贝克休斯推出的SureFIELD全球远程数采装置及通信工具能够从任意连接地点对井进行连续远程监测,是SureFIELD产品组合的一部分。

来自 | Baker Hughes

编译 | 张毅

大数据的变革已经悄然渗入人们的生活,石油行业一些先进的公司也尝试着使用大数据分析,结合移动互联网和物联网技术,大力发展“智能油田”,更精准的判断井位,降低钻井事故率,降低勘探、集输、炼化和销售各板块的成本,非常规油气的勘探也越来越精准,另外,对公司日常活动进行大数据技术的深入挖掘,公司可以高效预测未来真实的情况。总之,大数据已经成为油气行业未来的发展趋势。

贝克休斯SureFIELD™全球远程数采装置及通信工具用于采集并传输井场传感器及地面控制器的实时数据,能够实现从任意连接地点对井的连续远程监测。此装置是贝克生产决策服务(PDS)产品组合的一部分,设计用于未安装监测系统的井或者用于已安装SCADA系统的井,旨在增强井下仪器仪表的数据回收。SureFIELD全球远程数采装置配有卫星通信解调器的控制器,能够通过卫星按照预设时间间隔上传数据,或者按需进行不间断传输。

系统安装就位后,操作人员便能够浏览实时生产数据,其中包括电潜泵工作参数、分布式温度传感系统参数、永久式压力/温度计及流量计参数等。此装置同时能够对油气井生产装置进行安全、双向的控制,从而实现增产目的。

SureFIELD全球装置来自于贝克休斯极具可靠性的SureFIELD产品组合,该组合的关键组成还包括SureFIELD DataHub SCADA系统以及Vision 网络应用程序,主要用于数据浏览、趋势跟踪及报警。通过SureFIELD DataHub装置收集的数据经过处理、缓冲和压缩后,由SureFIELD全球通信装置发送,最终呈现在台式机或笔记本上的Vision用户界面上。相较于先前的系统,最新一代SureFIELD全球装置能够匹配更高带宽,重新采用NEMA4标准外壳包装,以对抗恶劣作业环境。

应用范围

1. 偏远井;

2. 电潜泵井;

3. 安装仪器仪表的生产井或回注井。

特征与优势

1.先进的卫星技术:

– 提供安全的全球覆盖;

– 能够耐受最复杂恶劣的气象条件。

2.直接IP连接:

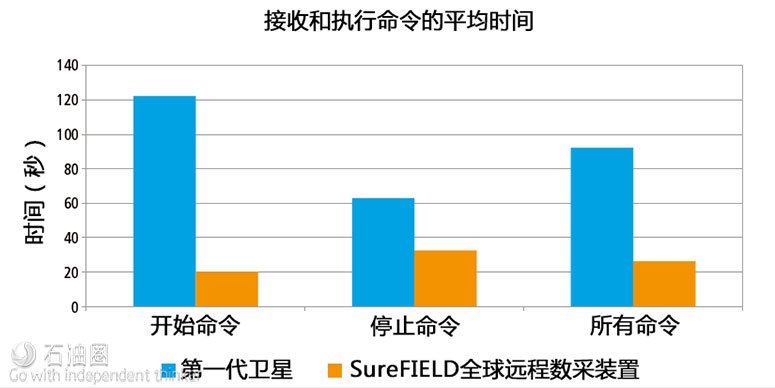

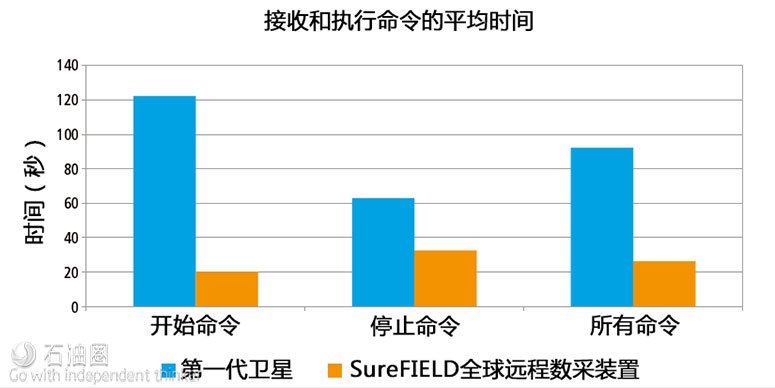

– 通信速度为第一代卫星系统两倍;

