Durable, fit-for-purpose technologies for riser cleaning and validation

The presence of drilling fluid, solids, and ferrous debris in deepwater mud-to-brine displacements can negatively affect completions, production, and costs.

Conventional cleaning processes are overly simple and often ineffective. During fluid transport, these cleaning tools deviate the fluid direction before it reaches the surface, causing a corresponding drop in velocity that causes entrained debris to drop out.

The M-I SWACO marine riser cleaning assembly addresses the limitations of standard cleaning methodologies by eliminating the fluid bypass, thereby maintaining high velocities and high collection and carrying capacity.

This assembly is the industry’s only integrated tool system that cleans the riser of drilling fluid, solids, and ferrous debris—and validates the assembly’s performance.

Unique riser-centric solution for debris-free deepwater displacements

Applications

■ Deepwater displacement

■ Postmilling debris removal

■ BOP jetting

■ Emergency disconnect operations

Benefits

■ Enhances cleaning with the ability to clean the riser and validate effectiveness to within 30 ft of BOP stack

■ Improves time and cost effectiveness by optimizing displacement and completions in costly deepwater environment

■ Enables further efficiency through compatibility with SMART 3D* displacement strategy

Features

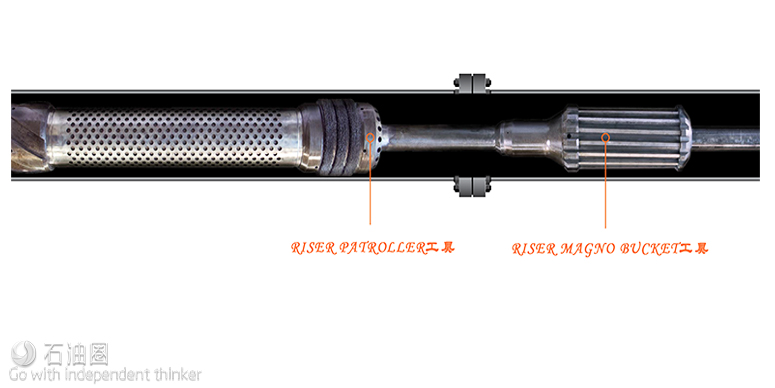

■ Integration of RISER PATROLLER* deepwater validation tool and RISER MAGNO BUCKET* deepwater magnet tool

■ Built-in cleaning validation

■ Extremely durable design

■ Large flow area

■ Redundant, nonrotational brushes

■ 1-bbl collection capacity

■ Consistent fluid flow path

■ Multiple trip capability

Integrating wellbore productivity technologies

Often used in concert with the HEAVY-DUTY WELL PATROLLER* advanced validation tool and other cased hole displacement tools, the marine riser cleaning assembly has emerged as an integral component of our SMART 3D displacement strategy, which incorporates the latest chemical, mechanical, and hydraulic technologies into an integrated wellbore cleaning package.

RISER MAGNO BUCKET tool

The RISER MAGNO BUCKET deepwater magnet tool captures and retrieves the metal debris dislodged during riser cleaning operations. The tool can be run above the RISER PATROLLER tool or a PUP RISER BRUSH* polishing tool.

The tool features a series of magnetic blades that are locked onto the junk bucket and attract metallic debris that falls from the riser. As fluid flows past the outside of the RISER MAGNO BUCKET tool during circulation, ferrous debris is retained in the valleys between the magnetic blades on the tool’s OD, keeping ferrous debris away from the ID of the riser.

Nonferrous debris bypasses the OD of the RISER MAGNO BUCKET tool. When a drop in annular velocity occurs above the tool, larger pieces of nonferrous debris fall out of the fluid flow into the junk bucket. When all circulation is completed, the tool—complete with captured debris—is pulled to surface, where debris can be easily removed and the assembly run back in hole if required.

Riser patroller tool

Complementing the RISER MAGNO BUCKET tool, the dual-function RISER PATROLLER deepwater validation tool cleans the riser’s inner walls and filters the entire fluid column in the riser to ensure that all entrained debris is captured within its filter, which has a capacity of one barrel.

A triple-stacked set of nonrotating and durable brush rings scours and wipes the riser ID during tripping. These brush rings help centralize the tool assembly, allowing it to freely rotate on the mandrel. The tool requires no balls, darts, or other external activation devices, operating instead simply by running in and tripping out of the riser.

After the tool is retrieved at surface, its built-in validation screen, which is supported and protected by a perforated shroud around the outside of the screen, enables validating that the riser is free of debris. The large flow areas of the validation screen and valves help avoid surge and swab while tripping.

The validation capability of the RISER PATROLLER tool ensures that all drilling residue has been collected and removed throughout the displacement. The built-in brushes ensure that all debris remaining on the riser ID is wiped off during the trip, and all fluid is filtered through the durable shrouded screen. The RISER PATROLLER tool can be cleaned using the rig’s vacuum system for onsite debris extraction.

石油圈

石油圈