AvantGuard* advanced flowback services optimize well performance from poststimulation operations through production startup. Ongoing, real-time monitoring ensures the well is being operated within a secure operating envelope to minimize risk of fracture and formation damage throughout the life of your well.

Bring synergy to fracturing, flowback, and CT operations

AvantGuard services bring synergy to fracturing, flowback, and CT operations enabling each operation to be performed while simultaneously accounting for requirements and results of other operations. The service applies to plug drillout and well flowback operations.

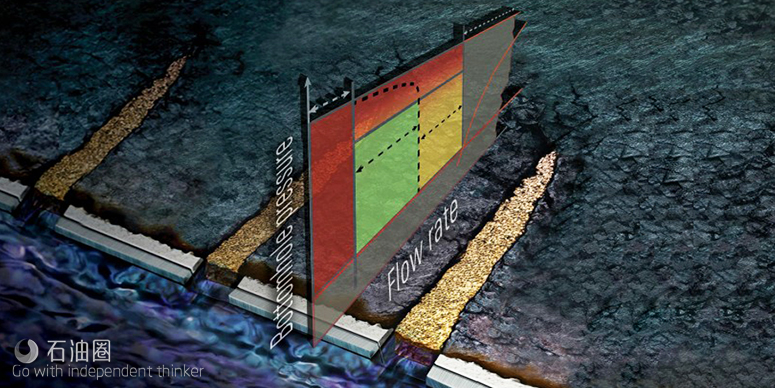

Continuously operate within the zone of stability

AvantGuard services are based on the application of the secure operating envelope, which is a combination of operational parameters that preserve the connection between hydraulic fractures and the wellbore. Operational parameters are defined from real-time pressure and production data, including solids production monitoring.

Changes in production rates are defined using the Vx Spectra surface multiphase flowmeter, which accurately captures multiphase flow dynamics in any flow regime for all fluid and solids types to enable real-time monitoring and analysis. The integrated dataset is used to characterize well performance and provide recommendations for a choke management strategy to preserve both the hydraulic fractures and the formation.

Minimize the risk of damage to the hydraulic fractures and the formation

AvantGuard services’ monitoring and analysis ensures the well is being operated within the secure operating envelope to predict and prevent fracture and formation damage compared with conventional rate transient analysis, which is used to identify postfracture impairment. This also ensures proppant flowback and solids production are minimized.

Operating within the secure operating envelope ensures connection to the reservoir is continuously maintained. Real-time well performance analysis enabled by AvantGuard services protects hydraulic fractures and minimizes formation damage. It also helps you diagnose, quantify, and prevent proppant production.

APPLICATIONS

■ Conducting well flowback and coiled tubing (CT) operations between postfracturing treatment and production

■ Securing well productivity by applying geomechanical modeling and real-time monitoring and control

■ Conducting high-frequency production, flowback, and solids monitoring

BENEFITS

■ Protects hydraulic fractures and formation stability

■ Preserves the connection between hydraulic fractures and the wellbore

■ Diagnoses early well behavior

■ Minimizes proppant flowback and solids production

■ Derisks scaling and precipitation issues

■ Secures investment for optimal NPV

FEATURES

■ Synergizes fracturing, flowback, and CT operations

■ Uses the robust Vx Spectra* surface multiphase flowmeter for real-time measurements

CASE STUDY

Optimize flowback operations and production in an unconventional reservoir

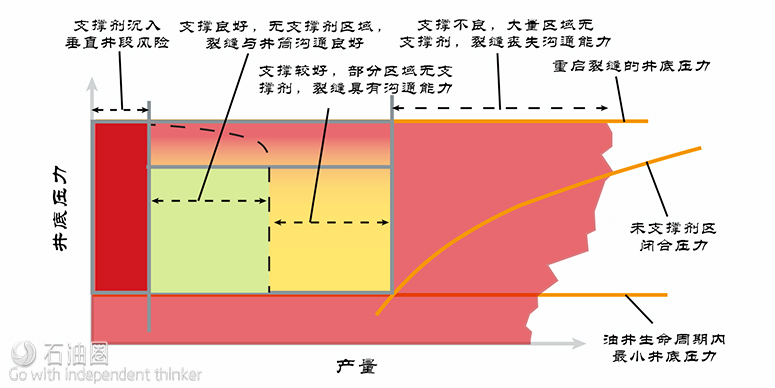

An important stage between the end of fracture treatment and the beginning of production is the flowback period. It usually involves high rates of drawdown imposed on the well to accelerate fracture fluid unloading, sand cleanup, and hydrocarbon production. If the flowback operation is not properly performed—taking into account rock and fluid properties—damage can be done to the formation, the fractures, or both. In this context, excessive proppant flowback from fractures presents a significant concern because it usually results in the creation of unpropped areas in the near-wellbore zone, which can easily be pinched closed later in the life of the well, leading to loss of the connection between the wellbore and the fracture.

