想知道近几年的测井、储层评价技术新进展?看这里就对了。

来自 | World Oil

编译 | 周诗雨 郑斯赫

2017年石油价格似乎有望反弹。2016年年底之后,油气行业大约裁掉了44万个岗位,而现在各家公司又重新启动了招聘程序。过去几年,测井、岩石物理学、岩心分析和非常规油气藏储层评价领域涌现出了大量有价值的文章。此外,孔隙尺度成像技术方面也有重要的综述发表,这些文章主要探讨了页岩完井模型中使用的脆性指数的多样性。

随钻测井

井眼定位。井眼定位入门(Primer on Wellbore Positioning)是高地和群岛大学(University of the Highlands & Islands)出版的一本电子书。目前可免费从他们的网站上下载。

测距系统。哈里伯顿研发了一种新型的磁测定井方法,表面激发设备不需要进入目标井眼,只需要将表面激发设备连接到目标井的井口,并沿目标井套管传输电流信号即可。在钻邻井中的阵列梯度计会接收到相应的磁场,并计算出两口井之间的相对距离和方向。该系统主要是为SAGD设计的,无需在目标井中部署电缆测井工具。这套系统同样也适用于救援井和井眼定位。与现有系统相比,该新型系统减少了设备运输量,无需部署测井工具,同时也能降低油公司的成本和风险,减少作业人员数量。

连续测斜技术。卡尔加里大学的研究人员推出了一款低成本的捷联式惯性系统(SINS)。在不中断钻进的前提下,通过3个正交MEMS加速度计和3个正交MEMS陀螺仪,SINS能够获取整个井眼轨迹的测斜数据。而传统工具只能利用磁力计和陀螺仪获取多个静止测斜点(彼此间隔30米)的测斜数据。SINS不需要使用无磁钻铤,且由于MEMS传感器的尺寸很小,所以SINS可以在小井眼中使用。此外,该领域还有一项先进的处理技术,该技术可以利用连续的D&I(方位和井斜)测量数据来获取井眼测斜数据,该技术的测量间距为3米。

测斜精度。最近出现了几种可提高测斜精度的新模型。科罗拉多矿业学院发表了一篇相关文章,文章中的改进3D样条曲线模型可利用最高三阶的连续导数计算整个井眼轨迹。改进模型可以更精准地定位井眼、估计井眼弯曲度以及测量井眼不规则度。

新型井下定向测斜技术。传统的定向测斜装置在接单根时,利用泥浆泵重启作业进行定向测斜并将数据发回地面。Schlumberger则给出了另一种方法:中断钻杆旋转(而不是停泥浆泵)进行测斜作业,这种方法在接单根前就可以完成测斜工作。接单根工作完成后,钻柱不必保持静止。这种测斜方法无须重启泥浆泵即可完成测斜,能够保证流量恒定(井底压力不变),减小了波动和抽汲效应,降低了井眼不稳定和卡钻的风险,缩短了总测斜时间,适合MPD(控压钻井)、UBD(欠平衡钻井)和空气钻井。

双遥测随钻测井技术(MWD)。NOV井眼技术部门推出了一款可回收双遥测随钻测井工具——Black Star II。该工具能同时实现电磁数据传输(EM)和泥浆脉冲数据传输(MP),如图1所示。通过下行传输的电磁或转速信号,即可将Black StarII的传输模式从电磁模式切换到泥浆脉冲模式,不需要起下钻更换设备。模块化的设计可以实现工具组合的灵活配置,最大限度地提高作业能力。工具中整合了特制的转换模块,在系统中用现成的标准泥浆脉冲发生器即可。该系统还具有全套的MWD传感器,包括定向传感器、伽玛传感器、内压和环压传感器、轴向和径向振动传感器、ROM和温度传感器。

图1 具有EM和MP数据传输能力的可回收双遥测MWD

耐高温系统。哈里伯顿推出了一项耐高温MWD/LWD服务(Quasar Pulse/QuasarTrio),这项服务可在200℃、172MPa的恶劣环境下进行全面的三组合测井作业。基本的MWD服务可测定向、伽马、随钻压力和振动数据,能够精确定位高温高压层位的井眼。LWD服务可获取电阻率、密度和中子孔隙度数据。电阻率测试仪具有三个T-R间隔,可在不同的测量深度内获取12个电阻率测量值。密度测量工具采用了常规的Ce-137源和双向探测器,电子器件和软件的稳定性都得到了改进,可在各类作业环境温度中实现稳定测量。中子孔隙度工具采用的是常规配置,采用了镅-铍核源和一对He-3探测器组。该工具有4-3/4英寸和6-3/4英寸两种规格可选,适用孔径范围可达9-7/8英寸级别。

