Baker Hughes Incorporated (NYSE:BHI) announced today the introduction of its DEEPFRAC? deepwater multistage fracturing service, which can save operators hundreds of millions of dollars in offshore developments through unprecedented efficiency gains across the completion phase. Using multiposition sleeves and patented flowback control technology, the service accelerates or eliminates certain steps of conventional multizone completion operations and enables rapid stimulation of 20+ stages. This translates into significantly greater reservoir contact, with an average OPEX savings of USD 30 to 40 million per well.

Proprietary flowback control media is incorporated directly into the multiposition sleeve’s production ports to enable long-term, sand-free production without the need for conventional sand screens. (Photo: Business Wire)

“Historically, operators who needed to stimulate their offshore wells were faced with complex completion operations that could take longer than a month and with costs approaching a hundred million dollars,” said Jim Sessions, Vice President, Completions at Baker Hughes. “By adapting some of the technologies and techniques that delivered game-changing efficiencies in unconventional land to an offshore service, we’ve enabled a new level of deepwater completion design flexibility and streamlined operations—all without compromising our commitment to safety and compliance.”

Typically, after a deepwater well has been drilled, the subsequent completion phase involves multiple, time-consuming steps. In contrast, the DEEPFRAC service eliminates casing and cementing operations and simplifies fluid logistics by using ball-activated, multiposition sleeves that can be installed in openhole wellbores containing drilling mud. And, unlike conventional offshore systems’ complicated tool running procedures and extensive mechanical manipulation requirements, no tool movement is needed during the DEEPFRAC service’s stimulation process. The sleeve’s ball activation enables continuous pumping from the first stage to the last, cutting the lower completion phase from weeks to days.

Conventional offshore stimulation systems are often limited to only five zones or ‘stages’ and these systems lack configuration flexibility that often results in uneven treatments and creates long sections of ‘dead space’ that cover up hundreds of feet of viable pay. The sleeves used in the DEEPFRAC service are modular and flexible, enabling placement of 20+ tightly-spaced stages across the pay zone to ensure more uniform treatments and to maximize reservoir contact.

After stimulation operations are complete, Baker Hughes IN-Tallic? disintegrating frac balls allow production to flow without intervention. Patented Baker Hughes BeadScreen? proppant flowback control technology built directly into the DEEPFRAC sleeve’s production ports provides increased reliability over conventional sand screens through higher burst/collapse ratings and improved erosion/plugging resistance, helping to ensure long-term, sand-free production.

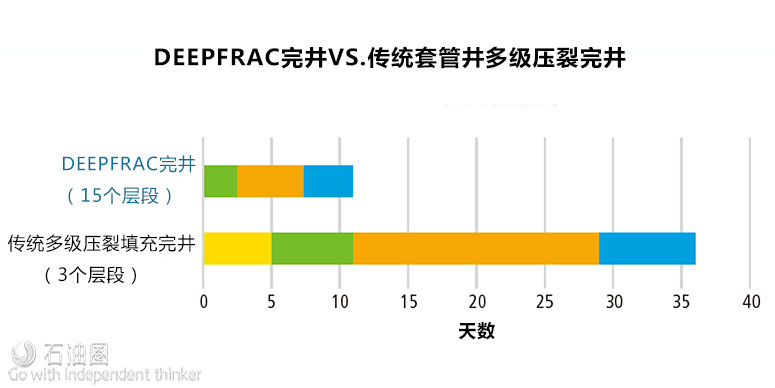

On a recent job, the DEEPFRAC service saved an estimated 25 days rig time and USD 40 million on a first-ever 15-stage deepwater completion in the Gulf of Mexico’s Lower Tertiary.

The DEEPFRAC service is the latest example of Baker Hughes’ strategy to improve well efficiency, optimize production and increase ultimate recovery.

