Chemical enhanced-oil-recovery (EOR) methods such as polymer and alkaline/surfactant/polymer (ASP) flooding are generally not considered suitable for oil viscosities greater than 100 or 200 cp. However, this perception is changing, in particular because of field results from a number of chemical EOR pilots or full-field floods conducted in Canada in higher-viscosity oil. The aim of this paper is to review some of these projects.

Introduction

Canada is well-known for its heavy-oil and bitumen reserves. Most of the bitumen reserves are exploited using thermal methods, such as cyclic steam stimulation or steam-assisted gravity drainage, while heavy oil is exploited mostly using cold production methods, such as cold heavy-oil production with sand. Cold production leads to recovery of less than 10% of original oil in place (OOIP). Thermal methods are not always applicable, in particular when the pay is thin. In that case, alternatives such as chemical EOR are required to increase recovery. The two main chemical EOR processes are polymer and ASP flooding.

In the past 10 years, several chemical-flooding projects have taken place in Canadian heavy-oil fields. The most successful of these is the Pelican Lake project, which is currently producing more than 60,000 B/D, much of it through polymer flooding. But other less-well-known projects such as the Taber South project, the Mooney project, and the Seal project are all interesting and worthy of discussion. For full descriptions of these fields, please see the complete paper.

Projects

Pelican Lake Polymer Flood.

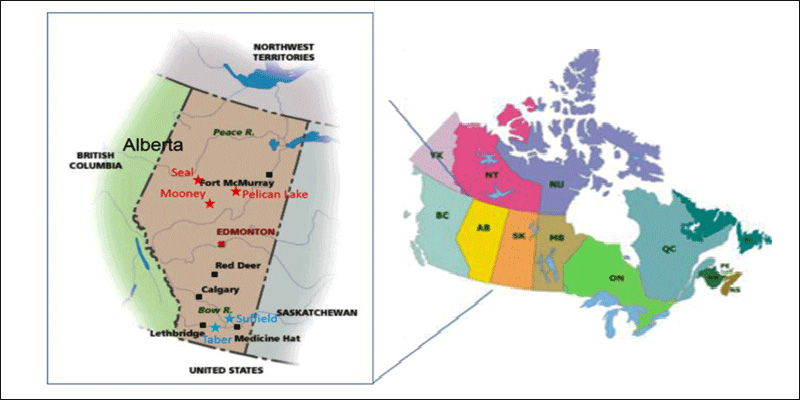

The Pelican Lake field is approximately 250 km north of Edmonton, Alberta, Canada (Fig. 1). The recovery factor for primary production remained low even after the introduction of horizontal drilling. Thus, a first—unsuccessful—polymer flood was attempted in 1997, after which waterflood was also piloted. The waterflood managed to increase oil production but with high water cut. Thus, another polymer pilot was started in 2005.

Polymer injection started in May 2005. The responses were excellent, with rates going from 18 to 232 BOPD in the first well, from 9 to 364 BOPD in the central well, and from 16 to 139 BOPD in the last well. The water cut increased slowly and moderately in all three wells. The operators estimate that polymer flooding will increase the recovery factor to 20 to 30% of OOIP.

Mooney Bluesky A Polymer Flood. The Mooney field is in northwestern Alberta (Fig. 1). The operator considered polymer flooding as a way to improve sweep efficiency and reduce water production. A pilot composed of two injection wells and three production wells, all horizontal, started in November 2008.

The polymer flood was able to increase production and maintain a plateau for a few months in the two wells closest to the injection wells. However, water breakthrough occurred within 4 months in the confined well and within 6 months in the other well, and the water-cut increase was very sharp.

Further modeling suggests that polymer-flood recovery could vary between 17 and 25% of OOIP; the recovery in the central well of the pilot was approximately 12% of OOIP as of March 2013.

Seal Bluesky Polymer Flood. The reservoir in the Seal area of the Peace River oil-sands region in northern Alberta (Fig. 1) has been developed with more than 270 horizontal producers since the pool was discovered in 2001. The wells achieve good initial rates—given the high oil viscosity—of 100 to 200 BOPD before declining.

A polymer-flood pilot with three injectors and four producers was initiated in October 2010. Production responses started in June and July 2011 in the two confined wells, with oil rates increasing from approximately 30 BOPD to a maximum of 135 BOPD in one well and from approximately 50 BOPD to a maximum of 155 BOPD in the other. What is more surprising is the water-cut evolution; it started increasing at the same time as the oil rate or even slightly before and has been increasing very slowly since then. In early 2013, it was at 40% in one of the wells and still only 10% in the other. Polymer apparently broke through in the producers sometime in late 2011 or early 2012.

At the end of November 2013, the recovery in the two confined producers was approximately 5 and 6% of OOIP, respectively; the estimated ultimate incremental recovery is 8.8% of OOIP, which would bring the total recovery to 14.3% of OOIP.

Taber South Mannville B ASP Flood. This project (Fig. 1)—the first fieldwide ASP flood in Canada—started in May 2006.

In 2004–05, the cumulative production was 16.9 million bbl and the recovery was approximately 38% of OOIP. There was no pilot, and the injection of an ASP solution started in May 2006 in the whole pool. At that time, estimated pool recovery was 38.7% of OOIP.

The production response started in November 2006, and the pool eventually saw its production rise from 300 BOPD to a maximum of 1,330 BOPD. At the same time, water cut decreased from 98 to 84%.

Estimated incremental oil recovery for the project climbed as high as 16% of OOIP but was reduced several times because of operational issues. It now appears to stand at 11.1%.

Suffield Upper Mannville UU ASP Flood. The Upper Mannville UU pool is one of many similar pools in the Suffield area (Fig. 1). The pool was developed with initial production in 1996. Water injection was initiated in 1998. When the operator started considering ASP flooding at the beginning of 2006, oil production was approximately 300 BOPD, with a water cut of 60%. Cumulative production at that point was 320,000 bbl, or slightly less than 10% of OOIP.

Because of the small size of the pool, there was no pilot, and the injection of an ASP solution started in May 2007.

The response in terms of oil rate is rather muted, although it could be argued that production would have declined had the ASP injection not taken place. The picture is somewhat distorted in that one very good well, which was producing more than 100 B/D 5 months before the beginning of the injection, saw its production fall suddenly to 10 B/D when the injection started. This well later went back to the same 100 B/D of production, but it is doubtful that this can be attributed to the ASP injection.

The recovery factor was 14.1% of OOIP when the injection started; it is now almost 30% of OOIP. According to the operator, the expected recovery factor for the primary recovery with waterflood was 20% of OOIP and the incremental recovery from the ASP flood is greater than 10% of OOIP.

Conclusions

A review of the five chemical EOR projects in heavy oil in Canada—three polymer floods and two ASP floods—has led to the following conclusions:

Chemical EOR is a viable solution to increase production and recovery in heavy oil.

For polymer flooding, the process has proved to be efficient for viscosities up to 10 000 cp.

For ASP flooding, the process has not yet been tested at those high viscosities but is efficient at viscosities up to a few hundred centipoise. There is no reason that it would not be as efficient as polymer flooding at higher viscosities.

石油圈

石油圈