WELLSITE ANALYSIS

Cuttings analysis. Attenuated total reflectance Fourier transform infrared (ATR-FTIR) spectroscopy is a common nondestructive laboratory technique that has application as a quick, non-complex, and cost-effective wellsite method for characterizing carbonate samples.

A study assessed the potential of ATR-FTIR for identifying and quantifying carbonate rock mineralogy and demonstrated it is comparable with XRD. However, ATR-FTIR requires no special sample preparation. Once equipment is available, there is no additional cost to run samples. Mineral identification and semi-quantification take less than 5 min. This compares favorably to XRD analysis, at $350 to $500 per sample The semi-quantification of mineral concentrations may allow ATR-FTIR to serve as proxy for assessing the brittleness/fracability index of unconventional reservoirs.

Continuous XRF analysis. X-ray fluorescence is an established, rapid, nondestructive analytical technique for evaluating rock samples. Nexen Energy started a program to routinely perform continuous XRF analysis of cuttings and core from its pad horizontal wells to optimize completion and fracing programs. Acquisition of the XRF dataset has been significantly more cost-effective (compared to XRD), and also resulted in a substantial increase in the understanding of reservoir properties. The dataset resides in the common data repository, and is accessed for use in a variety of geoscience and engineering applications.

Magnetic susceptibility measurements can identify lithological variations, estimate mineral content, and correlate with key petrophysical properties. These nondestructive measurements are used to characterize core 62,63 and also offer a method to rapidly characterize drill cuttings at the wellsite or laboratory.64,65

SCIENTIFIC

Weatherford Labs and Enthought participated in a study of core recovered from the central Chicxulub crater, offshore Mexico’s Yucatan peninsula. The crater is believed to be the site of the collision of an asteroid that resulted in the mass extinctions at the end of the Cretaceous period. Recovered samples were scanned, using dual-energy CT and Enthought’s virtual core software to create 3D digital representations. The software includes detection and visualization capabilities for analyzing the composition and structure of the core.

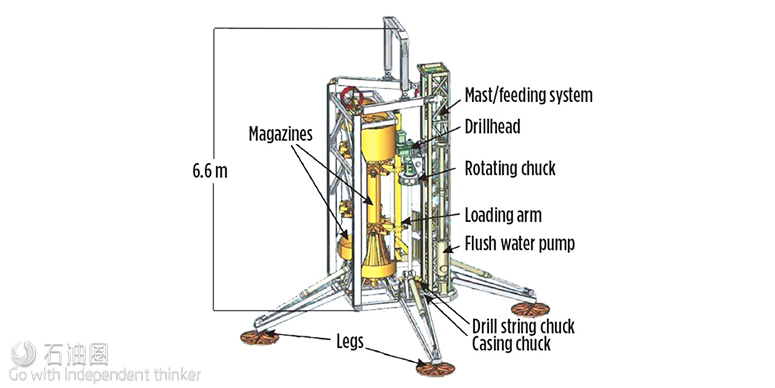

Seabed-based drilling and logging platforms. Operators are seeking ways of reducing cost related to deepwater drilling, particularly in marginal fields. Self-contained robotic systems operating directly on the seafloor offer a method for drilling shallow site-investigation boreholes, intermediate depth research boreholes, and, potentially, deeper exploration and production wells.

The MARUM-MeBo70 remotely operated seabed drilling system, developed by the Marum Center for Marine Environmental Sciences at the University of Bremen, can core and log shallow scientific boreholes. This system can operate in water depths down to 2,000 m, and can sample sediments and hard rocks down to 80 m below the seafloor. Core diameter can vary from 55 to 84 mm. Total length can exceed 70 m. The system comprises a drilling rig, winch with 2,500 m of steel-armored umbilical, control cabin, drill-tool container, workshop container, and the launch-and-recovery system. The logging-while-tripping memory probes include dual induction, magnetic susceptibility, optical imaging, acoustic, and spectral gamma ray.

Benthic’s portable, remotely operated drill can switch dynamically between piston sampling, rotary coring, and in-situ testing. Drilling is controlled by robotic actuators. Two rotary magazines hold up to 260 m of combined sampling barrels, test tools, rods and casing, enabling penetration depths in excess of 130 m, sub-seabed. Core length is 2.75 m/barrel, and piston and rotary core diameters range from 44 to 75 mm, depending on the system used. The system also can do simple methane gas analysis. Systems are available for water depths down to 3,000 m. The Badger Explorer, a robotic seafloor drilling/logging system for drilling deep boreholes and appraising and monitoring them, is still in development.”

石油圈

石油圈