The only wells that are straight or follow a smooth curve are in the pictures in well plans. Real wellbores are shaped by the mechanics of directional drilling tools, the skills and attention of drillers, the force of gravity, and the path followed by hydrocarbon-rich seams of rock.

“Well path modeling commonly generates smooth curves, whereas an actual well contains severe doglegs and other irregularities,” said Robello Samuel, technology fellow, drilling, at Halliburton. A major interest for Samuel is creating measures to address a problem he raised in a 2009 paper (SPE 124710): “There are not clear criterion for defining the quality of the wellbore.”

There are several companies with methods for estimating the frictional force added by irregular wellbores,which grew out of the long-standing effort to more accurately measure the path of narrow holes drilled miles underground.

They are seeking more realistic measures of wellbore quality than those offered by established formulas, such as the minimum curvature method, which assumes the well follows a smooth curve based on the shortest possible radius from the previous measurement point.

It is an elegant formula, but years of experience and testing have shown that it poorly describes the work of rotary steerable tools or directional drilling tools using bent mud motors to build curves. In the process, the data sent back to the surface can lead to errors in critical measures, particularly in the total vertical depth. The level of uncertainty is greater when using a bent housing, but neither tool is immune to error.

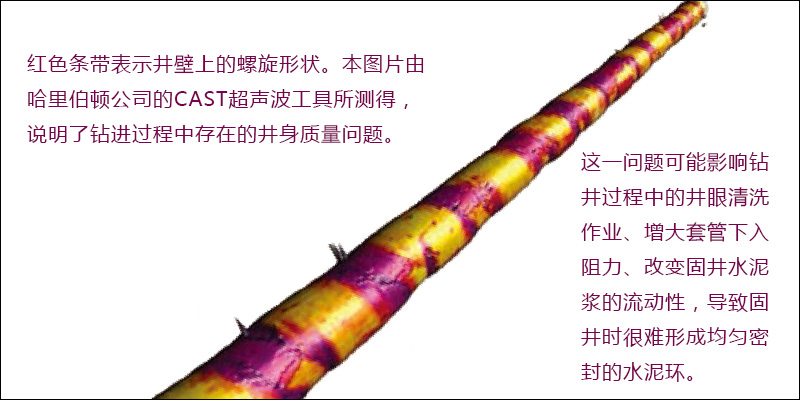

Crooked wellbores may undulate with doglegs, spiraling, and washouts.In a word, it is tortuous. Rocks can test a driller’s ability to keep drilling on course. Gravity also can also alter the course of the drill bit to below the planned course.

Drilling advances that made it possible to target smaller deposits have complicated drill bit navigation. Using directional drilling to follow the unpredictable path of a pay zone “introduces well tortuosity almost by design,” said Cam Matthews, a fellow at C-FER Technologies, a not-for-profit oil industry research and testing center.

Adding to the uncertainty was the advent of topdrives, which allowed larger rigs to add 90 ft of pipe at a time to the drillstring, compared to only 30-ft segments on rigs equipped with a kelly drive. An unintended downside was the reduction in the number of times that data are gathered to once every 90 ft, when the mud pumps are turned off for connections.

In 1993, Matthews coauthored a paper (SPE 22852) warning of the measurement errors that could be introduced by wider gaps between survey measurements. Edward Stockhausen, a geosteering specialist for Chevron, spent years working to identify the potential magnitude of such errors, which could lead to an error of ±25 ft in total vertical depth, according to a 2003 paper (SPE 79917).

A problem with a bent-angle motor is the potential introduction of small errors each time it switches from sliding to rotating mode to drill forward. While rotary steerable tools are less prone to error, they are not not immune. During a panel discussion at the recent SPE Annual Technical Conference and Exhibition, Stockhausen said using both stationary measures and streams of continuous location measures offer a more accurate fix on location, but he is still seeking a satisfactory formula for combining the two.