DEEPFRAC Service Saved an Estimated 25 Rig Days and USD 40 Million in First-ever 15-stage Deepwater Completion

A major operator working in the Gulf of Mexico was looking for a way to significantly reduce OPEX across its Lower Tertiary developments. While deepwater plays can be lucrative investments, these reservoirs must be stimulated in order for them to produce. The typical approach is to perform a cased-hole multizone frac-pack completion that can take more than a month of rig time and can cost up to USD 100 million—or more.

Conventional lower completion tools, which are used to create the interface with the reservoir and to deliver stimulation treatments, are typically limited to only five zones, resulting in uneven treatment distribution across long intervals. They also have configuration requirements that create ‘dead space’ along the wellbore, restricting reservoir contact.

Recognizing a huge opportunity to reduce costs and also improve pay zone contact, the operator worked closely with Baker Hughes to explore alternative techniques and technologies for completing and stimulating its wells.

The target well had been drilled to more than 25,000-ft (7620-m) total measured depth (TMD) in 10,000 ft (3048 m) of water. Some of the operator’s requirements included:

1.perform an openhole completion;

2.deliver treatments to 15 stages in a single trip, and at significantly lower cost than the status quo;

3.provide proppant flowback control without using conventional sand screens

4.enable flowback without post-treatment intervention

The DEEPFRAC service accelerated and even eliminated entire steps of the completion process, saving the operator an estimated 25 days of rig time and USD 40 million compared to the average time and cost for a conventional cased-hole multizone completion.

The combination of the stage count requirements and openhole nature of the completion were unprecedented for offshore environments. Jobs of this nature had only ever been performed on land. With significant field-proven experience in these types of applications, Baker Hughes recognized that the best starting point for this challenge was its ball-activated multistage fracturing sleeves. Engineering teams worked to adapt the technology not only to meet the operator’s specifications, but to also meet deepwater traceability requirements. They also incorporated patented BeadScreen? proppant flowback control technology directly into the new sleeve as an alternative to using conventional sand screens.

The customized tools are key enabling technologies of the new DEEPFRAC? deepwater multistage fracturing service, which was used to complete the target well.

The service’s specially-designed DEEPFRAC sleeve has three positions: closed for run in, frac ports open for treatment delivery, and frac ports closed with production ports open for flowback. IN-Tallic? frac balls are used to shift the sleeve and then disintegrate downhole, enabling intervention-free production. And unlike conventional screens that can fail under high pressures, the BeadScreen flowback control media cartridges feature higher burst/collapse ratings and offer improved erosion and plugging resistance to help enable long-term, sand-free production.

Because the DEEPFRAC sleeves are modular, the lower completion assembly was delivered in only seven weeks as opposed to an average of six months for conventional equipment. Using an openhole completion method eliminated casing and cementing operations and simplified fluid logistics, trimming rig days by more than a week before lower completion operations even began.

Simplified rig handling and running procedures accelerated installation and the DEEPFRAC sleeves enabled treatment of 15 stages in a single, rapid pumping operation. No service tool movement was required and treatments were delivered in under 60 hours from start to finish.

The new approach also helped maximize reservoir contact. Conventional systems with limited zone counts often result in large treatments being pumped across long vertical sections, allowing fluids to take the path of least resistance and leaving some areas of the pay zone undertreated, or even untreated. The DEEPFRAC sleeves, which are modular and can be placed as close as 13 ft (3.9 m) apart, enabled more uniform treatment delivery across more stages. And the volume of proppant pumped exceeded that of a conventional three-zone stimulation job by almost 50%.

Built-in BeadScreen filtration media eliminated surface flow tests that would have been required if a basic screen system had been used, saving an estimated two and a half more days completion time. In addition to increasing reservoir contact, the new DEEPFRAC service saved the operator an estimated 25 days of rig time and USD 40 million compared to the average time and cost for a conventional cased-hole multizone completion. The new approach also significantly simplified operational logistics and reduced HSE risks.

The operator plans to complete more deepwater wells using the new DEEPFRAC service based on the unprecedented savings and potential economic impact. As of spring 2017, Baker Hughes was the only service company that had deployed a ball-activated multistage fracturing sleeve system in an openhole deepwater application.

石油圈

石油圈