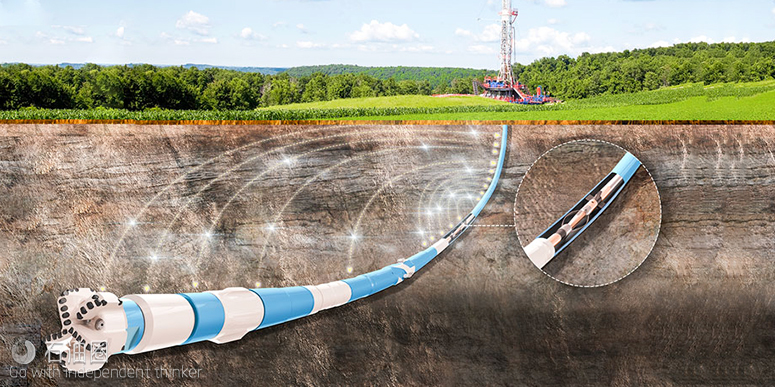

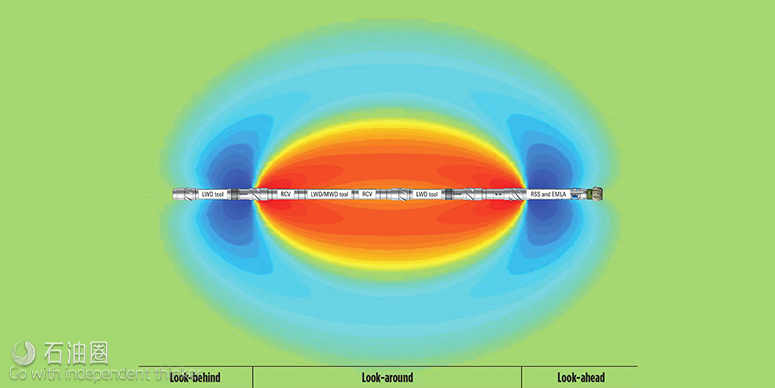

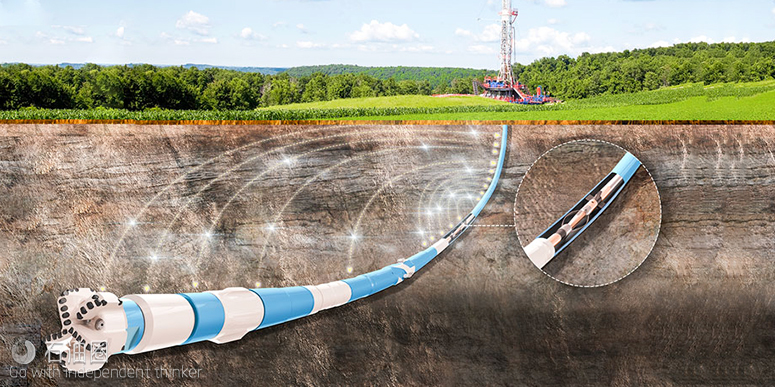

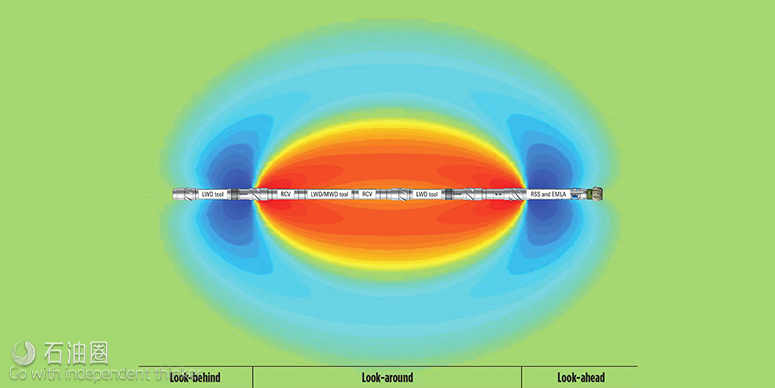

电磁测井。斯伦贝谢研究出了一种电磁前瞻性探测(EMLA)工具雏型,如图2所示。该工具与随钻成像工具(GeoSphere)中所使用的超深“环视”定向电阻率商业工具类似,采用了相同的传感器技术以及相同的多间距和多频率。EMLA采用了模块化设计,含有一个低频发射器(嵌入在钻头后1.8米处的RSS中)。钻柱中设有2~3个三轴接收器,可根据不同的应用进行灵活配置。

