To handle the large volume of flowback water that comes with fracking, experts from NOV’s Process and Flow Technologies business unit have developed an optimized saltwater disposal facility design with updated equipment selection and a safer, more efficient layout.

With a large inventory of drilled and uncompleted wells in the U.S., hydraulic fracturing activity will likely be a first step toward recovery in the North American oil and gas industry. When that happens, large volumes of flowback water will require operators to increase the quantity and capacity of injection wells and saltwater disposal (SWD) facilities.

A lesson learned from the shale boom of the last five years is that the high concentration of oil and the wide range of water composition and contaminants in most flowback water is a challenge for conventional SWD facilities. An optimized SWD facility design was developed by NOV to help operators with these challenges, changing the way the industry looks at SWD by updating equipment selection and creating a safer, more efficient site.

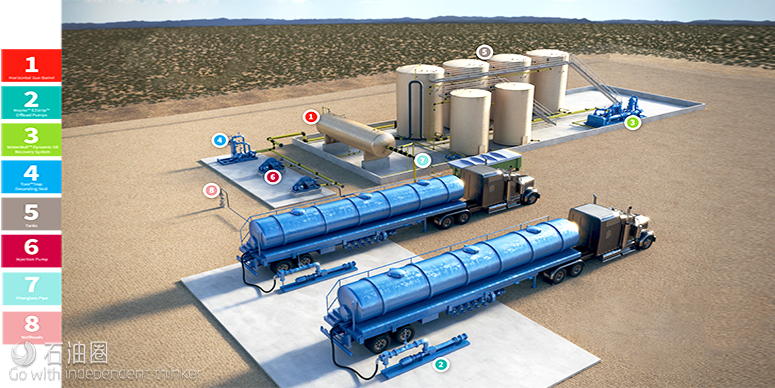

Equipment we recommend for our optimized site layout includes:

Horizontal Gun Barrel – Far more efficient than traditional or enhanced vertical gun barrels, our horizontal gun barrel is engineered with saltwater disposal in mind. A single horizontal gun barrel replaces multiple offload tanks, gun barrels, and transfer pumps that are conventionally used. With our unique online solids removal, tank cleanouts can be eliminated. Our system completely eliminates the re-pumping of water into tanks, and produces cleaner, drier oil.

Moyno™ Offload Pumps – The non-shearing action of our Moyno pump is an ideal offload solution that helps grow oil droplet size, allowing better recovery. Able to unload a standard tanker in under 10 minutes, our Moyno progressing cavity pump technology has an 85+ year history of success in industrial use.

WaterWolf™ Dynamic Oil Recovery System – Our breakthrough WaterWolf Dynamic Oil Recovery System is a revolutionary water treatment system that recovers oil and suspended solids from produced water in a single stage of treatment, without the use of expensive chemicals or filters. This skid-mounted solution combines the non-shearing action of progressing cavity pumps with deoiling and desanding hydrocyclones, creating a highly efficient oil recovery solution with as much as 20 additional barrels recovered for every 10,000 barrels of water produced.

Tore™Trap Desanding Skid– With some of the components of our WaterWolf system, the ToreTrap skid is another highly efficient solids removal system. Able to remove fine solids down to 10 to 15 microns, the ToreTrap desander allows solids removal without the disruption of process. Reduced solids in the stream leads to less filter change-outs, helps eliminate tank cleanouts and reduces the opportunity for damage of pumps and injection wells.

Tanks – We provide steel and fiberglass tanks to suit your site needs. With complete install of pedestals, walkways, stairs and structural elements, we make the process easy. Whether you need small 400 bbl or large 1000 bbl tanks, we can find the solution that fits your site requirements.

Injection Pump– With a century of pump manufacturing under our belts, we have top of the line injection pumps ready to suit your needs. With either reciprocating or multistage centrifugal injection pump package options, our field-proven, reliable pumps are backed by a global technical support team.

Fiber Glass Pipe – We provide technical expertise and superior technology that maximizes performance and lifecycle economics of your project. With a proven history of jointed and spoolable products with global support you can depend on, our composite systems are engineered to increase efficiency, reliability and reduce costs. We work with you to develop a proven corrosion resistant answer that is lightweight and easy to install. Should an alternative piping material be preferred, we can handle upon request.