– 高效处理大量数据。

3.与贝克休斯电潜泵及IPS设备无缝衔接:

– 能够高效安装;

– 免去了配置文件。

4.通过ModBus通信协议与单个或多个装置配合工作:

– 通过简单配置便能够与多种油田装置匹配;

– 刷新频率可调使得数据采集更灵活简便。

5. 远程管理:

– 降低监测操作成本;

– 允许现场装置的远程控制。

应用案例1

一名操作员通过SureFIELD全球装置接收到实时反馈,得知一个偏远井的电潜泵由于电机过热没有排量,且有损坏风险。凭借SureFIELD通信装置,操作员工远程关井,避免了电潜泵的进一步损坏。

应用案例2

另一个实例是操作员的井站安装了SureFIELD全球系统与贝克休斯智能井系统(IWS)。一口偏远井的SureFIELD井下传感器检测到水侵。操作员利用SureFIELD全球通信功能远程调整阀门设置并且在水进入处理设施前使其得到控制,省却了派人员到现场调整阀门的过程。

当前,油气田开发已进入数字油田阶段,数字油田的应用领域不断扩大,技术持续发展,应用情景日趋广泛。据介绍,通过应用智能井、综合生产模型、监控系统和生产优化等技术,数字油田可以有效地减少井数及非生产时间,提高设备利用率及油井动态响应程度,优化地面开发及物流管理,最终达到增加产量、降低运营成本、提高生产效率和安全性等效果。从统计数据看,数字油田的应用通常可以使采收率提高2~6个百分点,使产量提高2%~8%。

The Baker Hughes SureFIELD? Global remote data acquisition device and communication tool gathers and transmits real-time data from sensors and surface controllers at the wellsite, enabling continuous, remote well-monitoring from any connected location. The device is a part of our Production Decision Services (PDS) portfolio, and it can be used in wells without existing monitoring systems, or in wells with existing SCADA systems to enhance data recovery from downhole instrumentation. The SureFIELD Global device integrates a controller with a satellite modem, allowing it to report data via satellite at preconfigured time intervals, or on demand 24/7.

When the system is in place, operators gain access to real-time production data including feedback from electric submersible pumps (ESPs), distributed temperature sensing (DTS), permanent pressure/temperature gauges, and flow meters. The device also can be used to increase production by enabling secure, two-way remote control of production devices at the well.

Two examples may help to illustrate how the SureFIELD Global device can work in the field:

An operator received real-time feedback from the SureFIELD Global device that their ESP at a remote wellsite was near a no-flow condition with an overheated motor, and was in danger of failure. Using the SureFIELD Global communication device, the operator remotely stopped the well and saved the ESP from a critical failure.

In another example, an operator had a SureFIELD Global system installed along with a Baker Hughes intelligent well system (IWS). SureFIELD downhole sensors at the operator’s remote well began to detect and communicate a water breakthrough event. Instead of sending personnel out to the well to adjust the valve, the operator used the SureFIELD Global communication function to remotely change the valve setting and control the water before it reached the processing facility.

The SureFIELD Global device is part of the reliable Baker Hughes SureFIELD portfolio. Other key components of the portfolio are the SureFIELD DataHub SCADA system and the Vision web-based monitoring system for data viewing, trending, and alarming. Data gathered by the SureFIELD DataHub device is processed, buffered, compressed, and then transmitted by the SureFIELD Global communication device. The data are then displayed using the Vision user interface on a PC or laptop. This latest generation SureFIELD Global device has higher available bandwidth than previous systems, and it is repackaged in a NEMA 4 enclosure for protection against harsh environments.

Applications

1.Remote wells;

2.ESP wells;

3.Instrumented production or injection wells.

Features and Benefits

1.Advanced satellite technology:

—Offers secure global coverage;

—Withstands most atmospheric conditions.

2.Direct IP connection:

—Communicates twice as fast as first-generation satellite systems;

—Handles large volumes of data efficiently.

3.Seamless interface to Baker Hughes ESP and IPS products

—Enables efficient installation;

—Eliminates configuration files.

4.Works with one or multiple devices via ModBus protocol:

—Configures easily for a wide range of oilfield devices;

—Provides flexibility to gather data with adjustable polling rate.

5.Remote management

—Reduces surveillance OPEX;

—Allows for remote control of field devices.

6.Oilfield ready:

—Prepackaged in a rugged NEMA 4 enclosure.

未经允许,不得转载本站任何文章:

石油圈

石油圈