The AxeBlade* ridged diamond element bit positions Axe* elements along the bit face to achieve increased ROP and steerability in a wide range of applications through increased cutting efficiency and superior impact resistance.

The new-generation 3D cutter geometry of the Axe ridged diamond element combines the shearing action of a conventional PDC cutter with the crushing action of a tungsten carbide insert (TCI).

Increased cutting efficiency

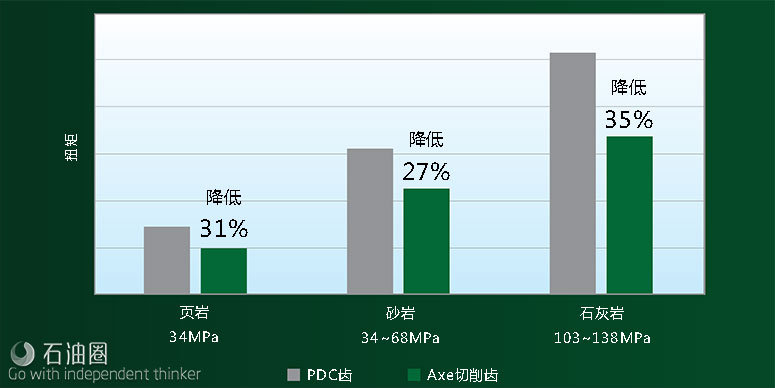

Axe elements employ a unique ridge-shaped geometry that enables a PDC bit to cut rock in a new way—a combination of shearing and crushing. This cutting method achieves at least 22% deeper penetration and removes more formation to provide higher instantaneous ROP using the same weight on bit and rpm applied to conventional PDC cutters. Because Axe elements can be used in many bit designs, the AxeBlade bit can be deployed in a variety of applications in which enhanced ROP is needed to reduce drilling costs. The AxeBlade bit has demonstrated up to 29% improvement in ROP compared with bits using conventional PDC cutters, resulting in rig time and cost savings for operators.

Thicker diamond table on cutter ridge

The new ridged design of the Axe element enables more efficient heat dissipation and better impact resistance, which is achieved through a proprietary blend of polycrystalline diamond grain sizes.

The thicker diamond layer gives Axe elements the ability to withstand a higher concentration of stress at the ridge. When placed along the bit face to form the AxeBlade bit, the ridge cutters exhibit greater durability in formations that damage conventional cutters. Higher

Higher ROP throughout runs

In laboratory testing, a conventional PDC cutter and Axe element impacted a hardened steel block at 7,000 lbf to simulate drilling into a hard limestone formation at 60 ft/h. The results demonstrate that the diamond layer on the cutter ridge, which is 70% thicker than that of a conventional cutter, gives the Axe element increased impact resistance to enable the AxeBlade bit to sustain high ROP throughout the run.

Enhanced control in directional applications

The AxeBlade bit enables better trajectory control in directional applications by reducing torque at the bit, which is achieved by the more-aggressive geometry of the Axe element.

This advantage helps operators achieve better build rates with fewer reactive torque fluctuations while delivering higher overall ROP. The AxeBlade bit maximizes production zone exposure and minimizes NPT by delivering better steering and well placement and completing directional objectives in less time.

Demonstrated torque and ROP improvement

The IDEAS* integrated dynamic design and analysis platform was used to perform a finite element analysis comparing an AxeBlade bit with a conventional PDC bit. In a simulation of rotating and sliding through a shale–carbonate transition with an unconfined compressive strength of 10,000 to 20,000 psi, the AxeBlade bit exhibited better toolface control and steerability with less overall torque and less torque fluctuation.

Testing at the Schlumberger Gould Research Center (SGR) near Cambridge, England, employed a large atmospheric drilling machine (LAM) to compare the drilling performance of the AxeBlade bit with a conventional PDC bit. Drilling through roughly 40 ft of 22,000-psi limestone, the AxeBlade bit enabled significantly higher ROP and required less torque to achieve these ROP gains. Data from a vibration monitoring sub indicated that the bit also reduced lateral vibrations for better borehole quality.

Case Study

AxeBlade Bit Increases ROP 29% and Improves Directional Control in Eagle Ford Shale Interval

Ridged diamond element bit improves drilling rates while enhancing steerability with reduced reactive torque

Challenge

Achieve high instantaneous ROP and enhance toolface control while drilling with a high differential pressure motor in limestone and shale formations, Eagle Ford Shale.

Results

1.Drilled 3,586-ft [1,093-m] interval in 35 hours for an ROP of 102.5 ft/h [31.2 m/h], an improvement of 29% compared with ROP of previous wells.

2.Held toolface, built angle, and reduced reactive torque compared with baseline bits.

石油圈

石油圈