ZoneSelect SingleShot Stimulation Sleeve

An integral part of the Weatherford ZoneSelect completion system, the SingleShot stimulation sleeve enables operators to stimulate up to 67 zones in a single run. The maximum stage count can be increased when the SingleShot sleeve is combined with other ZoneSelect sleeves.

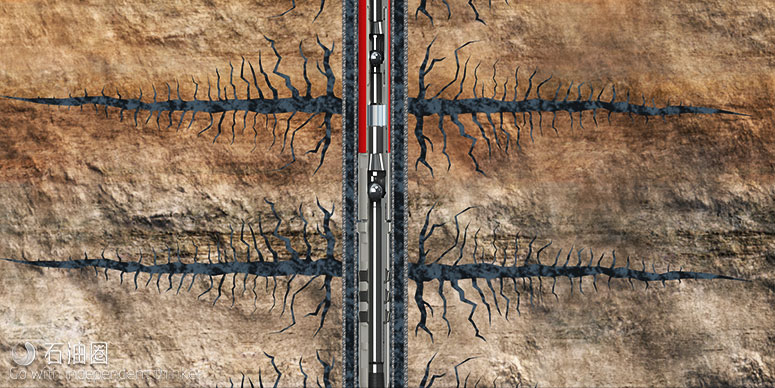

The SingleShot sleeve shifts open when a ball, which drops from the surface, lands onto an integral seat within the sleeve and applies tubing pressure. When shifted, the sleeve locks in the open position. The stimulation treatment can then be pumped into the zone. Weatherford uses engineered shear rings for accurate shifting pressure and surface indication. The continuous method of isolating below the sleeve, shifting to open ports, stimulating, and then moving to the next zone enables stimulation to be completed quickly and efficiently.

The SingleShot sleeve is designed for interchangeable ball seats. All ball seats are made from flame-hardened cast iron for efficient milling. Various Weatherford stimulation balls enhance milling efficiency or dissolve completely downhole, which eliminates milling and reduces rig time.

The Weatherford ZoneSelect? SingleShot stimulation sleeve has the unique ability to fracture up to 32 zones in a cemented application—the highest stage count of cementable graduated seat sleeves in the industry. Moreover, when used in openhole wells, the sleeve can fracture up to 60 stages. You can continuously isolate below this sleeve, shift to open ports, stimulate, and then move to the next zone for quick, efficient stimulation.

Upper and lower connections are compatible with industrystandard casing threads. Compatible Weatherford wiper darts ensure cement displacement and cleaning through the wellbore. Our proprietary shear ring enables accurate activation pressure and provides a positive indication of shear at the surface. An induction-hardened, cast-iron landing seat makes milling out fast and easy. Large flow ports maximize frac flow for effective stimulation. Snap rings lock in the open position. Upper and lower clutches allow rotational lock for efficient mill-out in both the open and closed positions. Snap-in dart nose provides robust plug bump and pressure hold.

Go even farther with the complete ZoneSelect system

1.Fracture additional stages with i-ball? sleeves actuated by a single-size ball and coiled-tubing sleeves actuated by a shifting tool.

2. Optimize isolation and removal with millable composite frac balls and dissolvable metallic frac balls

3. Achieve full pressure with time-delay toe sleeves. After pressure testing, initiate precise actuation with rupture disk toe sleeves.

By combining SingleShot sleeves with other ZoneSelect technologies, you can fracture even more stages to reach the optimum balance between production and investment.

Applications

1.Horizontal and vertical wells;

2. Multizone wells;

3.Cemented and openhole completions.

Features and Benefits

1.The SingleShot sleeve can stimulate multiple zones in a single run without thrutubing intervention, which enhances operational efficiency and reduces the time required for stimulation.

2.The sleeve insert has a mechanism to prevent the sleeve from rotating while it is open or closed, which enables efficient mill out.

3.The sleeve maximizes flow area through the ports, which reduces erosion and provides more volume for stimulation.

4.The sleeve is compatible with all ZoneSelect ball and seat systems, which helps to increase stage count and provides an optimal solution for each application.

ZoneSelect System Increases Stage Count from 32 to 50, Saves $2 Million in Completion Costs

Objectives

Maximize reservoir exposure and drainage by increasing the number of fracturing stages in an openhole 10,195-ft (3,107-m) lateral from 32 to 50 stages.

Our Approach

1.The operator could choose either an openhole completion using ball-drop-activated frac sleeves or a cemented plug-and-perf completion. The operator selected an openhole completion because of the significant cost and time savings associated with not cementing the wellbore, pumping down plugs, and milling plugs.

2.Weatherford installed 4 1/2-in. ZoneSelect SingleShot MXZ frac sleeves because they can fracture up to 59 stages in a single trip compared to the industry average of 40 stages. In this well, SingleShot sleeves increased the stage count from 32 to 50.

3. In each zone, the Metallic Hybrid (MH) Invisiball? stimulation ball shifted the ports on the frac sleeves open. After stimulation, the balls dissolved downhole to eliminate the need for milling.

4.Fraxsis* swellable packers provided reliable zonal isolation against pressures up to 8,000 psi (55.1 MPa).

Value to Client

1.Compared to a 50-stage cemented plug-and-perf completion in the same area, this 50-stage openhole completion saved approximately US $2 million—or US $40,000 per stage.

2. By increasing the stage count, the Weatherford ZoneSelect system enhanced reservoir contact.

石油圈

石油圈