Operators rely on the accuracy of cement bond logs to make critical downhole decisions. A number of factors can cause cement to be contaminated with borehole mud during the cementing process, which can decrease the density and acoustic impedance properties of the cement.

Existing evaluation techniques, which have been used for over thirty years, are acoustic-based and may not provide the accuracy needed when faced with some of today’s challenges. This new electromagnetic-acoustic technology allows operators to directly assess the integrity of cement bonds in any current wellbore environment or cement mixture.

“In our role as innovation leaders, we realize that applying yesterday’s technology to today’s challenges may not meet our customer’s emerging needs” said Mariano Gargiulo, vice president of Baker Hughes’ Wireline Services business. “This is especially true in today’s demanding environments that can test the accuracies of traditional evaluation methods. The Integrity eXplorer service provides answers that were previously unattainable.”

The Integrity eXplorer™ cement evaluation service

The Integrity eXplorer™ cement evaluation service obtains accurate measurements regardless of the type—or presence—of fluid in the wellbore, delivering greater confidence in the quality of the cement bond.

Integrity eXplorer™

Present acoustic-based technologies for cement evaluation rapidly lose resolution when cement density drops below 11 ppg. These existing technologies often interpret contaminated or lightweight cement as a partial or nonexistent bond.

Despite these challenges, operators continue to:

-Perform unnecessary remedial squeeze jobs, aiming to avoid environmental risks;

-Use these technologies to evaluate contaminated or lightweight cement, hoping the acoustic impedance of the cement slurry will fall within the reading range;

-Add wellbore fluids in air-filled boreholes so acoustic-based technologies can be used;

-Pressurize the casing and perform an additional run to detect the presence of microannuli.

In order to gain an accurate understanding of the cement bond— regardless of weight or contamination—the Baker Hughes Integrity eXplorer cement evaluation service enables operators to acquire accurate information to make critical downhole decisions with confidence.

