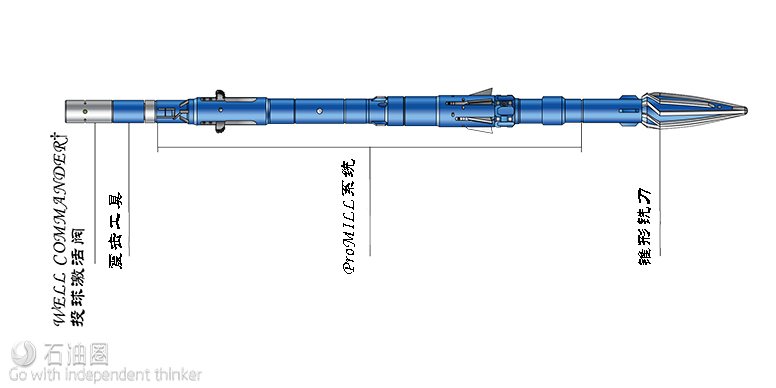

The ProMILL* trip-saving milling and underreaming system combines an underreamer and a section mill in one single-trip solution, achieving rock-to-rock zonal isolation and preparing the foundation for an abandonment cement barrier. Performing both operations in the same trip not only saves rig time and improves ROP but ensures plug integrity for confident P&A decisions.

Compared with perf-and-squeeze methods, the ProMILL system eradicates all potential leak paths—including channeling, microannuli, and mudcake—from the abandonment barrier, enhancing annular remediation.

Efficient section milling with rock-to-rock isolation

The ProMILL system’s section mill is a hydraulic downhole tool ideal for milling casing to set rock-to-rock well abandonment cement plugs. All cutter arms are dressed with tungsten carbide inserts (TCIs) that, along with the multiblade design, provide high ROP and maximum footage. ROP is optimized during prejob planning to ensure that swarf is produced at a rate consummate with surface swarf handling capabilities.

As pump pressure is applied, three cutter arms expand and begin the cutout. When the cutout arms are fully open, three additional cutter arms automatically expand into the milling position using a cam and ramp interface. The shorter lead arm opens slightly ahead of the longer follow arms, providing maximum force for the cutout. When all the arms are fully expanded, the cam reaches a flat interface, locking the knives open as long as a minimum pressure drop across the tool is maintained. All six cutting surfaces are then squarely sealed on top of the casing for optimal milling.

Each cutter knife incorporates chip-breaker ridges, and the continuous chip-breaker design generates steel cuttings with a size and shape that will not accumulate and block flow. These cuttings can easily be circulated out of hole, requiring a minimum of specialized mud conditioning.

Designed using the IDEAS* integrated drillbit design platform, the cutter inserts are engineered to minimize the size of milled casing shavings for optimal hydraulics without sacrificing milling speed. The IDEAS platform contains a database of casing material that catalogs the cutter performance and casing metallurgy to provide a clearer understanding of optimal milling performance and parameters.

Effective borehole enlargement fully controlled from surface

The ProMILL system’s underreamer is specially designed to meet emerging well-abandonment regulations. It is also ideally suited for enlargement of high-ratio boreholes in soft formations and can be used to ream short intervals in specific formations.

The underreamer features ball-drop activation, which ensures that the reamer remains inert during the entire milling operation. Once the window is milled, the BHA is repositioned with the underreamer at the top of the window. Then, a 1.5-in ball is dropped from surface to activate the tool; a pressure drop clearly indicates when the ball has raised the underreamer and has activated the tool. The section can then be underreamed, and the operator can continue to the target depth, completing the operation.

Circulating and mud conditioning

Operations are further enhanced with the WELL COMMANDER ball-activated drilling valve, which helps boost circulation to remove cuttings at strategic points in the drillstring. It allows conditioning or displacing wellbore fluids at high flow rates and enables bypassing sensitive downhole BHA tools with lost-circulation or wellbore-strengthening treatments with a simple, one-ball open-close functionality.