在直井和低角度井中,这种配置可以检测出钻头前几十米任意角度处电阻率的变化。距钻头3米处,该工具可进行补偿电阻率测量,获取解释反演中所需的浅电阻率测量数据。前瞻性探测能力能够实现主动的地质停钻,在钻遇易破裂点前选定下套管深度,或优化目标储层中的取芯点,降低钻探风险。雏型工具专为12-1/2英寸~14英寸井眼设计。迄今为止,该工具主要应用于储层段上方井段的钻进,由于这套工具更靠近储层,因此可以避免在储层上方页岩层中钻进时出现复杂情况。

图2 电磁前瞻性探测工具

声波测井。在完井设计优化中,认识页岩的各向异性至关重要。然而,由于传输问题和频散校正的不准确性,在水平井中,电缆偶极子声波测井仪测量页岩声学各向异性时可能存在不少困难。相比之下,测量高速地层中的剪切波的方位各向异性时,单极子测井仪更为有效,因为发射器和接收器都朝向相同的方向,并且可以直接测量压缩波和剪切波的折射头波,不需要进行频散校正或反演。

斯伦贝谢的导向单极子声波测量服务(SonicPacer)的对称阵列由2个发射器和4个接收器组成,T-R间隔为4英尺,接收器间距为1英尺。钨块阵列位于每个发射器和接收器的中间,能够减弱钻铤波信号。该工具配有一个分辨率高、聚焦性能好的脉冲回波换能器,可测量超声波间波和振幅,适用于井眼高分辨率成像。

为实现快速决策,纵波和横波的慢度数据既可在井下计算,也可实时返回地面计算。原始声波波形存储在存储器中,在地面处理生成各向异性应力的分布图,然后用于优化压裂作业。该工具适用于外径为4-3/4英寸和6-3/4英寸的钻铤。适用范围:1)非常规油气藏完井优化;2)利用地质结构、井眼形态以及裂缝识别和表征的声波图像布设水平井。

大井眼测井工具。哈里伯顿公司推出了9-1/4英寸版的岩石密度测井工具(Azimuthal Lithodensity),主要针对大井眼(可达17-1/2英寸)设计。该大尺寸型工具与小尺寸版本的功能一致,可进行方位密度、光电和声波间隔测量。

斯伦贝谢公司推出了一款8-1/4英寸版本的LWD NMR工具(proVision Plus),适用于直径在10-1/4英寸~12-5/8英寸的井眼。该大尺寸工具的测量直径为17英寸,适用于流速高达1,200加仑/分钟的泥浆。

井眼成像。在复杂的水平段和储层段,由于逆乳化油基钻井液能够获得更高的产能,降低作业风险,因此油基钻井液比水基钻井液更受欢迎。尽管已研发出专用于油基钻井液的电缆电阻率成像设备,但目前,LWD电阻率成像系统一般只能用于导电泥浆。为了成功应用低频、高清晰度LWD电阻率成像工具,贝克休斯正在测试一套导电油基钻井液体系。逆乳化钻井液能够在不牺牲油基钻井液性能的前提下,实现实时、高分辨率电阻率成像。

随钻取样。随钻取样最重要的是认真评价井下流体性质和流体污染情况。在没有岩芯样本的区域内进行流体扫描,是评价层内未污染流体性质唯一可靠的方法。污染评价和实时流体特性评价能够预测被污染流体的性质。斯伦贝谢对比现场随钻取样样品的井下“实地”流体性质估计值与实验室的岩芯PVT分析数据,发现较为吻合,未污染流体性质预测也得到了相同的结论。

此外,为简化随钻取样的解释流程,贝克休斯开发了一种先进的流体性质识别算法。该算法囊括了现场解释指南、泥浆的折射率、压缩性、密度和声速等信息,可以独立对每种流体成分进行传感器数据分析,并根据测量系统的可靠性和精度对传感器读数进行加权计算。该算法还具有实时显示功能,能够更轻松地识别泵入的流体类型,简化泵出过程中的方案决策流程。

The price of oil appears ready to rebound in 2017, and companies are beginning to look into hiring, after the industry shed roughly 440,000 jobs through the end of 2016. There have been a number of valuable texts have been published in the past few years on logging, petrophysics, core analysis, and formation evaluation of unconventional reservoirs. Also, major review papers on pore-scale imaging techniques, and discussing the variety of brittleness indexes used in shale completion modeling, were also published.

