定向井作业经常发生井筒轨迹偏离等问题,技术和观念的落后是原因。为此,Motive公司拿出了新的方案。

来自 | E&P

编译 | 张德凯

在非常规油气藏的开发中,开发商所面对的最棘手问题无疑是钻井轨迹偏离问题,由于地层条件复杂,实际钻井轨迹通常会偏离预设的钻井方案。定向井技术发展的滞后是造成该类问题的主要原因,目前来看,定向井技术已经远远落后于水平钻井中的其他技术。

为了解决该问题,Motive钻井科技公司研发并推出了新型导向技术,可以在钻台操控,实现钻头的自动决策导向。

自动决策系统在很多行业中的应用已经非常普遍,包括医疗领域、电子游戏、汽车&飞机自动驾驶、制造业、物流、导弹导航等,而且其应用范围也正在日益扩大。在过去的五年中,Motive将自动决策系统应用于钻头导向系统,并在北美成功地为多家油气公司进行了水平井、大位移井的钻井作业,总钻进长度达610000m。作业结果表明,新型钻井系统能够显著降低钻井时间、提高钻进精确度、提高油藏生产潜能,在某些案例中作业人员数量也得到降低。

钻进提速

在水平井的钻进过程中,作业专家必须能够快速做出方案调整决策,在何时转动钻杆、在何时改变钻进方向都是非常重要的。而这些决策的制定也必须建立在大量数据的基础上,包括钻头游动趋势、马达状况、防碰撞导向、狗腿度以及偏离预定轨迹造成的产能变化趋势等。此外,钻井专家连续分析的实时数据还包括γ测井数据、大钩载荷、地面扭矩、泵压、流率、轨迹测量数据、临井间距等。

定向钻井工程师在多年的实际工作中积累了大量的工作经验,这是他们能及时根据现场数据变化、根据直觉做出决策的依仗。然而,最优秀的定向井工程师不仅要凭经验、直觉做出决策,还要进行大量的计算,才能得到更优的结果。诺贝尔奖得主Daniel Kahneman在其著作《Thinking Fast and Slow》中写道:很多时候,人们都太过于依赖直觉。他们在处理问题时,往往会根据直觉做出判断,而不会进行充分的思考,即使在面对重要决定时也是如此,所以决策结果受人为因素影响极大。定向井作业也是如此,不同作业人员的作业结果总是差别极大。

自动化过程

Motive研发的钻头自动导向系统,使用高水平计算机进行大量数据处理,得到的结果更合理,对于定向井钻井结果有着质的提升。作为提升定向井质量的关键部分,该系统不仅能较工程师更快得出结果,还能提供连续的计算数据。此外,该系统还能提供大量、额外的分析和自动化计算,根据动态分析数据、开发商的要求,给予钻井工程师详尽、逐步的转向/钻进操作指导,大大提高作业效率。

相比于人工计算,计算机的速度和准确率都要更高,这是人工计算无法达到的,因此实时决策的制定更加准确,油藏价值也能得到最优化。该系统的自动计算过程中考虑影响因素非常全面,包括钻井时间、作业时间延误风险、油藏生产潜能等;另外,为了降低井筒的摩擦扭矩、提高钻进速率、最大化水平井触及范围、降低水平段漏失、防止产率降低,井筒的弯曲程度也是定向计算中需要考虑的重要因素,而这些在人为计算中往往会被忽略,造成不必要的产能损失。

该系统根据钻井工程师的作业计划,连续调整钻头钻进方向,同时给出实时反馈,提高作业效率。由此可见,该系统的自动化达到了前所未有的水平,可持续提高定向井作业人员的工作表现,根据实际数据做出决策,而不是根据经验、直觉做出调整。

