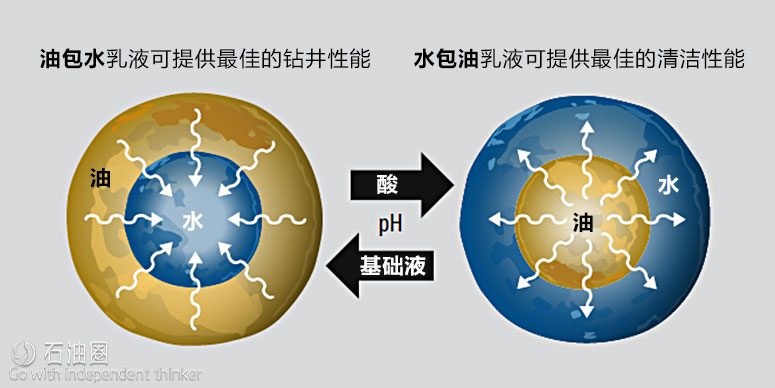

The advantages of the FAZEPRO system are realized not only in drilling through the pay zone at high performance but also in the completion phase. By simply adjusting the pH of the breaker solution, the wettability of the filtercake transforms from an oil-wet state to a water-wet state. Once the filtercake surface is water-wet, the bridging agent can be easily and completely removed.

The system also mitigates the formation damage and completion impairment of many gravel packs, which have historically restricted lift-off and flowback in addition to blocking uniform accessibility of breakers to the filtercake. For water injection wells, the FAZEPRO system enables immediate postcompletion injectivity without preproducing the well to clean up the reservoir.

The PRIMO-FAZE* low-oil/water-ratio reversible nonaqueous reservoir drill-in fluid (RDF) system expands the FAZEPRO system operating density window. It maintains the same reversibility while enabling higher-volume internal phases to replace solids required to attain a given density.

Thorough destruction of oil-base filtercakes

The FAZEPRO system chemical package comprises two easily converted chemicals—FAZE-MUL* primary reversible emulsifier and surfactant and FAZE-WET* primary wetting agent and fluid loss control additive.

The FAZE-MUL surfactant is the industry’s only emulsifier capable of being reversed from an oil-wet to a water-wet state. It facilitates the transformation through a change in pH; during the change from oil-wet to water-wet, the emulsifier becomes a surfactant. This reversal mechanism permits total destruction of the filtercake, removing the barrier between the formation face and the wellbore. This helps regain reservoir connectivity and establish increased productivity or injectivity.

Simplified dual approach to filtercake removal

The distinctive chemistry of the FAZEPRO system simplifies both the dispersion and dissolution approaches to filtercake removal. Field data has shown that destroying a FAZEPRO system filtercake is easier compared with destroying a filtercake deposited by conventional water-base RDFs. While a conventional aqueous-base RDF requires locating and then breaking down polymers of various molecular weights, the invert emulsion is wholly responsible for the integrity of a FAZEPRO system filtercake. That means destruction simply requires separating the oil and water phases.

Whether through dispersion or dissolution, what results is a filtercake that is quickly and thoroughly destroyed, leading to a smooth completion operation.

Applications

(1)Openhole completions requiring sand control;

(2)Openhole injection wells;

(3)Openhole completions requiring acid stimulation.

Benefits

(1)Promotes faster drilling;

(2)Delivers stable, high-quality wellbore;

(3)Simplifies filtercake removal;

(4)Minimizes equipment requirements and eliminates postcompletion remedial treatments;

(5)Improves delivery of openhole gravel-pack (OHGP), stand-alone screens, and other complex completions;

(6)Maximizes ROI by enhancing production and injection rates;

(7)Enhances HSE profile by minimizing generated waste volumes.

Features

(1)Invert-emulsion drilling performance;

(2)Water-base filtercake removal performance;

(3)Mild-pH, engineered-delay breakers and controlled breakthrough;

(4)Stable, inhibitive drilling properties;

(5)Simple pH adjustment for water-wetting filtercake surface;

(6)Simplified single-stage cleanup.