APPLICATIONS

■ Plug-and-abandonment (P&A) operations requiring rock-to-rock isolation

■ Remediation of annulus cement to remove microannuli, channeling, and other potential barrier failure modes

■ Large-diameter underreaming in soft formations

BENEFITS

■ Saves rig time by milling and underreaming in one trip and by requiring less BHA handling at surface

■ Improves ROP and hole cleaning during milling operations

■ Enhances operational efficiency and safety by eliminating barrier failure modes

■ Boosts efficiency through dynamic BHA analysis and modeling

FEATURES

■ Three expandable reamer arms that remain closed until activated and that fully collapse for retrieval through uncut casing

■ Ball-drop activation system ensures that the underreamer remains inert at all times during milling operations

■ Engineered cutting inserts developed based on laboratory optimization and development

■ Optional titanium-base blade treatment for section milling of chrome alloy tubulars

Case study

Efficient performance saves operator 3.5 drilling days and USD 600,000 in decommissioning operation in the UK sector of the North Sea

Efficiently mill and underream section in offshore well

An operator was planning a P&A operation in the UK sector of the North Sea. Its objective was section milling a 150-ft window in the 9?-in casing then underreaming the open hole—all in a single trip— to enable placing a rock-to-rock abandonment cement plug against the original formation.

Use integrated, single-run solution to achieve objectives

Schlumberger collaborated with the operator on an integrated solution that would meet the P&A objectives while decreasing the cost and regulatory concerns inherent to well decommissioning. The BHA solution included the ProMILL system with new performance milling inserts that feature a concave shape. The performance milling inserts were used in combination with the conventional inserts to enhance cutter durability and improve swarf quality. Additionally, the WELL COMMANDER valve was run to boost circulation by removing cuttings at high flow rates, which eliminated a dedicated trip for conditioning the wellbore fluids for the milling program.

The ProMILL system would eradicate all potential leak paths from the abandonment barrier which is not possible to ensure when using perf-and-squeeze methods.

Saved 3.5 days and USD 600,000 with single-trip solution

During milling, the operator achieved an ROP of 4.5 ft/h, representing a 50% increase compared with 3 ft/h, the average ROP of the operator’s jobs completed in the field. The knife wear on the ProMILL system was 30%–35%, which was lower than has been previously seen in similar operations.

The window was completed in 50 h, saving the operator 3.5 days and USD 600,000. This operation set Schlumberger records for the longest single-run window milling, section underreaming, and bridge plug setting as well as the longest single-run milled window.

ProMILL trip-saving milling and underreaming system helps save operator 7.5 rig days and USD 1 million as part of an ongoing abandonment operation

Efficiently mill and underream multiple sections in offshore well

An operator was planning a P&A operation in the UK sector of the North Sea. Its objective was section milling two windows of approximately 100 ft in the 13?-in casing—the first across the Frigg Formation and the second across the Utsira Formation. Each openhole section would then need to be underreamed—in a single trip—to enable placing a rock-to-rock abandonment cement plug against the original formation.

Use integrated, single-run solution to achieve objectives

Schlumberger collaborated with the operator on an integrated solution that would meet the P&A objectives while helping to decrease the cost and regulatory concerns inherent to well decommissioning. The solution included a hybrid ProMILL system cutting structure with new performance milling inserts used in combination with conventional inserts to enhance cutter durability and improve swarf quality. Additionally, the WELL COMMANDER valve was run to boost circulation by removing cuttings at high flow rates, which eliminated a dedicated trip for conditioning the wellbore fluids for the milling program.

The ProMILL system would eradicate all potential leak paths from the abandonment barrier which is not possible to ensure when using perf-and-squeeze methods.

Saved 7.5 days and USD 1 million across P&A operation

In the first window, across the Frigg Formation, the operator milled and underreamed a record-breaking 109 ft of 13?-in casing in one trip using performance inserts. In the second window, across the Utsira Formation, conventional inserts milled and underreamed 100 ft of133/8-in casing in 27.25 h, achieving the operator’s fastest milling time in the formation.

During milling, the operator achieved an ROP of 4.2 ft/h, representing a 40% increase compared with 3 ft/h, the average ROP of the operator’s jobs completed in the field. In this well, the operator recorded an overall cost reduction of 7.5 days and USD 1 million—the ProMILL system’s efficacy played an integral role in this achievement. Using the ProMILL system in this well continued the operator’s string of zero HSE events during abandonment in three previous wells.

石油圈

石油圈