案例研究

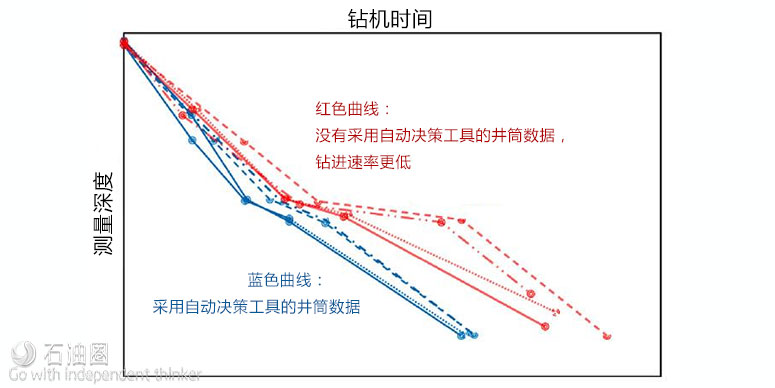

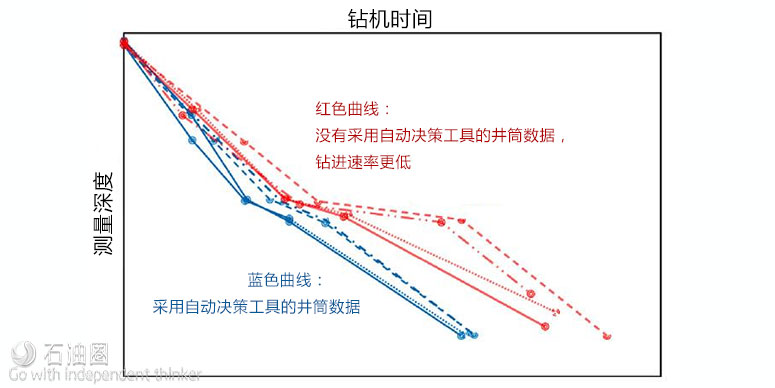

下图所示为Eagle Ford盆地一位开发商采用该系统进行测试的结果。

在此次测试中,该油田使用两个相同的钻机,在油藏性质相同的区块,分别钻四口井。其中一台钻机使用Motive的自动决策工具,另外一台钻井则由钻井工程师掌控。所有的钻井参数均相同,包括钻头、井下钻具组合、井筒轨迹设计等。

结果表明,采用自动据测工具能够使钻井速率提高25%,同时准确率也得以翻倍。

自动决策工具提升钻进速率25%,提高钻进准确率2倍

目前来讲,该系统还无法做到对井筒的每一项定向井任务进行自动导向,但通过与经验丰富的钻井工程师合作,把该系统强大的计算能力与实际作业经验结合,这将极大提高定向井作业效率、降低作业风险,为油气开发商带来最佳作业表现。由于自动决策系统的引入,定向井作业中可能也需要定义新的角色,对变化管理以及新科技接受的程度也将是该系统推广的关键影响因素,虽然有一定的风险,但回报将是丰厚的。自动决策系统除了能够提高单井的产能和产率以外,还能放大优秀钻井工程师的作业表现:该系统可以自动进行大量计算,单个钻井工程师就可同时远程操控多个定向井钻井作业的进行。

由于计算和决策制定得到了完美的分工,同时配合自动报告、邮件提醒等功能,整个决策制定团队(包括作业现场和办公室内的人员)就能实时掌控井筒的历史数据、实时计划调整状况以及进一步的钻井计划,钻井工程师可同时执行其他任务,作业效率大大提高。该系统能够将计算结果在可视化界面上进行2D、3D显示,通过浏览器或者移动设备的软件就能实时观察。

无论操控人员身在何处,定向钻井的完全可视化对整个作业团队都可见,该系统还能将作业结果反馈给开发商,进一步提高钻井工程师的作业效率。

正如自动决策系统能够为医生优化治疗方案、使汽车更安全一样,该技术同样能提高复杂地层条件下水平井钻井的效率和连续性。

One of the most significant problems identified by oil and gas operators in unconventional plays is the inability to follow a prescribed well path consistently and to hit and stay within the targets identified collectively by the company’s geologists, geophysicists and engineers. One reason is that directional drilling technology lags behind other technical advances that drove the tremendous growth in horizontal drilling.

To address this problem, Motive Drilling Technologies developed a directional drilling bit guidance system automating decision-making at the rig. Automated decision-making has been used for making medical decisions; for playing games (such as Jeopardy, chess, poker or the ancient game of Go); for automatically piloting cars and planes; for manufacturing, shipping and missile guidance; and for much more. Over the past five years Motive has applied automated decision-making to its bit guidance system’s development and subsequently to the drilling of more than 610,000 m (2 million feet) of horizontal and extended-reach wells for more than a dozen oil and gas companies across North America. Use of the system has resulted in wells drilled with more consistency in less time, with more accuracy and more production potential and, in some cases, with less personnel.