The aim of the MUDSOLV NG service is to design the best possible openhole filtercake cleanup program for your specific application. The service ensures the proper treatment of the FAZEPRO system during completion. MUDSOLV NG service is a key component in the comprehensive M-I SWACO openhole completion portfolio that also includes gravel packs, displacements, and specially engineered proprietary software packages.

Performance metrics and laboratory verification testing are fundamental to this design. Combined with the latest analytical tools and breaker chemistries, the MUDSOLV NG service approach consistently delivers uniform, controlled, and complete removal of filtercakes in the most challenging and complex completions.

For immediate dissolution

FAZE-OUT* reversible-system water-base filtercake breaker dissolves FAZEPRO system filtercakes in injector or production wells. It can be mixed at the rig site and is designed for total dissolution of invert-emulsion filtercakes, thus enabling immediate flowback through restrictive openhole completions such as premium screens and gravel packs.

For short delays prior to dissolution

FAZEBREAK* chelant-base filtercake breaker system disperses residual deposited FAZEPRO system filtercakes while completing zones. Formulated primarily for postspotting in OHGP completions, the FAZEBREAK system delays the reversal of the residual FAZEPRO system solids from an oil-wet to a water-wet state, the water-wetting of residual solids, and the initiation of the dissolution or chelation of the bridging agent. These features allow placing the breaker during the completion and subsequent removal of tubulars without excessive losses.

For long delays prior to dissolution

FAZE-AWAY* reversible invert-emulsion filtercake breaker system dissolves FAZEPRO system filtercakes. The FAZE-AWAY system is recommended for openhole producer or injector completions using standalone or expandable screens as well as after an OHGP completion. This breaker is designed to delay breakthrough for extended time periods and can be used in formations that are sensitive to water-base breaker systems.

Case Study1

Challenge

The operator drilled an injector with a conventional oil-base drilling fluid, which provided the required inhibition and lubricity. However, after days of circulating and cleaning the wellbore, the acid breaker treatment was found unsatisfactory, and injection volumes were highly inadequate.

Solution

For its next injector well, the operator deployed the FAZEPRO and FAZE-OUT systems over the openhole section.

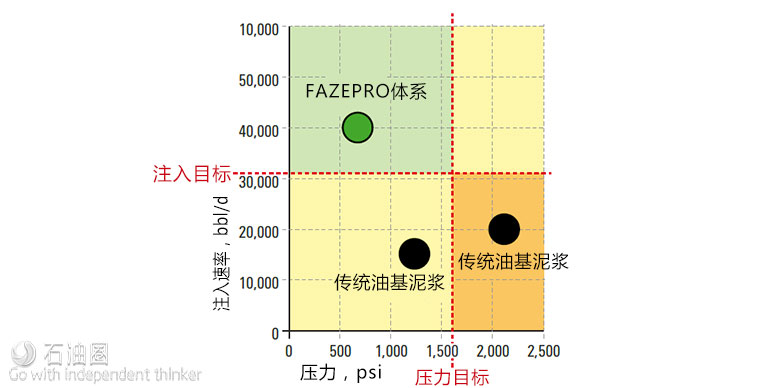

Results

The FAZEPRO system was used for drilling the reservoir interval and helped achieve the highest injectivity rate and lowest injection pressure in the area. The injection performance resulted in 30% more seawater at 40% less pressure than expected. This was also more than twice the amount injected on the best offset at 30% of the injection pressure.

Further, using the FAZEPRO system eliminated the costly rig and coiled tubing time, as well as the hazards, of conventional acid filtercake removal treatments.

Case Study2

Challenge

After attempting to destroy a FAZEPRO system filtercake using acid on an OHGP producer, an operator realized that a more controlled treatment was required. The acid treatment had been performed postgravel pack with a short stinger and resulted in immediate breakthrough, allowing the acid to bypass the majority of the filtercake.

Solution

On subsequent wells, the FAZEBREAK system breaker was used to enable uniform placement across the entire interval.

The Results

The slow reaction rate of the FAZEBREAK system provided sufficient control and resulted in no unplanned losses, even during the gravel-pack operation. This method was used on a total of six OHGP completions with equal results.

The FAZEBREAK system was allowed to diffuse through the gravel and destroy the filtercake over several days. The wells produced above expectations and without the need for postcompletion intervention.

石油圈

石油圈