Wellheads– We design and manufacture a wide range of wellhead and production tree assemblies for use with all well service conditions and all types of completions. All wellhead systems are manufactured to API 6A requirements as a basic minimum, in a plant that is API Q1 and ISO 9001

Optimized Design

Traditional SWD facilities host a large battery of tanks, vertical gun barrels and a centrifugal pumping system with heavy dependency on treatment chemicals for oil/ water separation. The use of centrifugal pumps that shear oil droplets and inefficient vertical gun barrels result in lost oil revenue and impaired well disposal capacity. An increase in solids concentration results in numerous tank cleanouts with the potential for environmental contamination and increased safety risk for operators and contractors.

The optimized SWD site design has simple yet effective hydraulics and a compact footprint that reduces capital cost, minimizes operating costs, maximizes oil recovery, optimizes well injectivity, reduces complexity and improves operator safety.

Marcellus Facility Redesign

ClearWater Solutions built an SWD facility east of Cambridge, Ohio, in 2014 to serve the Marcellus Shale market. Following conventional wisdom, the facility design included a centrifugal pump offload system and a set of five frack tanks for truck offloading and water holding capacity. Saltwater was pumped from the tanks using a second centrifugal pump into a set of two vertical gun barrels followed by 10 dirty water tanks.

Like most public SWD facilities, revenue for ClearWater Solutions is generated from disposal fees. The company’s ability to make higher returns on their investment depends heavily on the additional revenue generated from the sale of recovered oil. In the first year of operation, the facility recovered and sold only one truckload of oil. In addition, the need to clean out solids that accumulated in the frack tanks and to clean out the non recovered oil from the well every 60 days greatly increased the company’s operating costs.

Knowing the facility should recover more oil, the company recognized that its conventional equipment was failing to deliver. ClearWater Solutions learned during a consultation with the NOV engineering team that NOV had validated the commonly held belief that progressing cavity pumps (PCPs) can coalesce oil droplets in saltwater while developing its WaterWolf dynamic oil recovery system. Armed with these data, ClearWater made the decision to upgrade its pump offload stations with PCP technology. The company built two new truck offload lanes equipped with Moyno PCPs.

However, the new pumps alone were not the complete solution. The frack tanks at the front of the facility were catching both oil and solids requiring frequent cleanouts, and preventing oil recovery. Company management opted to replace the frack tanks with a horizontal gun barrel (HGB) to eliminate tank cleanouts and improve oil recovery.

The HGB design was first introduced and commissioned by NOV in an Eagle Ford Shale SWD facility in South Texas. The HGB is a pressure vessel-based design and is equipped with Tore Online Vessel Desanding system. It is built to immediately follow the PCP offload station and is used to eliminate any further pumping of the water and shearing of the oil prior to the injection pumps.

Seeing Results

In February 2016 NOV commissioned the Moyno PCP offload station and HGB at the ClearWater facility. The operators noticed a change right away when the level sensors on the oil tanks started to rise for the first time in the past year.

Within a week of operating the new system, the company sold a full truckload of high-quality oil recovered from the facility. In the first four months of operation since the new system was commissioned, the facility has averaged one to two truckloads of high-quality oil sales per month with zero tank cleanouts.

“Now we have on average 24 to 36 pickups of high-quality oil per year compared to our initial one pickup per year,” said Brad Erdman, vice president of ClearWater Solutions.

The company’s overall operating costs have decreased due to its ability to capture more oil before it goes into the well, keeping the well open for longer periods of time before needing to shut down for acid treatments.

“We were doing acid jobs every 60 days, but now it is quarterly or less, which is at least double the time between acids job,” Erdman said. In addition, the quantity of filters used also has decreased, further contributing to the lower operating costs that are now realized.

Building for The Future

ClearWater Solutions is now building a second facility based on the new optimized SWD process that incorporates the Moyno PCPs and HGB designs. In addition, the new facility will feature a robust and corrosion-resistant fiberglass piping system and NOV’s newest addition to the optimized SWD process called EZ Skim. This patent-pending feature works with the elements of the HGB to simplify oil recovery from the dirty water tanks. By turning three valves, the operator can set a tank to skim mode and walk away.

EZ Skim sets the water level at just the right height to recover all of the floating oil without spills or equipment damage and without distracting the operator from other important tasks such as servicing the trucks that line up in the driveway.

The skimmed oil is returned to the HGB, where it can be recovered as a dry oil product without contaminating oil in the sales tank. Once a tank has been fully skimmed, it can then be emptied down to the outlet line without pushing valuable oil to the injection pumps. This lets the operator pump his entire tank battery down to its lowest level, giving him full capacity to receive water from the next wave of inbound trucks.

石油圈

石油圈