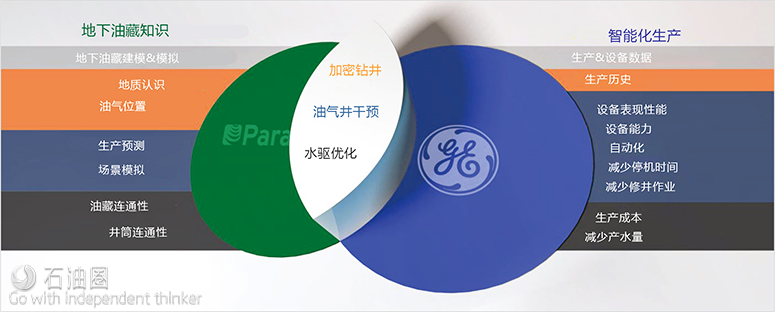

A unique combination of subsurface knowledge and production intelligence enhances efficiency while reducing costs.

In today’s economic environment, operators need to maximize the lifetime of their existing reservoirs while reducing operating costs. To answer that demand, GE and Paradigm have partnered to develop Reservoir Driven Production Optimization (RDPO), a new solution which helps break down functional and technical silos, enabling production teams to make optimal decisions when managing large and/or complex fields. This solution enables operators to exceed production targets and manage operational costs in a variety of ways, including by pinpointing superior infill drilling locations, improving well intervention strategies, and optimizing and predicting flood behavior.

The Challenge: Production Optimization

Operators are challenged to maximize production from their reservoirs, but simply pumping more can result in lower production and higher costs.

Organizations attempt to optimize production by looking at well specific outflow results only, without geologic context. The new offering aims at combining real subsurface knowledge and predictive analytics in order to optimize production field-wide.

What is Reservoir Driven Production Optimization?

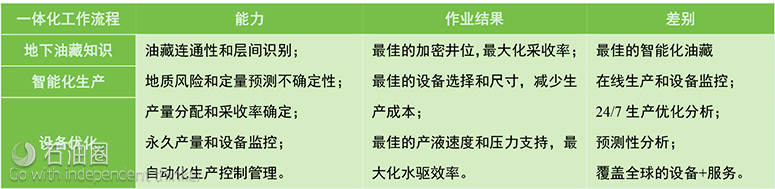

Reservoir Driven Production Optimization requires managing fluid and pressure in the reservoir and properly equipping wells for optimal deliverability, field-wide. In particular, operators can exceed production targets and manage operational costs by:

•Selecting superior infill drilling locations (where to drill)

•Improving well intervention strategies (how to lift)

•Predicting flood behavior (what to inject and when)

Together, GE and Paradigm deliver the intelligence needed to make each of these decisions, in a new and efficient manner.

Paradigm

•Deeper insight into the subsurface

•The industry’s most accurate and predictive reservoir models

GE

•Live production and equipment surveillance

•The industry’s most accurate optimization analytics

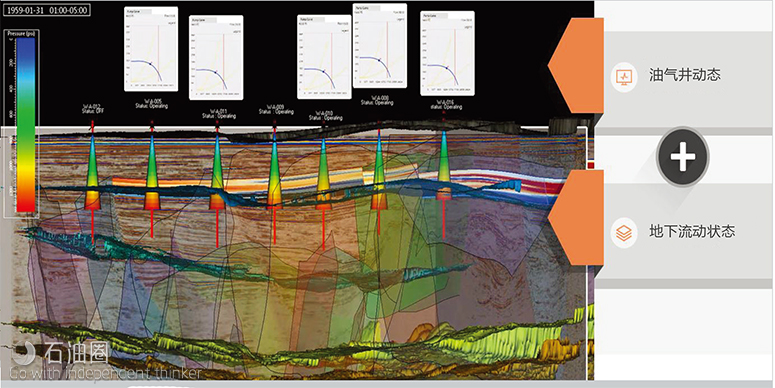

RDPO enables production engineers to use real-time production data such as pressures and flow rates, conduct nodal analysis, and evaluate diagnostics via integration with a 3D model of the subsurface. This leads to a better understanding and prediction of the impact of production intervention before taking costly and potentially adverse actions.

The offering is delivered as a turnkey solution based on a combination of GE and Paradigm software and services, including GE FieldVantage™ for Production Monitoring, Paradigm SKUA-GOCAD™ for Reservoir Modeling and a full range of geotechnical and engineering services.

Armed with a clearer understanding of the reservoir geology, permanent monitoring of wells, and predictive analytics, operators are better equipped to understand risks and act upon them.

RDPO offers added value for:

•Fields moving from development to production

•Mature/rejuvenated fields

•Marginally economic fields

•Complex fields

•Large fields

Reservoir Driven Production Optimization combines well performance data with subsurface flow to optimize production field-wide.

石油圈

石油圈