在二次增产作业中,目标井段与井筒隔离一直是业界难题。常规作业存在能耗高、作业时间长等问题,OptiStriker跨隔封隔器系统可完美解决上述难题,可与连续油管配合使用。

来自 | BakerHughes

编译 | 张德凯

贝克休斯OptiStriker™跨隔封隔器系统包括大直径封隔器和耐用、可回收的连续油管式封隔器,可提供泵入速率高达20bpm,最高工作压力差10000psi,各项性能均为业内顶级,增产作业更加快速,能够实现射孔段定向改造作业,大幅提高产量,可实现增产作业最优化、产量最大化,是一种非常有效的增产改造方案。

在套管井作业中,OptiStriker的两个封隔器相互配合,跨越覆盖目标作业段,将其隔离。这种隔离可以引导井下液体流动,液体会流向最初增产作业中没有处理或开发不完全的产层。封隔器坐封后,工作人员可通过连续油管或是修井管串将增产液体和支撑剂泵入作业段。

定向增产作业的优势之一是避免了过量的药剂使用和能源消耗,在保证产层增产作业效果的同时,最小化操作要求。相比于常规增产技术,定向增产作业可降低30%作业成本,作业速率达到最大,增产效果最佳。井下液体可以由最初的射孔轨迹流入井筒,也可以通过OptiStriker系统的喷砂射孔枪重新射孔,避免了重新下钻、射孔作业,节约作业时间。

OptiStriker系统的机械坐封封隔器性能稳定,可多次重复坐封、解封使用,密封性能可靠,应用灵活,一次下钻即可完成不同产层段的增产作业。当OptiStriker与2-7/8in的连续油管配合使用时,不会产生任何的流体流动受阻问题,操作人员可以放心的泵入高流量、高含沙量的泥浆,最高泵入速率达20bpm,提高了地层缝隙网络的复杂性和产层生产潜能。

与业内其他定向增产系统使用抽汲皮碗进行井筒隔离相比,OptiStriker的封隔器在密封时只与套管壁接触,在系统上下提拉的过程中,不会对套管壁造成摩擦、损毁伤害,延长了系统的使用寿命。此外,OptiStriker系统的封隔器具有非常出色的膨胀性能,对于在之前作业中受到磨损的套管也能完全密封,提高了增产作业压力的上限,消除了液体漏失风险。通常来说,液压坐封封隔器都存在着液压管线堵塞的风险,但OptiStriker的封隔器采用机械方式坐封(线性运动),不存在此类问题。为了最大化应用范围,该系统还具有紧急释放功能。

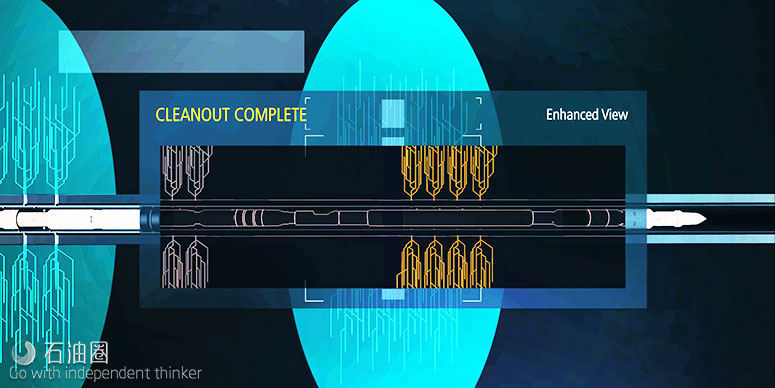

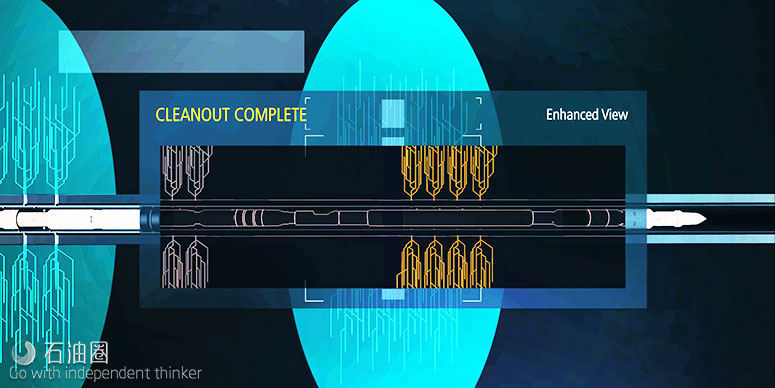

当近井筒区域需要通过清洁来提高液体流动性时,作业人员可使用连续油管注入酸性药剂,这样还方便了循环清洗的进行,使清洁作业更加快速,井筒得以更快投入生产,此类设计也是OptiStriker的一大应用优势。在某些井筒完整性较差的井段,可以使用连续油管作为替代泵入方案。在完成增产作业之后,OptiStriker系统将被完全从井筒中移除,井筒内径不会受损,方便后期作业和生产的进行。如果将OptiStriker与贝克休斯的EasyReach润滑系统(可大幅度降低工具与井筒摩擦系数)配合使用时,其在水平井中的作业深度可成倍增加,连续油管的作业深度最高可达10000ft。

