EQUALIZER RF Flow Control Device

The EQUALIZER retrofit (RF) system allows operators to install ?ow control technology— post-completion—to control unwanted ?uids or steam and return wells back to desired performance levels. Reservoir heterogeneities, breakthrough of undesired ?uids, heel-to-toe effect, hot spots, and steam production can all result in sub-economic well performance, and historically, have presented operators with the costly decision of re-completing the well or drilling a new well. With the EQUALIZER RF system, operators can install a series of EQUALIZER RF ?ow control devices (FCDs) and high-temperature (HT) REBarrier? packers inside the existing completion via tubing to equalize the in?ow of hydrocarbons. This gives operators the ?exibility to install in?ow/injection control equipment after the completion is in place, or replace existing systems to help reduce costs and maximize ultimate recovery from existing wells.

The EQUALIZER RF system can be installed inside existing slotted liner or screen completions, and the REBarrier packers compartmentalize ?ow in certain areas of the well. This helps channel production through the RF FCDs, and improves recovery along the entire length of the wellbore. The EQUALIZER RF FCD incorporates a tortuous path geometry that is built on the field-proven design used in our EQUALIZER SELECT autonomous in?ow control device.

Upon breakthrough of an undesired ?uid such as water or steam, the pressure drop across the device increases. This causes the undesired ?uid or steam to be choked back to avoid breakthrough in the lateral. The pressure drop decreases for desired ?uids.

Different ?ow resistance rating (FRR) settings can be selected for each RF device, enabling customized ?ow control options for each well. Baker Hughes Reservoir Development Services experts are available to provide technical guidance to ensure an optimal design.

The EQUALIZER RF device is compatible with our full portfolio of completions technologies, so solutions can be customized based on performance objectives.

Applications

1.Conventional or high-viscosity oil;

2.SAGD well conditions where:

– Existing completion does not provide adequate fluid production control;

– Heel-to-toe effect, reservoir heterogeneities, hot spots, or steam production inhibit optimum well performance.

Features and benefits

1.Equalization of inflow/injection:

—Ensures uniform production;

—Improves steam chamber conformance;

—Reduces effects of gas and water breakthrough;

—Improves well longevity.

2.Pressure drop is insensitive to changes in oil viscosities up to 700 cP:

—Preferentially adapts to changing fluid conditions;

—Delivers increased pressure loss to water or steam production.

3.Anti-plugging and self-cleaning design:

– Assures large unimpeded flow area;

– Minimizes erosional effects.

EQUALIZER JET Stimulation Flow Control Device

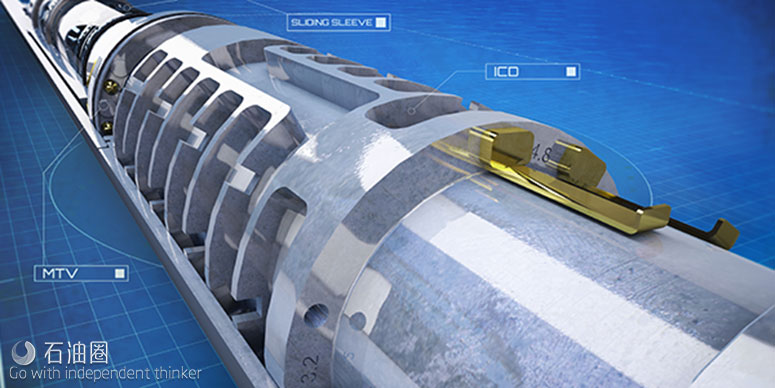

The EQUALIZER JET? stimulation ?ow control device (FCD) accelerates liner deployment and delivers precise, high-velocity acid treatments across long lateral wellbores, reducing OPEX and maximizing reservoir stimulation in carbonate formations. Using a unique multi-tasking valve (MTV) that controls communication through the string, the FCD circulates liners to bottom in 50% less time than the standard deployment method for limited-entry-liners (LEL). And high-performance jet nozzles incorporated into the MTV ensure uniform treatments—regardless of varying permeability throughout the pay zone.

Although installing LELs (liners with holes drilled in them) into wellbores is a simple way to allow acid delivery and subsequent production, getting them to bottom in extended-reach wells can be extremely challenging. Insufficient weight above the completion and friction between the pipe and the wellbore can cause liners to get stuck and fall short of total depth (TD). Circulating liners to bottom is the most reliable way to get them to TD and ensure maximum pay zone access, but enabling closed-system circulation requires an inner string and a washpipe—tools that add days of time to liner deployments.

To simplify and speed up operations, the EQUALIZER JET FCD’s MTV temporarily prevents ?ow between the tubing and the annulus, converting the liner into a solid pipe. This enables circulation around the liner during run-in, eliminating the need for an inner string and washpipe and easing deployment in long laterals. If preferred, liners can also be ?oated in using the MTV. And as long as the MTVs are in the closed position, other tubing-actuated devices like openhole packers can be set, reducing tool trips.

When the acid treatment is ready to be pumped, pressure is bled off and small pistons inside the MTVs eject, re-establishing communication between the tubing and annulus. A redundant design ensures successful actuation.

Unlike standard LELs that can have inconsistently sized and spaced holes—resulting in undertreated and even untreated areas of the wellbore—the EQUALIZER JET FCD’s jet nozzles ensure even coverage across the pay zone. The nozzles, which are precisely sized and inserted into each device, can jet acid at velocities up to 500 ft/sec for improved reservoir stimulation and production potential.

Multiple nozzle sizes are available and can be selected to match the optimal stimulation program for the reservoir. Production can ?ow directly back through the nozzle ports after stimulations are complete.

Applications

1.Liner deployment in long horizontal wells;

2.Controlled acid jetting;

3.Carbonate formations.

Features and benefits

1.Multi-tasking valve:

—Accelerates liner deployment;

—Enables circulation without the need for an inner string or washpipe;

—Eases deployment in extended reach wells;

—Maximizes reservoir contact;

—Incorporates jet nozzles for acid delivery;

—Enables actuation of other tools without additional trips;

—Features a redundant design and robust construction for increased reliability.

2.Jet nozzle inserts:

—Deliver high-velocity acid treatments;

—Ensure uniform treatment coverage across low- and high-permeability zones;

—Maximize reservoir stimulation;

—Enable long-term production inflow without risk of erosion.

石油圈

石油圈