic managed pressure cementing (MPC). MPD annular pressure and flowrate control was combined with a continuous circulating system using drillstring subs.

MPD/CSS EQUIPMENT

Installing the MPD package on the deepwater moored spar platform required detailed planning. The equipment occupied significant deck area and loading capacity, and hot work activities were restricted due to ongoing production from live wells. Surface MPD equipment was consolidated on the same deck to minimize interconnecting pipe work. Pipe work size was maximized to reduce the frictional flow pressure drop across MPD surface lines.

Continuous circulation system

The addition of CCS enabled maintenance of constant bottomhole pressure (CBHP) across the open hole section and provided continuous hole cleaning/cuttings transport during drill pipe connections. It also stabilized BHP and bottomhole temperature (BHT) conditions.

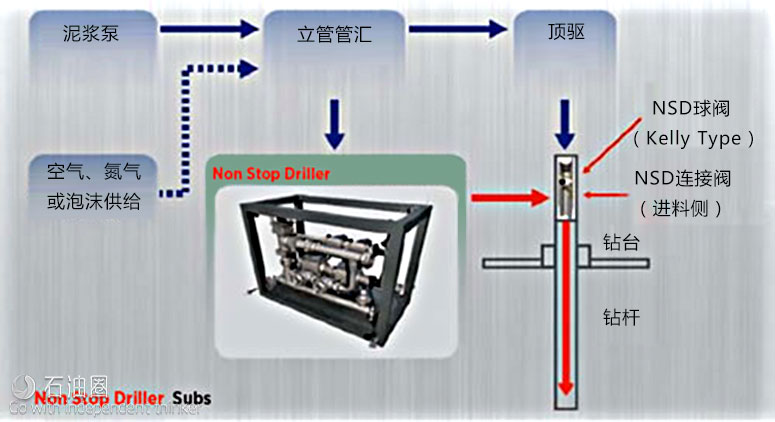

The CCS used rig pumps to provide continuous circulation down the drillstring while making or breaking drill pipe connections, Fig. 1. The system consists of a ball valve and a custom-designed high-pressure side entry valve housed in CCS drill pipe subs. Circulation is maintained throughout the connection by circulating into the side entry valve via a manifold interfaced with the rig standpipe manifold, a hose, and quick connector. A ball valve in the CCS sub is closed to bleed off pressure above it, allowing the drill pipe connection to be broken and a new stand made up while full circulation continues via the side entry valve.

MPD manifold

The MPD system’s pressure control and metering manifold (PCM) achieves accurate BHP control of +/– 30 psi and minimum liquid return flowrates of 1,700 gpm with an ASBP window of 15 to 1,350 psi.

The manifold uses a pressure relief system upstream of the PCVs and the Coriolis mass flow meters to protect the formation, casing, subsea and surface equipment from overpressure conditions. Four- and 8-in. Coriolis flow meters are used to measure drilling fluid return flowrates, along with fluid temperature and density. All remote-actuated valves are operated via the MPD SCADA system control panels, where positions are monitored and displayed.

石油圈

石油圈