Drilling rates are so fast that even the best directional drillers simply do not have the time to perform all the necessary calculations required to make the absolute best directional drilling decisions. The performance of directional drillers often is quite variable, costing the industry billions of dollars each year due to slower drilling speed, increased tortuosity and lost production potential.

Need for speed

While drilling horizontal wells, directional drilling experts must make quick decisions determining when to rotate the entire drillstring and when to adjust the direction of the drillstring by sliding. These decisions are based upon numerous inputs, including bit walk tendencies, motor yields, anti-collision guidelines, dogleg severity and future production consequences related to deviation from the target path. In real time the directional driller continuously analyzes data including gamma ray logs, hook load, surface torque, pump pressures, flow rates, trajectory measurements, distance to nearby wells and much more.

Good directional drillers rely upon their expertise developed over many years as apprentices to more experienced drillers. This results in an environment where most directional drilling decisions are made quickly based on the individual’s experience and an acquired intuition. However, the best directional drillers also know when they must move beyond intuition and shift to performing more effortful geometrical computations to make good decisions. Nobel Prize-winning author Daniel Kahneman wrote in his book Thinking Fast and Slow that in many situations humans tend to rely upon intuitive thinking too much. They are not willing or do not have the time or energy to switch to more effortful thinking, even when it is required for better decision-making. This unwillingness to adapt behavior contributes to the large variation in performance often seen while drilling horizontal wells.

Automated process

The bit guidance system developed by Motive uses a high-performance computer to provide a more data-driven automated decision-making process, delivering the necessary improvement in directional drilling performance. As a foundation for better decisions, the system automatically performs standard directional drilling calculations previously done by the directional driller but calculates them continuously and faster than humans are able. In addition, the system provides a tremendous amount of additional analysis and automatically provides the driller with step-by-step slide/rotate guidance based on the dynamic analysis together with parameters set by the operator. The machine can run calculations on millions of possibilities/permutations that a human cannot do, thereby making the best decision to maximize value. The automated decision considers such variables as drilling time, lost-time risk and future production potential. Additionally, tortuosity of the wellbore is factored into each directional decision to reduce torque and drag on the wellbore, enable higher drilling rates, extend the maximum reach of laterals and reduce sumps in the lateral that impact production efficiency. This degree of analysis is rarely even considered by human directional drillers.

The system continuously adjusts the guidance based on driller’s actions and provides real-time feedback to enhance his or her performance. This level of automation consistently improves the driller’s ability to maximize value to the operator independent of experience.

Eagle Ford case study

Figure 1 shows the results of a case study designed to test the system for a client drilling in the Eagle Ford Basin. Two identical rigs were mobilized in the same area and drilled four wells each. One rig used Motive’s decision automation tool, and the other rig drilled the wells without decision automation. All other parameters were the same, including bit, bottomhole assembly and well paths. The rig using automation drilled 25% faster and with twice the accuracy.

The system does not completely automate every single task of the directional driller. But the computational power of the system combined with the experience and intuition of the directional driller provides oil and gas operators with the best opportunity for consistent performance at higher levels while mitigating risk. With the introduction of decision automation, new roles might need to be defined, and an emphasis on change management and new technology acceptance is critical. However, the rewards are great. In addition to the gains in performance on an individual well basis, the expertise of the best directional drillers can be scaled. With the system performing all the heavy computational lifting, a single expert directional driller can guide multiple wells from a single location.

With this distributed system, the entire decision-making team (on the rig and in the office) is continuously informed about past, current and dynamically planned future directional drilling activities using automated dynamic reporting, email and text notifications, freeing the directional driller to perform other tasks. The system provides this transparency through 2-D and 3-D visualization interfaces that are available both through a browser and iPad app.

By providing complete directional drilling transparency to the entire team regardless of location, the system returns operational control back to the operator and provides better utilization of the best directional drillers.

Just as decision automation is helping doctors provide better treatments and cars to be safer, this technology has proven to improve the performance and consistency of drilling horizontal wells in today’s tough environment.

未经允许,不得转载本站任何文章:

石油圈

石油圈