Evaluate

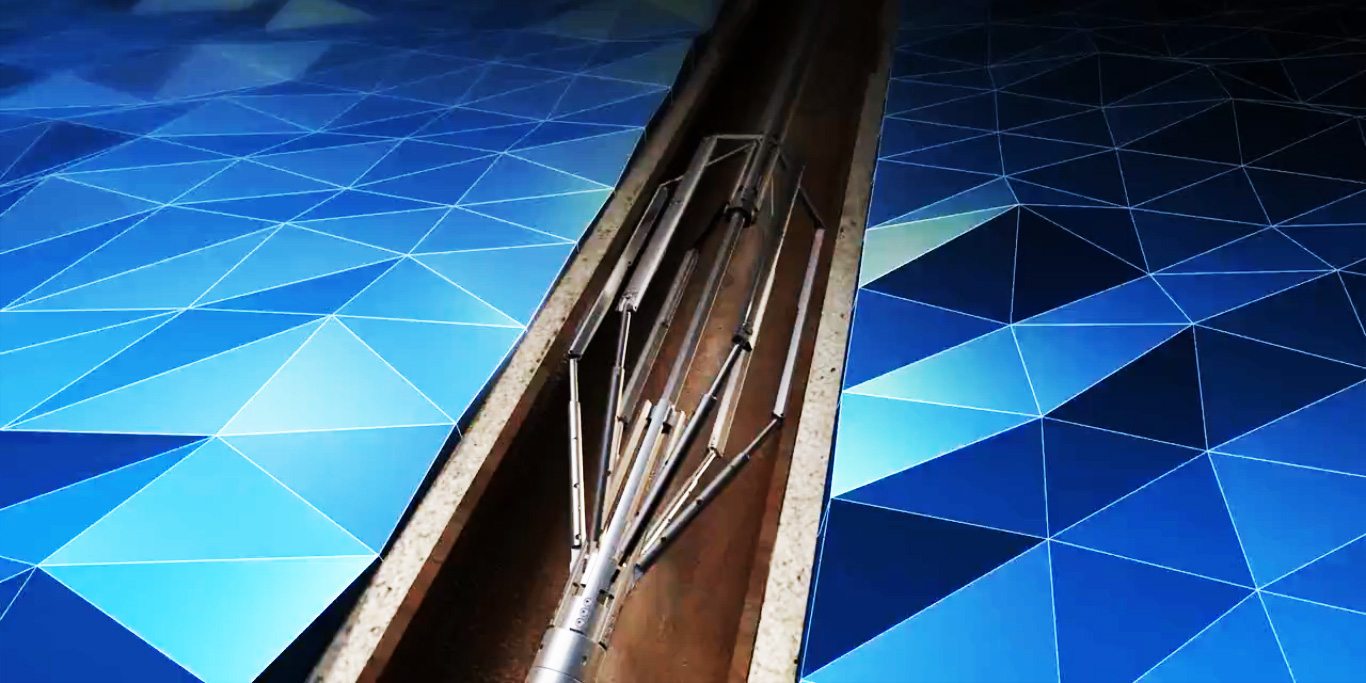

Using proprietary electromagnetic-acoustic transducer sensor technology, the Integrity eXplorer service measures the widest range of cement weights in the industry— with weights as low as 7 ppg—making it ideal for evaluating contaminated, lightweight, and foam cement slurries.

Acquire

Capable of measuring the cement bond in any wellbore fluid environment, the Integrity eXplorer service eliminates the need to unnecessarily add wellbore fluids for evaluation. By generating acoustic waves directly on the casing, the service can acquire measurements even in air-filled boreholes and gas-cut mud systems.

Detect

The Integrity eXplorer service eliminates the need for expensive and time consuming procedures to pressurize the casing for evaluating cement with suspected microannuli. In a single pass, the service can detect the presence of microannuli and the quality of cement with industry-exclusive sensor technology.

Ensure

The sensors are mounted on a pad design engineered to make it insensitive to moderate tool and/or casing decentralization—ensuring log quality is not compromised and making it ideal for demanding deployments in highly tortuous wells.

Decide

With the data provided by the Integrity eXplorer service at the rig site, operators can make faster decisions regarding long-term zonal isolation.

Applications

-Wells with contaminated, lightweight, or foam cement;

-Deepwater wells with modified cement;

-Highly tortuous wellbores;

-Gas or CO 2 storage wells.

Features and benefits

-Electromagnetic-acoustic transducer sensor technology;

-Evaluates the cement bond accurately across the widest range of cement weights in the industry;

-Provides accurate answers in heavy wellbore fluid environments;

-Evaluates the quality of the cement bond in the presence of a microannulus;

-Enables cement evaluation in air-filled boreholes;

-Ensures log quality is not compromised by moderate decentralization.

-On-site deliverables;

-Provides data at the well site for prompt decision making.

Specifications

Make up length 19 ft 11 1 /4in. (6.08 m);

Minimum casing size (OD) 4 1 /2in. (114.3 mm);

Maximum casing size (OD) 16 in. (406.4 mm);

Maximum tool diameter 3 5 /8in. (92.07 mm);

Maximum logging speed 30 ft/min (9.14 m/min);

Maximum pressure 20,000 psi (137.9 MPa);

Maximum temperature 350˚F (177°C).

Case study

Operators in the Northern U.S. store natural gas for future use in underground gas storage (UGS) wells. Evaluating the casing cement for zonal isolation in these wells has proved to be costly because of the time and resource-intensive nature of the operation.

Conventional cement evaluation services require operators to relieve stored gas pressure, kill the well, and fill the wellbore with liquid to get effective cement evaluation data. In order to minimize losses, operators wait until the well pressure is lower than the well discovery pressure, but this condition typically occurs only once a year, significantly limiting the time when cement evaluation in these wells is possible. To reduce operational cost, safety, and environmental implications, operators need the ability to log these UGS wells at any time.

To address this issue, Baker Hughes deployed the new Integrity eXplorer™ cement evaluation service in two of the gas-filled wells. The wireline logging service was run under pressure of the wellhead.

Using electromagnetic-acoustic transducer sensor technology, the Integrity eXplorer service successfully provided cement evaluation data without fluids in the borehole. Data acquired by the Integrity eXplorer service matched previous data obtained by the Baker Hughes Segmented Bond Tool™ (SBT™) service from the same well several years ago in the presence of borehole fluids. This comparison gave the operators the reassurance they needed to determine long-term zonal isolation.

Operational and remedial expenses were significantly reduced by deploying the Integrity eXplorer service, which eliminated the need to set a plug, fill up the well with fluid for cement evaluation, and then empty the well once again to restore the storage functionality.

Challenge

-Evaluate cement in the absence of borehole fluids to determine zonal isolation

Results

-Evaluated cement in gas-filled wellbore;

-Eliminated the need for additional operational and remedial services related to cement evaluation;

-Helped operator determine long-term zonal isolation;

-Saved valuable rig time.

石油圈

石油圈