The ability to predict the effect of faults on locating remaining hydrocarbon is critical to optimal well-placement, reservoir-management, and field development decisions. The tool sand techniques available for realistic differentiation between sealing and nonsealing faults have presented a great challenge to the industry. This paper discusses the results of an integrated study that incorporated detailed geology and reservoir engineering to understand production behavior of a complexly faulted high-pressure/high-temperature field in the North Sea.

Introduction

Predicting fault-seal breakdown is a challenging task because it involves many interrelated factors and complex relationships. Knowledge of these factors is both nonunique and subjective. Most faulting processes have been studied in isolation, and the relationships among many of the processes are understood poorly.

Reservoir depletion can, in principle, induce stress paths capable of reactivating intra reservoir faults and, hence, potentially cause breakdown of their sealing integrity. Fault-seal breakdown may also be invoked falsely where oil/water contacts change across a fault(i.e., the fault is a capillary seal) but the fault does not compartmentalize pressures in production. This apparent seal failure can arise because of pressure communication in the water leg below the oil column. It is not clear why pressure depletion should cause capillary seal failure. However, publications exist that attempt to attribute production behavior observed in fields to fault-seal breakdown in a production realm, because of pressure depletion on one side of a fault.

The first attempts to incorporate geologically reasonable fault properties into production-simulation models involved the calculation of transmissibility multiplier on the basis of absolute permeability and thickness of fault rocks. These calculations do not capture the multiphase behaviors of fault rocks. A key problem with this approach is that a huge number of pseudofunctions needs to be calculated to take into account the large variation in fault properties (e.g., thickness, absolute permeability) and flow rates and whether the fault is going through drainage or imbibition during production. The second attempt involved calculating transmissibility multipliers (also known as seal factors) on the basis of fault permeability. The key problem with this approach is that fault permeability depends on shale gouge ratio and fault displacement alone. The calculation does not capture the impact of reservoir permeability on fault permeability.

There is a greater consensus as to how faulted-rock properties should be modeled in production-simulation studies, largely because the controlling properties are inherently more predictable (sealing capacity of faults is controlled by the weakest point). A review of methods for calculating fault properties inflow-simulation models concluded that the most important aspect is ensuring that the correct juxtapositions are contained in the model and that geologically reasonable fault-permeability and-thickness values are used to calculate transmissibility multipliers.

Field Overview

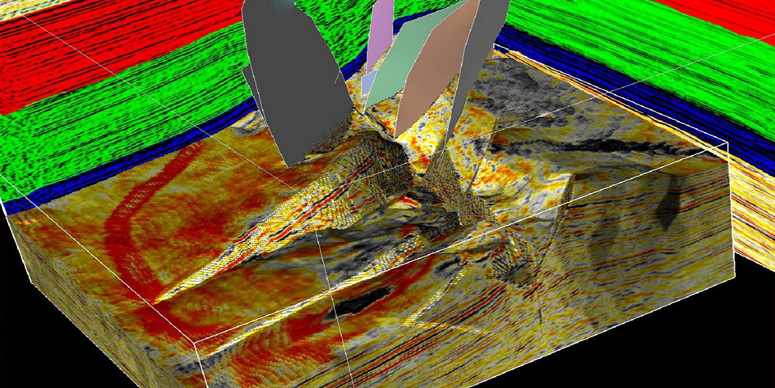

The Egret field, 150 miles east of Aberdeen in 90 m of water, is fault bounded on three sides and dip closed to the east (Fig. 1). The fault architecture divides the field into five lateral compartments. Oilbearing Pentland and Skagerrak are key producing reservoirs of interest; Skagerrak reservoir, with an average reservoir permeability of 50 md, is the focus of the current dynamic fault-seal analysis. Laterally extensive flood-basin shales separate different flow units of the Skagerrak formation and are likely sources of vertical compartmentalization. Production started in 1998. In 1999, a flattening of the pressure, which extended to 2006, was observed. From material-balance work, flattening of pressure was not expected until below bubble point if there were no change in connected stock-tank oil initially in place (STOIIP). Therefore, the hypothesis is that observed pressure flattening could be a result of cross-fault flow that changed the connected dynamic STOIIP as a result of drawdown during production.

As a result of this production behavior, fault transmissibility from lateral connectivity between compartment sand changes with depletion were recognized as key subsurface uncertainties.

This paper discusses the results of an integrated study that incorporates detailed geology and reservoir engineering to understand production behavior of a complexly faulted field where fault-seal factors change dynamically. The three main techniques used are the proprietary Petrel Fault Transmissibility Multiplier (FTM) plug-in tool, production analysis, and deconvolution.

Proprietary Petrel FTM Plug-In

Fault properties were generated from the Shell FTM tool. The results were analyzed to understand the likely effects on cross-fault fluid flow. The algorithm is underpinned with geology and reservoir properties and is deployed as a plug-in. It automatically calculates fault seal factors for all grid-cell connections using structural model and reservoir properties that already exist in the static reservoir model. Compartmentalization and production behavior observed in Egret field provided an opportunity to apply the plug-in and investigate dynamic fault-seal breakdown across one of the faults during production at a drawdown of approximately 6,000 psi. From the location of the producer well, the key fault that could break down and affect production is most likely the fault separating Compartment A and the northern block.

Production Analysis

The objectives of performing production analysis were to estimate connected oil volume during a rapid pressure depletion phase and verify influx of fluid and pressure support from another compartment into the producing block. The numerical interpretation method was used. Results were achieved by changing the fault transmissibility multiplier on the fault until a satisfactory match on historical production data is obtained.

The pressure-depletion profile shows that fault-seal breakdown occurred before the perforation of the Pentland formation; hence, production analysis was restricted to the Skagerrak historical production data.

Deconvolution

A.C. Gringarten’s 2010 paper “Practical Use of Well-Test Deconvolution” (Paper SPE 134534) showed how deconvolution can be used to identify compartmentalization and pressure recharge from other layers, which is difficult to observe from conventional analysis. A similar approach was applied in this work. The objectives here were to identify the fault where the fault seal had failed over the production time scale and estimate the distance traveled by the pressure transient after fault-seal breakdown. An attempt was made to predict the origin of fault-seal failure on the basis of distance obtained. The analysis was also restricted to the Skagerrak historical production data because that was the period during which fault-seal breakdown was suspected to have occurred.

Results and Discussion

This paper presents three main methods used to identify dynamic fault-seal breakdown. The first involves the use of Shell’s proprietary FTM plug-in, while the other two use well-test analyses.

In the first approach, the dynamic fault-seal breakdown observed would have been difficult to resolve without the use of the FTM plug-in to assign varying geologically and petrophysically realistic fault properties along the fault. Calculated Egret fault permeabilities were cross plotted against mercury/air capillary-entry pressures from a global proprietary database, which showed that an entry pressure of 6,000 psi needs to be exceeded to allow flow across the fault.

The second fault-seal breakdown investigation technique on Skagerrak historical production data was performed with production-analysis software, which identified the leaky boundaries. History matching was achieved with low values of fault transmissibility multiplier. These low values suggest that the reservoir cannot be drained by a single producer.

The third technique used was deconvolution. Deconvolution not only identified the transmissible fault but also identified the region where dynamic fault-seal breakdown might have started. This was evident from the distance traveled by the pressure transient during the transition period.

Results obtained from production analyses, deconvolution, and the proprietary FTM plug-in indicate the likely faults where fault-seal breakdown could have occurred. The results areal so consistent with 2005 4D-seismicdata interpretation.

石油圈

石油圈