LOGGING WHILE DRILLING

Wellbore position. Primer on Wellbore Positioning is an ebook published by the University of the Highlands & Islands (UK). It is freely available on their website.

Ranging system. Halliburton introduced a new magnetic-ranging well-positioning method that does not require access to the target wellbore for the surface excitation. Instead, the surface excitation is connected to the wellhead of the target well, and it transmits a current signal along the cased-hole target well. The array gradiometer in the nearby drilling well receives the corresponding magnetic fields, and calculates the relative distance and direction between the two wells. This system, which was designed primarily for SAGD applications, eliminates the need for a wireline ranging tool deployment in the target well. It also has application in wellbore intersection and well positioning applications. Compared to existing systems, this one improves equipment logistics and eliminates the wireline ranging tool deployment, while reducing the cost and risk to the operator and the number of personnel needed to deliver the service.

Continuous surveying. Researchers at the University of Calgary have proposed a low-cost strapdown inertial system (SINS), using three orthogonal MEMS accelerometers and three orthogonal MEMS gyroscopes to provide survey data along an entire well trajectory, without interrupting drilling. Conventional magnetometer- and gyroscope-based systems provide survey data at stationary surveying stations (30-m intervals). This type of system could eliminate the need for non-magnetic collars, and the small size of the MEMS sensors would allow its use in small-diameter wellbores. In a separate development, an advanced processing technique uses continuous D&I measurements to provide wellbore survey data at 3-m intervals.

Survey accuracy. Several new models have been proposed for improving survey accuracy. The Colorado School of Mines, 3D advanced spline-curve model calculates the well trajectory, using continuous derivatives up to the third order, along the entire well path. The improved model allows more accurate wellbore positioning, more realistic estimates of borehole tortuosity, and a measurement of borehole rugosity.

Initiating downhole directional surveys. Conventional directional survey devices use recycling of the mud pumps during pipe connections to trigger the directional survey and send the data to surface. Another method, described by Schlumberger, uses cessation of pipe rotation, rather than cessation of the mud pumps, to trigger a survey. Surveys taken using this approach can be made prior to the pipe connection. Following the connection, the drillstring does not have to remain stationary. This approach eliminates the need to recycle to pumps to take surveys, and enables surveying with a full, unchanged flowrate (constant BHP), which minimizes surge and swab effects, thereby reducing risks of borehole instability and stuck pipe. The surveying method reduces overall surveying time and has benefits in MPD, UBD, and air drilling.

Dual-telemetry MWD. NOV Wellbore Technologies introduced a retrievable dual-telemetry MWD tool (BlackStar II) that combines the capabilities of electromagnetic (EM) and mud-pulse (MP) data transmission, Fig 1. With the BlackStar II retrievable MWD, switching from EM to MP transmission can be performed via EM or RPM downlinking to avoid costly trips to change out equipment. The modular design allows flexibility in configuring the toolstring to maximize operational capabilities. By incorporating a special translation module, a standard off-the-shelf mud pulser can be run with this system without modifications. The new system offers a full suite of MWD sensors, including directional, gamma, internal and annular pressure, axial and radial vibration, ROM and temperature.

High-temperature systems. Halliburton introduced a high-temperature MWD/LWD service (Quasar Pulse/QuasarTrio) that offers full triple-combo logging capability in hostile environments up to 392℉, and pressures to 25,000 psi. The basic MWD service delivers directional, gamma ray, pressure-while-drilling and vibration data for precise wellbore placement in HTHP zones. The LWD service delivers resistivity, density, and neutron porosity. The resistivity tool has three T-R spacings, and provides 12 resistivity measurements over a range of investigation depths. The density tool uses a conventional Ce-137 source and dual detectors, and has improved stabilization electronics and software to provide a stable measurement over the full temperature operating range. The neutron-porosity tool is a conventional configuration, with an americium-beryllium nuclear source and a pair of He-3 detector banks. The service is available in 4¾-in. and 6¾-in. for boreholes up to 97/8-in.

EM logging. Schlumberger introduced prototypes of its new electromagnetic look-ahead (EMLA) tool. It uses the same sensor technology, and operates with the same multispacing and multifrequency measurements, as the commercial ultradeep “look-around” directional resistivity tool used in the mapping-while-drilling service (GeoSphere). EMLA is modular and consists of a low-frequency transmitter inserted in the RSS, 1.8 m behind the bit. It has 2–3 triaxial receivers in the drillstring, offering a flexible configuration for different applications.

