从套管完井转向裸眼完井,级数增加,封隔器的强度和应用能力提升。

来自 | Packers Plus等

编译 | 白小明

阅读“封隔器技术新进展(二)”请点击。

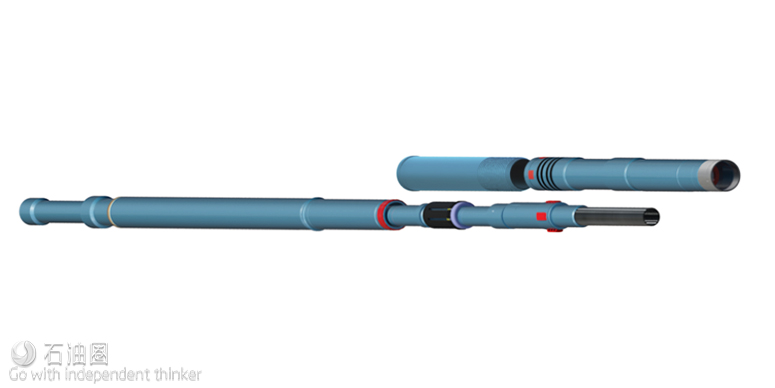

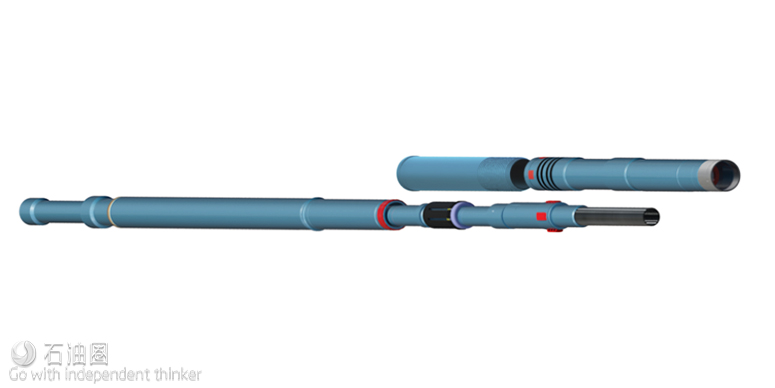

Packers Plus公司还推出了一种新的应用于水平井的尾管悬挂封隔器,水平井需要将设备推送入井内,封隔器要承受压缩力。Themig表示,为确保完井系统的下入和坐封准确性,新设计配备了防止提前坐封的机构,因此生产封隔器具有高压密封能力。

TIW(TIW是一家为油气行业提供定制化钻井和完井设备的供应商)技术支持和培训总监Terry Howard表示,尾管悬挂封隔器通常作为尾管串的一部分,永久下入到套管井内。目前,为实现更好的井筒完整性和成本效益,应用的越来越广泛。他称,“回到20世纪80年代,尾管顶部封隔器在尾管中的使用率大约在20%左右。而如今,这一数字达到了80~90%。”

在许多情况下,为了避免在后续固井质量较差的情况下补下一个封隔器,与尾管一同下入一个封隔器已经成为了作业公司的标配。Howard表示,“在过去,作业公司一般在下入尾管时不带封隔器。然而,如果固井后,尾管顶部测试结果不理想,他们不得不暂停作业,补下封隔器,这样就增加了额外的钻机时间,需要起下钻多趟。因此,从总成本和长远角度考虑,封隔器和尾管一起下入可以节约不少成本。”

井越来越深,压力和温度越来越高,推动了封隔器强度和能力的提高,Howard指出,“30年前,能够承受5,000psi压差的尾管顶部封隔器可以算是业内数一数二的产品了。而在今天,我们已经拥有了10,000psi压差级别的产品,且正在向15,000psi压差级别努力。”

Howard继续说道,全球客户都在使用TIW的尾管悬挂封隔器,但深水是一个重要市场,作业者认为额外的密封非常重要。“作业者希望尾管顶部封隔器更加结实,能够在更高的温度下能够承受更大的压力。目前,封隔器的温度上限通常为204℃左右,但目前有的作业温度已经到了232℃,而且一些作业者预测个别环境的温度甚至会达到260℃。”

为了克服弹性材料在高温下的局限性,TIW开发了一种可膨胀的尾管悬挂封隔器,即XPak,它可以在悬挂器坐封的套管和尾管悬挂器之间形成金属-金属密封。利用液压工具激活,然后膨胀,施加较大的压力使钢管延伸接触外部的套管。Howard解释道,“该封隔器的坐封方法与固体膨胀技术类似,但它提供的密封更加可靠,维持的压力更高,而且可以用于比常规橡胶压缩坐封封隔器更高的温度环境,是极端环境下的理想选择。”封隔器内的弹性材料能够形成第二道密封。

Liner Hanger Packers

Packers Plus is also introducing a new liner hanger packer for the compression forces required in horizontal wells where equipment needs to be pushed into the well. Configured with an anti-preset mechanism, the new design will ensure the completion system is fully installed and provide the high-pressure sealing capability of a production packer, Mr Themig noted.

Liner hanger packers, installed permanently in the well as part of the liner hanger assembly commonly used in cased holes, are increasingly being used to achieve greater well integrity and for cost efficiency, according to Terry Howard, Director of Technical Support and Training for TIW, a provider of custom-engineered drilling and completions equipment for the oil and gas industry. “Back in the 1980s, liner-top packers were run on about 20% of liners installed in wells,” he said. “Today, they are used 80% to 90% of the time.”

In many cases, operators are running the packer as standard equipment with the liner to avoid having to install one later in case of a poor cement job. “In the past, operators chose not to run the packer with the liner. However, if the top of the liner did not test well after the cement was pumped, they had to suspend operations and go back in with the packer, which involves extra days and rig time and more trips in and out of the hole,” Mr Howard said. “It comes down to overall cost, and being preemptive saves money in the long run.”

Deeper wells and higher pressures and temperatures have been drivers for improving the strength and capabilities of liner hanger packers. “Thirty years ago, a liner-top packer that would hold 5,000 differential strength was considered top of the line,” he noted. “Today, we’re at 10,000 psi and looking to go to 15,000 psi.”

TIW’s liner hanger packers are used globally, but deepwater is a key market as customers see the importance of having the additional seal, he continued. “Customers also want liner-top packers to be more robust in terms of how much pressure they will hold at increasingly higher temperatures,” Mr Howard said. “The temperature ceiling is typically around 400°F, but we have seen environments as high as 450°F, and some operators are predicting 500°F.”

To overcome the limitations of elastomers in high temperatures, TIW has developed an expandable liner hanger packer, the XPak, which creates a metal-to-metal seal between the liner hanger and the casing where the packer is being set. Expansion is provided with a hydraulic tool that exerts a tremendous amount of force and stretches the steel tube until it contacts the outer casing. “The packer is similar to solid expandable technology in the setting method, but it provides a much more reliable seal, holds higher pressures and can operate in higher temperatures than conventional rubber compression-set packers,” he explained. “It is ideal for extreme environments.” An elastomer installed in the packer serves a secondary seal.

未经允许,不得转载本站任何文章:

-

- 白矾

-

石油圈认证作者

- 毕业于中国石油大学(华东),油气井工程硕士,长期聚焦国内外石油行业前沿技术装备信息,具有数十万字技术文献翻译经验。

石油圈

石油圈