The payoff for Stockhausen’s dogged pursuit of errors can be significant. In a large, offshore field driven by water rising from below, a 1-foot difference in the total vertical depth, can change the ultimate oil recovered by 100,000 bbl.

At the ATCE, he presented recent work demonstrating small measurement errors in logging tools equipped with two gamma rays (SPE 175048), which if unnoticed could significantly reduce the rock contacted when geosteering through a formation.

“The significant thing is if you do not pay attention to what you do, you are going to get the same things [errors] over and over,” Stockhausen said.

New Tools

As improved measurement tools reveal smaller wellbore features, there is a growing body of work aimed at measuring the physical effect of the flaws.

There have long been quality measures such as the drilling difficulty index and the wellbore quality scorecard. None satisfy Samuel whose focus is on developing formulas to drill more systematically, as evidenced by his book, 501 Solved Problems for Drilling.

The drawback of the available measures, he said, is that they are conceptually similar to medical ratings, which rank symptoms to assess if a patient is at risk of a heart attack, but do not provide direct evidence of the condition. These subjective measures leave it up to the “whims of users” to decide how much weight to apply to them, Samuel said.

Samuel developed a mathematical formula to calculate the energy required to overcome friction caused by a tortuous wellbore, which is termed well profile energy by Halliburton. It uses the well survey data gathered every 90 ft to model the well path and calculates the minimum energy needed to move an elastic beam through a hole in that shape.

The company is working to build it into dashboards used by drillers so they can see how the twists and turns of the wellbore being drilled will affect the torque and drag required to push casing into the wellbore.

“With a scorecard, it is rated high or low. When you do well profile energy, it is mathematical and physical,” Samuel said. In an interview, he showed a display under development with a graphic of a drillstring moving horizontally surrounded by bubbles displaying data, including the torque and drag added by wellbore tortuosity as of that point.

Halliburton is also directly measuring wellbore geometry effects by installing strain gauges in bottomhole assemblies that measure the magnitude and direction of the force caused by Wellbore irregularities.

And it is competing with Schlumberger, which has published papers on quantifying the effect of tortuosity and is looking for ways to improve drilling tools.

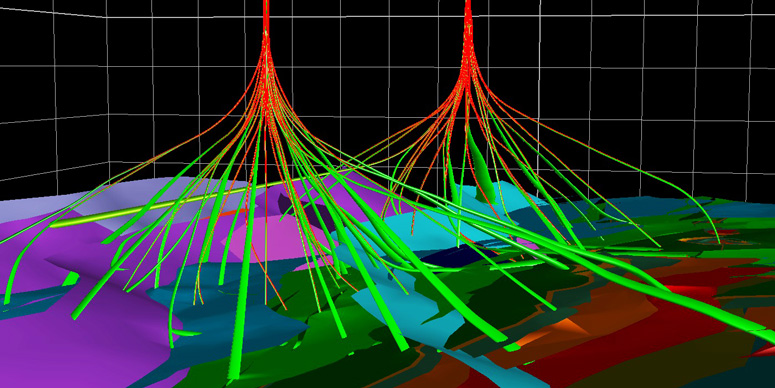

Gyrodata, which is known for making a line of precise well survey tools based on gyroscopes, has developed a method to use foot-by-foot wellbore measurements, which are used to create a 3D model to calculate the physical effect of tortuosity.

The method outlined in a paper early this year (SPE 173103) has inspired a growing number of its applications by engineers managing completions and production, said Steve Mullin, director of marketing for GyroData.

New data will spark new arguments about what it means. Samuel pointed out that many of the small variations in the well path are often not observable inside the stiff walls of casing. Mullin responds that users will find value in details not seen in standard surveys done every 90 ft to 100 ft.

“A 100-ft survey gives the impression that the well is smooth. Usually it is not smooth,” Mullin said. “Our survey is showing all the bends between those points.”

石油圈

石油圈