This configuration can detect changes in resistivity, tens of meters ahead of the bit, at all incidence angles in vertical and low-angle wells. A compensated resistivity measurement is made 3 m from the bit, to provide a shallow resistivity measurement used in the interpretation inversion. Look-ahead capability can reduce drilling risk by allowing proactive geo-stopping, to establish casing points above a drilling hazard, or to optimize coring points in a target reservoir. Prototypes have been designed for 12½-in. to 14-in. boreholes. The tool’s primary application, to date, has been to drill the well section above the reservoir, closer to the top of the reservoir to avoid complications in the shale above the reservoir.

Acoustic logging. Knowledge of shale anisotropy is critical for optimizing completion design. However, measuring shale acoustic anisotropy in horizontal wells, using wireline dipole tools, can be difficult, due to conveyance problems and inaccuracies in the required dispersion corrections. By contrast, a unipole tool configuration is more efficient at measuring azimuthal shear anisotropy in fast formations, because the transmitters and receivers are oriented in the same direction, and directly measure refracted head waves from the component compressional and shear measurements; no dispersion correction or inversion is required.

Schlumberger’s oriented, unipole sonic measurement service (SonicPacer) has a symmetric array of two transmitters and four receivers, with a T-R spacing of 4 ft and an inter-receiver spacing of 1 ft; an array of tungsten slugs between each transmitter and receiver attenuates the tool collar-mode signal. The tool has a high-resolution, focused, pulse-echo transducer to generate ultrasonic standoff and amplitude measurements that can be used to make a high-resolution image of the borehole.

Compressional and shear slowness results can be calculated downhole and sent uphole in real-time for rapid decisions. The raw sonic waveforms are stored in memory and can be processed, on surface, to produce an anisotropic stress profile to optimize fracturing operations. The tool is available in 4¾-in. and 6¾-in. collar sizes. Applications include: 1) completion optimization for unconventional reservoirs; and 2) assessment of horizontal well placement, using sonic images of geologic structures, borehole shape, and fracture identification and characterization.

Large-hole tools. Halliburton introduced a 9¼-in. version of its lithodensity tool (Azimuthal Litho density) for use in boreholes with up to a 17½-in. diameter. The larger tool provides the same functionality as its smaller counterparts, including azimuthal density and photoelectric and acoustic standoff measurements.

Schlumberger introduced an 8¼-in. version of its LWD NMR tool (proVision Plus) for use in boreholes between 10¼-in. and 12 5/8-in. The larger tool has a 17-in. diameter of investigation and can accommodate mud flowrates up to 1,200 gal/min.

Borehole imaging. In complex lateral and reservoir sections, the use of invert emulsion OBM is preferred over WBM, due to the higher performance provided by OBM and its ability to reduce operational risks. Although wireline resistivity imaging devices have been developed for specific use in OBM, LWD resistivity imaging tools are designed for use in conductive mud systems. Baker Hughes is testing an electrically conductive OBM system that supports the deployment of low-frequency, high-definition LWD resistivity imaging tools. The invert emulsion drilling fluid allows real-time, high-resolution resistivity imaging without sacrificing the performance of an OBM.

Sampling-while-drilling. When sampling-while-drilling, it is essential that downhole estimates of fluid properties and fluid contamination are reliable, as these may be the only available estimates of clean-fluid properties in zones where fluid scanning was performed with no physical sample recovery. The contamination estimates, together with the real-time fluid property estimates, enable prediction of the uncontaminated fluid properties. Schlumberger compared downhole “field” estimates of fluid properties from sampling-while-drilling operations with laboratory PVT analyses made on the recovered samples and found good agreement, as did comparison of downhole-predicted clean-fluid properties with laboratory-cleaned estimates.

In another development, Baker Hughes developed an advanced fluid-typing algorithm to simplify the interpretation of the cleanup process during sampling-while-drilling operations. The algorithm incorporates interpretation guidelines from field applications and includes information about the mud type from measurements of refractive index, compressibility, density, and sound speed. An independent analysis of the sensor data is performed for each fluid component, and the sensor readings are weighted, using the reliability and accuracy of the measurement system. Real-time display enables easier identification of the fluid type pumped and simplifies decision-making during the pump-out process.

未经允许,不得转载本站任何文章:

-

- 白矾

-

石油圈认证作者

- 毕业于中国石油大学(华东),油气井工程硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。

石油圈

石油圈