EQUALIZER Inflow Control Devices

ICDs can help delay water/gas breakthrough and improve production in horizontal wells. But not all ICDs are created equal. Many have reliability issues and it’s driving up your OPEX. It’s also costing you production.

EQUALIZER? ICDs create the flow behavior that maximizes drainage from your specific reservoir—and they are built to last. Dependable designs deliver long-term, reliable performance so you can prolong well life and improve recovery. And you can install EQUALIZER devices 50% faster than the standard deployment approach by combining them with our patented multi-tasking valve.

Not all ICDs are created equal. Only one has over 160,000 installations with a 99% field reliability record in to back it up.

EQUALIZER HELIX Flow Control Technology

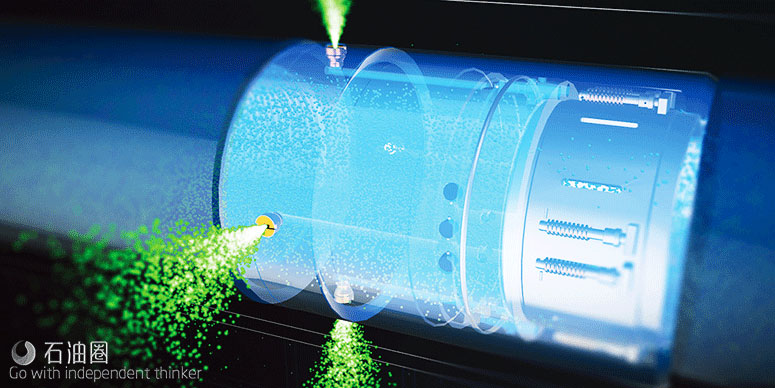

The Baker Hughes EQUALIZER HELIX? passive in?ow control device (ICD) uses a helical ?ow path to create a pressure drop across the completion, inducing consistent production along the entire lateral. This design has significant advantages over orifice or nozzle ICDs, which use ?ow constriction to generate differential pressure and can be prone to erosion and plugging.

The EQUALIZER HELIX ICD uses surface friction to create a pressure drop by directing ?ow through helical channels around the base pipe. With large ?ow area and low velocity, the EQUALIZER HELIX design is not susceptible to erosion or plugging. Its resistance rating is customized for the application to match the reservoir and completion requirements. It is especially recommended for use in high gas/oil ratio wells and gas producers, as well as water, steam, or chemical injector wells.

When combined with Baker Hughes sand control screens, the EQUALIZER HELIX ICD has been applied successfully in sandstone formations throughout the world. The EQUALIZER HELIX consolidated formation (CF) system also has a proven record in consolidated formations such as carbonates.

Baker Hughes is at the forefront of ?ow control technology. As developers of the first in?ow control device design in 1995 and creators of the first autonomous ICD in 2009, Baker Hughes has more global experience and field installations than any other company. Millions of feet of ICDs have been installed by Baker Hughes for operators around the world.

Applications

1.Producers and injectors;

2.Conventional oil and gas;

3.Sand control and non-sand control environments;

4.Highly fractured reservoirs;

5.High-rate gas wells;

6.Gas condensate wells;

7.Multilaterals;

8.Cyclic steam stimulation (SAGD wells).

Features and benefits

1.Helical channels around the base pipe use friction to provide a pressure drop:

—Delivers as-designed resistance to flow;

—Is less prone to plugging and erosion than orifice-style ICDs.

2.Equalizes production or injection from heel to toe:

—Improves oil recovery;

—Limits gas or water influx;

—Assures even injection of water, steam, or chemicals;

—Delays water production in high-rate gas wells。

3.In-house dynamic reservoir modeling:

—Ensures optimized completion design;

—Provides recommendations for optimized well productivity.

4.Durable, rugged design and construction:

—Ensures reliability (millions of feet installed worldwide).

5.Compatible with other technologies in the Baker Hughes completions portfolio:

—Can be combined for customized pay zone management solutions.

EQUALIZER SELECT Autonomous In?ow Control Device

The EQUALIZER SELECT? autonomous in?ow control device (AICD) is an innovative reservoir drainage system that uses specially designed geometry to optimize production and delay water or gas coning. The system equalizes in?ow/ out?ow along the entire length of the wellbore to ensure better recovery.

The EQUALIZER SELECT system can control ?ow under a wide range of changing reservoir conditions throughout the well’s life. It compensates without any active intervention to control unwanted ?uids while promoting hydrocarbons, making it the industry’s first commercially available AICD.

The EQUALIZER SELECT system combines viscosity insensitivity to ?uids up to 700 cP with the erosion and plugging resistance of the EQUALIZER HELIX? design. The EQUALIZER SELECT device incorporates a series of ?ow chambers, each containing a restriction. As the production ?ows through each successive chamber, pressure is reduced sequentially. Each set of ?ow slots is staggered, so ?ow must turn after passing through each chamber. This configuration minimizes jetting effects. Flow area through the slots is larger than openings in analogous orifice PICDs, so the potential for plugging and erosion is dramatically reduced.

Adjusting the resistance setting of each joint of EQUALIZER SELECT AICD creates a customized in?ow control solution for each well. The EQUALIZER SELECT AICD provides superior erosion resistance compared to nozzle or orifice ICDs, and significantly longer productive life without plugging, lower drawdown pressures, improved overall oil production, and dynamic control of unwanted ?uids.

Based on the latest data the EQUALIZER SELECT AICD is field-adjustable, so ?ow resistance can be modified at the wellsite by opening or closing ?ow paths through selected quadrants of the device.

When combined with Baker Hughes sand control screens, the EQUALIZER SELECT AICD has been applied successfully in sandstone formations throughout the world. The EQUALIZER SELECT consolidated formation CF? system also has a proven record in consolidated formations like carbonates. The EQUALIZER SELECT AICD is recommended for oil wells expected to produce multiphase ?ow and for oil-steam producers in steam-assisted gravity drainage (SAGD) well pairs.

Baker Hughes is at the forefront of ?ow control technology. Developers of the first in?ow control device (ICD) design in 1995 and creators of the first autonomous ICD in 2009, Baker Hughes has more global experience and field installations than any other company. Millions of feet of ICDs have been installed by Baker Hughes for operators around the world.

Applications

1.Conventional oil;

2.SAGD;

3.High-viscosity oil;

4.Multilaterals;

5.Conditions where;

—Heel-to-toe effect is an issue;

—Reservoir heterogeneities exist;

—Water/oil or gas/oil contacts are present in the reservoir.

Features and benefits

1.Equalization of inflow and outflow profile:

—Ensures uniform production profile;

—Improves oil recovery.

2.Delays gas and water breakthrough:

—Improves well longevity.

3.True viscosity insensitivity for fluids up to 700cP:

—Adapts to changing fluid conditions.

4.Antiplugging and self-cleaning design:

—Assures unimpeded flow.

5.Inflow area four times greater than nozzle or orifice PICD designs:

—Minimizes erosional effects;

—Prevents plugging.

6.Option for multiple adjustable fluid resistance ratings:

—Easily adjustable before deployment for operational flexibility;

—Reduced inventory requirements.

7.In-house dynamic reservoir modeling:

—Provides recommendations for optimized well productivity.

8.Compatible with other technologies in the Baker Hughes completions portfolio:

—Can be combined for customized pay zone management solutions.

石油圈

石油圈