Halliburton’s EquiSeal Conformance service is specifically designed to help control unwanted fluid production, water or gas, in horizontal or highly deviated wellbores. Depending on fluid density differences and wellbore deviation, conventional Conformance treatments may tend to slump/rise along horizontal or highly deviated sections, compromising the placement accuracy and overall success of the treatment. The stress-dependent (thixotropic) rheological properties of EquiSeal Conformance service provides rapid viscosity increase during placement, allowing the treatment to remain in place until in-situ crosslinking occurs at a predicted time, helping to provide a competent seal across the targeted area. Halliburton’s EquiSeal service is the only thixotropic Conformance technology specially tailored to horizontal applications in the oil and gas industry today, helping operators achieve the lowest cost per BOE through custom chemistry.

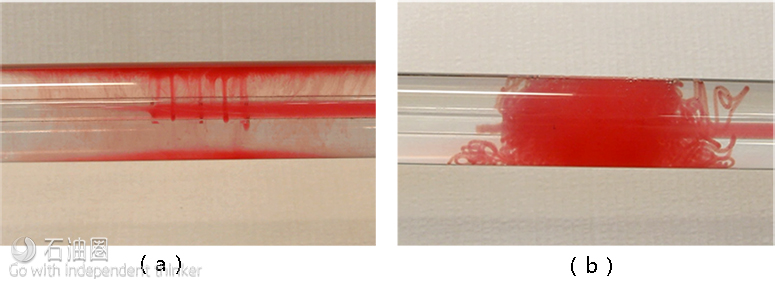

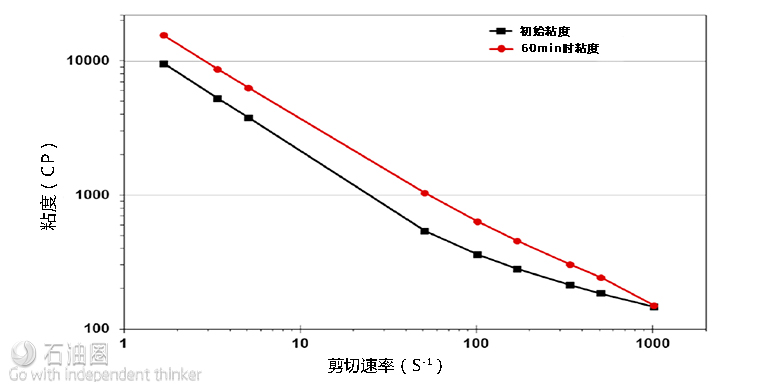

Laboratory test showing the stress-dependent (thixotropic) viscosity profile of EquiSeal Conformance service compared to conventional sealants > Test fixture shows a water-filled pipe-in-pipe configuration with the treatment being pumped into the inner pipe, then exiting into the annular space: (a) Conventional sealant spreads/diffuses down the annular space, thus not providing a competent seal at the desired location; (b) EquiSeal fluid remains in placed at the desired location, forming a competent seal capable of resistingfluid crossflow from the formation before final in-situ crosslinking process occurs at a predicted time.

EquiSeal Conformance service > Stress-dependent(thixotropic) rheological properties

BENEFITS

» Allows precise placement of the gel system into the targeted area due to its stress-dependent rheological properties.

» Highly suitable for horizontal or highly deviated wells with different completion types such as openhole, slotted liners, OHGP’s and CHGP’s, among others.

» Wide temperature range of application, ranging from 140°F(60°C)to 250°F (121°C).

» Can be tailored for deep penetration into the formation or to bridge off at the formation face, as desired.

» Resistant to H2S, CO2, and acid environments.

» Predictable reaction time. EquiSeal provides a predictable and controllable crosslinking time (phase change from liquid to gel state) to obtain adequate placement. Treatment is insensitive to formation fluids, lithology, and/or heavy metals.

The Sealant Technology is the Key

EquiSeal Conformance sealant is based on a market proven polymer gel system combined with proprietary rheological modifiers. EquiSeal and EquiSeal NWB use an organically crosslinked polymer system that provides unprecedented sealant capabilities for controlling unwanted fluid production. Operator shave found that the organically crosslinked system is simply one of the most cost-effective polymer sealant systems available in the market. Combined with the rheological modifiers, EquiSeal and EquiSeal NWB Conformance services are game changers in the treatment of horizontal or highly deviated wellbores.

EquiSeal vs. EquiSeal NWB Conformance Services

Another versatile aspect of this service is that it can be formulated to allow for penetration into the formation matrix or to bridge off at the formation face for limited leakoff. EquiSeal is a solids-freesystem that can easily penetrate the matrix of the rock to have deep penetration. Conversely, EquiSeal NWB (near-wellbore)incorporates leak-off control additives in its formulation, to help provide a controlled and shallow penetration at the formation face.

Conformance treatment is placed with the aid of coiled-tubing and using packers to mechanically isolate the targeted area. EquiSeal optimum viscosity profile allows for an accurate placement of the treatment into the targeted zone.

石油圈

石油圈