Reduce well costs with high BUR drilling while gathering critical LWD data

Operators are always looking for opportunities to reduce drilling risk, improve performance, quickly bring wells to production, and maximize hydrocarbon recovery. Rotary steerable systems (RSS) on the market today have limited abilities to provide advanced logging while drilling (LWD) services combined with high buildup rates (BUR). This limitation has forced operators to compromise between the ability to obtain LWD data or to drive efficiency with high BUR. Additionally, the need to drill slimmer holes also required a compromise in performance.

The Baker Hughes 6¾-in. AutoTrak eXact high-build RSS improves drilling efficiency by providing the high BUR that operators need to drill shorter curve sections. It is capable of drilling curves of up to 12°/100 ft (12°/30.5 m), maximizing horizontal reservoir exposures and avoiding directional work in troublesome formations. A newly introduced 4¾-in. system offers improved performance over other slimhole tools by allowing greater weight-on-bit and improved reliability, thanks to a rugged steering unit with fewer components and hybrid electronics which allow increased tolerance to dynamics and operate up to 165°C (329° F.)

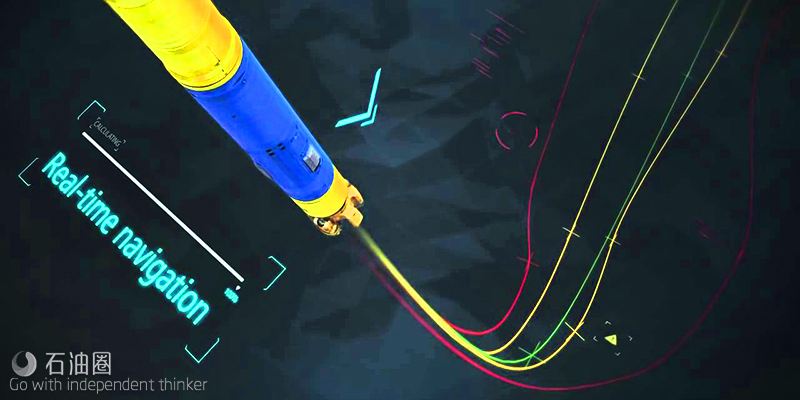

Additionally, the AutoTrak eXact system is fully compatible with the Baker Hughes suite of advanced LWD services. This enables operators to obtain accurate and comprehensive formation evaluation and reservoir data to geosteer wells to target, maximize production, and minimize the risk and cost of development. The enhanced directional capability enables quicker corrections if targets or geology change unexpectedly.

The AutoTrak eXact RSS can drill the most complex 3D profiles with superior borehole quality and directional control, thus reducing overall time on well and improving the efficiency of completion operations.

The proprietary, closed-loop steering control of the AutoTrak eXact system delivers the most precise and consistent performance in the industry. Automated steering control ensures borehole quality in all applications, even in the most challenging wells.

Baker Hughes has designed fit-for-purpose drill bits, such as the Kymer hybrid drill bit and the Talon high-efficiency drill bit, to work with the AutoTrak eXact RSS to provide better directional control, consistent reliable build rates, unsurpassed borehole quality and improved stability.

Combining the AutoTrak family’s proven precision with higher BUR capability and LWD compatibility, the AutoTrak eXact RSS offers a unique and uncompromising solution for your most challenging wells.

The AutoTrak eXact system combines highbuildup-rate capability with advanced logging-while-drilling (LWD) services, enabling optimized completions, improving drilling efficiency, and maximizing production potential. Using proprietary and proven closed-loop steering control, the AutoTrak eXact system delivers precise wellbore placement with high bore hole quality in all applications for easier casing runs. The system has the ability to drill shorter curve sections up to 12°/100 ft, compared with conventional systems that offer 5–6°/100-ft build rates. This maximizes reservoir exposure and helps avoid costly directional work in troublesome formations. Compatible with the Baker Hughes’ advanced suite of LWD services, the AutoTrak eXact system also provides access to real-time formation evaluation and reservoir data to help geosteer wells and optimize placement in the reservoir.

Applications

Conventional and unconventional

Land and offshore

Simple and complex 3D wellbore profiles

Features and benefits

Precise closed-loop steering that adjusts for direction and inclination

– Delivers exact wellbore placement

– Improves borehole quality by consistently drilling smooth curves and straight tangents

– Facilitates faster completions and enhanced production

Oriented kick-off from vertical

– Reduces risk in limited geometric and geological envelopes (limited leases, thin reservoirs)

– Saves time and footage

High BUR capability

– Reduces drilling days per well by drilling a shorter curve section

– Increases production by exposing more of the reservoir, earlier

– Avoids directional work in troublesome formations

Compatible with Baker Hughes suite of advanced LWD services

– Provides real-time formation evaluation

– Offers precise wellbore placement using Reservoir Navigation Services

Case study

Case one: AutoTrak eXact RSS and Talon Force Bit Drilled Challenging Well Profle in Congested Field

Location: UK Continental Shelf

Results

Drilled challenging well profile

Met planned maximum BUR of 6°/100 ft (30 m) and flat turn rate of 7°/100 ft (30 m)

Maintained bit cutter condition to TD

Achieved ROP of 48.7 ft/hr (14.8 m/hr) through chalk

Challenges

Drill complex well profile

–7°/100 ft (30 m) maximum turn rate

–360° turn while building from 23° to 91°

–Two ESP tangent sections

Meet requirement for drill bit to be highly steerable and stable in tangent sections

Steer in stick-slip-inducing chalk

Perform complex anti-collisionoperation

Baker Hughes solution

6¾-in. AutoTrak eXact RSS

8½-in. Talon Force high-velocity PDC drill bit

Case two: AutoTrak eXact RSS Saved 90 Hours of Rig Time on Trilateral Well

Middle East

Results

Saved 90 hours of rig time

Drilled each leg of a trilateral oil well in one run

Set a new ROP field record

Placed three high-quality wellbores

Met all formation evaluation targets

Drilled 8,300 ft of new reservoir

Avoided nonproductive time

Ran the first 4¾-in. AutoTrak eXact RSS in the field

Background and Challenges

Onshore trilateral, horizontal oil well

Reservoir with high levels of H2S

Meet a challenging well schedule

Maintain borehole quality to meet formation evaluation requirements

Baker Hughes Solution

AutoTrak eXact high-performance RSS

Genesis PDC drill bit

LithoTrak advanced LWD porosity service

石油圈

石油圈