In the current market environment, operators are looking for cost-effective ways of enhancing production from existing wells. The well intervention market seems set to expand, particularly given the impending rise in subsea P&A and decommissioning work.

In this context, oilfield equipment providers and downhole service firms are looking for ways to implement and execute new well intervention technologies and techniques. One of these methods that is gaining momentum is riserless intervention.

In December, James C. West of Evercore ISI reported on a subsea intervention overview which was held by Superior Energy Services in Houston. Aside from the overview, the presentation focused on the company’s new riserless intervention system within the technical solutions segment’s Wild Well Control (WWC) brand.

Well intervention encompasses the services performed after the initial drilling, completion, and flowback/production of a new (flowing) well. Intervention operations can take place early in the productive lifecycle of a well, and can continue through the decommissioning phase at the end of the well lifecycle. Purposes of well intervention include production management/enhancement, well integrity logging, pressure control, general remedial work, and plug and abandonment (P&A). Intervention operations are considered high-risk from a HSE perspective because of the exposure to the hazardous pressures of a “live” well.

The presentation outlined the four conventional subsea intervention methods, noting that the selection of method is based on the well’s needs, equipment available, costs, and regulation, to name just a few factors. In brief, the four intervention methods presented include:

Intervention fluids. These are fluid offerings designed for post drilling wellbore intervention and workovers, and are well-suited for the flow-assurance risks associated with deepwater intervention.

Subsea Intervention Lubricator. This involves a single-trip riserless system that facilitates access to large bore subsea wells from a monohull vessel.

Riser-based well intervention. For extended depth intervention work, or coiled tubing intervention operations, a rigid riser is needed to connect the subsea tree or wellhead to a well intervention vessel. Riser-based intervention uses a high-pressure riser to contain the pressure during a workover or intervention operation.

Intervention riser system. This method employs a marine riser with a drilling BOP and a subsea test tree to pressurize the well.

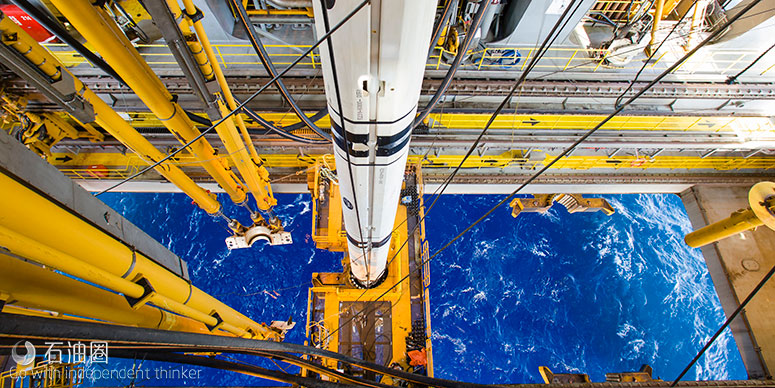

Riserless intervention is a new unconventional method being pioneered by WWC and others, West noted. Riserless intervention eliminates the need of a drilling riser connected to a BOP, allowing E&Ps to employ smaller dynamic positioned monohull vessels instead of drilling rigs. The use of a monohull vessel reduces mobilization time for life-of-well operations including wireline, logging, light perforating, zone isolation, plug setting and removal, and decommissioning.

Prior to the offshore drilling rig cyclical downturn, riserless systems were expected to reduce costs by 40-60% compared to traditional well intervention with an expensive drilling rig. The technology is based on wireline well maintenance, where the cable is routed via a subsea lubricator system into the subsea well. Traditional activities are wireline operations for well logging, perforation, and installing or pulling equipment like plugs and downhole safety valve inserts. The operational envelope can be extended by use of tractors (electrical tools used to push the toolstring into hole, overcoming wireline’s disadvantage of being gravity dependent) in horizontal wells.

Several oilfield service companies provide subsea well intervention services, with capital equipment providers, vessel operators, system operators, and service companies all playing key roles. In addition, several technology leaders have collaborated on packaged offerings, such as OneSubsea and FTO Services.

More recently, Subsea Services Alliance (a contractual collaboration between Helix Energy Solutions and Schlumberger) announced the co-development of a new riserless well intervention system that would facilitate abandonment operations in open waters.

WWC believes this offering is comparable to its BOP capping system, meanwhile, the company has already commercialized a true riserless system. The company’s first 7 Series system commenced operations this time last year and is certified to water depths of 10,000 ft and maximum working pressure of 10,000 psi. The company says that the system allows for a safe and efficient means of conducting a variety of slickline, e-line and braided line operations, including setting and pulling plugs, shifting sleeves, logging and bailing as well as wireline conveyed tractor operations such as milling and cleaning.

WWC says that the system allows for riserless plug and abandonment of subsea wells that exceeds BSEE guidelines, and Superior offers a turnkey solution for subsea plug and abandonments inclusive of ‘B’, ‘C,’ and ‘D’ annulus isolation and wellhead severance when required. During its first year of operation, WWC’s 7 series system performed nine deepwater P&A jobs in the GoM for more than 50% market share. The company says it averaged 11 days to P&A a well versus the industry standard of 30 days per well.

石油圈

石油圈