The costs of working over deviated shale wells operating on artificial lift run into the hundreds of millions of dollars per year. Almost half of the failures in these wells is related to either tubing or sucker rod coupling failures, caused primarily by wear damage resulting from couplings contacting the inner tube wall.

Materion, a premier advanced materials solutions provider, will debut its new ToughMet 3 Sucker Rod Couplings at this year’s SPE Annual Technical Conference Exhibition (ATCE) in Houston, Sept. 28-30, 2015.

Materion’s patent-pending ToughMet 3 couplings are designed to maximize production output and significantly reduce the costs of artificial lift operations when used in place of sucker rod couplings made of conventional materials.

ToughMet 3 couplings cut the frequency of sucker rod coupling and production tubing damage, the leading causes of well failure.

Made from a unique temper of copper-nickel-tin spinodal alloy engineered by Materion specifically for use in the oilfield, ToughMet 3 Sucker Rod Couplings resist mechanical wear, thread damage, corrosion and erosion. They are non-galling to prevent damage to production tubing, and they retain their strength, even at elevated temperatures. This combination of attributes minimizes the frequency of workovers associated with couplings made of other materials.

ToughMet 3 Sucker Rod Couplings are the most cost effective solution for eliminating production interruptions caused by sucker rod coupling and production tubing failures.

ToughMet 3 TS 95 properties:

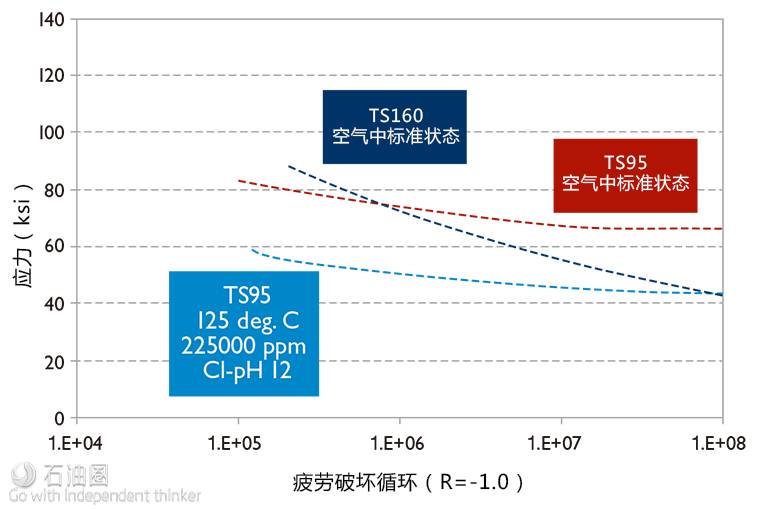

• High strength – Yield Strength > 95 ksi

• Fatigue Strength – > 65 ksi

• High Toughness, CVN > 30 ft-lbs

• Non Galling, Dry Coefficient of Friction < 0.3

• No Chloride SCC or Pitting

• No Sulphide SSC within established NACE limits

• Dimensions for ToughMet 3 Sucker Rod Couplings and Cross Over Sub-couplings conform to API Specification 11B

“Materion is committed to developing and manufacturing advanced, high-performance products that enable our customers’ technologies,” said Bill Nielsen, marketing director for bulk products, Materion Performance Alloys. “We are excited to show SPE ATCE attendees how the unique properties of the ToughMet 3 Sucker Rod Couplings are designed to double the interval between our customers’ well-workovers, effectively reduce one of their major operating costs and increase their earnings by eliminating costly production interruptions.”

Fatigue Strength –ToughMet TS Tempers

ToughMet 3 sucker rod coupling after 6 months of service in sucker rod string: No evidence of wear or metal transfer

ToughMet 3 Sucker Rod Couplings after 17 Months in the Well: No evidence of wear or metal transfer.

Results indicate the ToughMet 3 Sucker Rod Couplings mitigate one of the most common causes of tubing failure thereby reducing workover costs by $100,000 per well per year.

The benefit of one year’s uninterrupted production from a well producing 100 barrels of oil per day at $40 per barrel is $150,000 to 220,000 of pre-tax cash flow depending on how long the well is typically down for a tubing failure workover.

Field Trials

■ 11 deviated wells running in Bakken shale locations

■ Typically 10,000 ft vertical /10,000 ft horizontal

■ Sweet; range of water cut, sand, brine

■ Typically 6 pump strokes per minute

■ L80 production tubing

■ Wells have history of elevated, frequent failure rates for target cause

■ 1 inch slim hole couplings installed in deviated sections both near-surface and deep

■ No failures in 17 months of continuous running

■ 100% of inspected couplings suitable for placement back into service

■ Wells continuing to run

石油圈

石油圈