在每一项增产作业开始前,贝克休斯的现场专家会对井筒的历史生产数据进行检查,分析不同产层的生产能力,之后做出诊断(包括注入井测试、微型压裂和反排测试),保证作业计划最适合。此外,工作中和完井后的井筒监测和分析还可用于判断增产作业的效果。

应用范围

1.二次增产作业;

2.产层诊断和微型压裂测试;

3.液体和凝胶注入;

4.非常规油气藏;

5.套管井作业;

6.垂直井和水平井。

特点与优势

1. 定向增产作业:

—精准实现目标产层增产作业;

—作业前、后测试模块消除了不确定性;

—增产液体、药剂体积精准控制;

—降低增产液体使用量和燃料消耗;

—简化作业流程,工作逻辑更加明确。

2. 封隔器耐用,可重复使用:

—一次下钻可完成多个产层段的作业;

—产品品级更高,作业主动性更强;

—封隔器为机械坐封,可靠性更高;

—不损失井筒内径,无需进行二次压裂作业;

—相比于其他机械坐封方案,价格更低。

3. 封隔器直径更大:

—增产液体和药剂的本如速率更高,作业效率更高;

—可与连续油管或是修井管串共用。

4. 双卸载设计:

—工具顶端可进行循环洗井作业;

—简化洗井和压力均衡设计;

—井下滤出物清除更加快速、简单。

The Baker Hughes OptiStriker straddle packer system enables aggressive, targeted restimulation of individual perforation clusters in existing wells to boost production—efficiently and effectively. The system features a large ID and two rugged and resettable coiled tubing (CT) packers, offering an industry-leading pump rate of 20 barrels per minute (bpm) and a differential pressure rating of 10,000 psi (689 bar) to enable high-rate, high-volume treatments that optimize well restimulations and maximize production.

During cased hole operations, the two packers work in unison to straddle and isolate individual clusters within the wellbore. This ensures that fluids are directed to areas that may have been untreated or undertreated during the initial stimulation. After the packers are set in the wellbore, a controlled volume of fluid and proppant can be pumped through the CT or workover tubulars and delivered to the desired areas. This targeted stimulation technique uses only the amount of fluid and horsepower needed to treat each cluster, minimizing operational requirements and costs by more than 30% compared to other restimulation techniques, while maximizing the speed and effectiveness of treatments. Fluids may enter the formation through the original perforations, or additional perforations can be created using the system’s sand-jet perforator, eliminating the need for a dedicated tubing-conveyed-perforating run.

The OptiStriker system’s mechanical-set packers are designed to reliably set and unset numerous times, enabling flexible and thorough wellbore coverage in a single trip. When used with CT sizes of up to 2? in., the tool does not create any flow restrictions, allowing operators to confidently pump high-volume, high-sand-concentration slurries at up to 20 bpm to enhance fracture network complexity and to increase production potential.

Unlike other targeted stimulation systems that use swab cups to isolate zones, OptiStriker packers only contact the casing wall when they are set. This prolongs system life by eliminating damage and wear caused by rubbing against the casing wall as the assembly is moved in the well. High-expansion capabilities ensure the packers establish a complete seal—regardless of erosion damage from previous operations or casing irregularities—to enable higher treatment pressures and to eliminate fluid leak-off. And risks associated with plugged hydraulic conduits are eliminated because the packers are actuated and released using only linear movement. The system incorporates a contingency release feature that can be used if needed.

When the near wellbore requires cleaning to enhance conductivity, acid can be spotted via the CT. CT also offers easy circulation and wellbore cleanouts, enabling quick recoveries from screenouts through a purpose-built cleanout mechanism. Pumping treatments through the CT also enables treating wellbores where casing integrity is a challenge. Because the entire OptiStriker assembly is removed after operations are complete, the original production inside diameter (ID) is maintained, helping simplify future access. When combined with Baker Hughes EasyReach? lubricant—which reduces the coefficient of friction in cased hole wells—horizontal reach capabilities almost double, helping make successful CT applications in lateral lengths greater than 10,000 ft (3048 m) routine.

Before any restimulation job, Baker Hughes experts can review historical production data, analyze the well’s production contribution profile, and perform diagnostics—such as injectivity testing, mini-fracs, and flowback testing—to ensure optimal program design. Monitoring and analysis can be performed during and after the job to confirm treatment effectiveness.

Applications

· Re-stimulation operations

· Formation diagnostics and mini-fracs

· Fluid and gel injection

· Unconventional oil and gas wells

· Cased hole wellbores

· Vertical and horizontal wells

Features and Benefits

1.Targeted stimulation

—Ensure precise delivery of treatments to desired areas

—Enables pre- and post-stimulation testing to eliminate treatment uncertainty

—Delivers controlled treatment volumes

—Reduces fluid and horsepower requirements

—Decreases operational footprint and simplifies onsite logistics

2.Rugged resettable packers

—Enable treatment of multiple zones in a single trip

—Support aggressive treatments with enhanced ratings

—Improve reliability through fully mechanical operation

—Maintain the ID of host liner without post-frac intervention

—Provide a cost-effective alternative to other mechanical isolation methods

3.Enlarged packer ID

—Enables delivery of high-sand-concentration slurries at high pump rates and volumes

—Supports deployment on coiled tubing or workover tubulars

4.Dual unloader design

—Enables circulation at the top of the tool

—Simplifies cleanout and equalization

—Supports quick, easy self-recovery from screenouts

未经允许,不得转载本站任何文章:

石油圈

石油圈