While completing wells in the oil-rich Bone Spring sand in the Delaware basin, Devon Energy wanted to optimize flowback operations and mitigate potential fracture connection loss by minimizing the risk of uncontrolled sand flowback and near-wellbore fracture pinchout.

Integrate well and geomechanics data into advanced poststimulation flowback design

Schlumberger worked with Devon Energy to deploy AvantGuard advanced flowback services to develop a customized predictive flowback strategy based on choke management. Comprehensive welltesting data, including high-frequency fluid rates, sand rates, wellhead pressure, and solids and water samples, were gathered and analyzed for two of the operator’s wells in the basin.

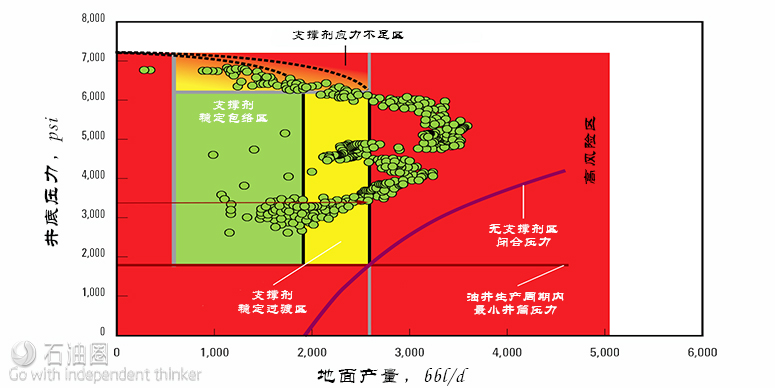

The results of Well 1 in the Permian basin in comparison with the modeled SOE indicated that rates were above the level of proppant pack stability.

The team proposed using the SOE approach to ensure preservation of connectivity between the hydraulic fractures and the wellbore during the lifetime of the well. The analysis revealed the following conclusions for the flowback operations conducted in Well 1:

■ insufficient effective stress on the proppant was applied at the beginning of the flowback operations

■ flow rates exceeded the limit for proppant pack stability at 2,000 bbl/d

■ rates were reached beyond the recommended SOE to create unpropped cavities near the wellbore

■ expected loss of fracture connectivity at bottomhole pressure less than 3,250 psi was due to closure of unpropped cavities, in turn limiting production performance.

AvantGuard Observe* flowback transient monitoring and analysis was used for real-time monitoring of flowback operations in Well 1, including the collection of samples of produced solids and liquids. Laboratory analysis identified that the solids returned to surface were proppant, and later samples contained smaller-size particles compared with earlier-acquired samples, indicating a certain degree of proppant crushing. These data were integrated in the design basis to propose a less aggressive flowback strategy that considered formation and fracturing design variables and changes in the proppant type to mitigate crushing potential for the subsequent wells.

Continuous solids monitoring by AvantGuard Observe monitoring and analysis detected changes in solids production over time.

The trend on the solids rate indicated an increase in continuous solids production at flow rates greater than 2,000 bbl/d, correlating with the SOE predictions. Further analysis of the SOE indicated that the maximum production rate of 3,580 bbl/min should result in the creation of unpropped zones, which may cause pinchout later during the lifetime of the well at a bottomhole pressure of 3,250 psi. This conclusion was later confirmed by rate transient analysis after a decrease occurred in the bottomhole pressure below the predicted level.

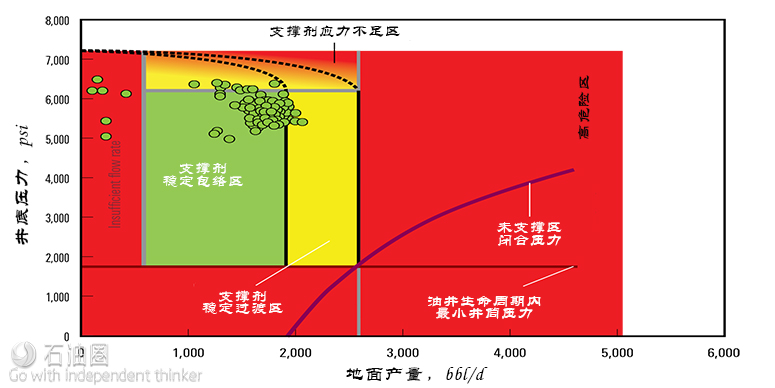

By following the customized AvantGuard services’ flowback strategy, the flow rates in Well 2 were within the SOE limit recommended for maintaining a long-term connection of the hydraulic fractures to the wellbore.

Make better-informed decisions on future wells

Based on the results obtained in the monitoring phase, Devon Energy changed the completion design of its subsequent wells to ensure that flowback operations were completed within the SOE outlined with Schlumberger. This considerably reduced the amount of solids produced, with only traces of sand detected at the beginning of flowback in Well 2 and none at the end of the operation, mitigating the risk of proppant conductivity damage and decreasing the risk of near-wellbore fracture closure.

石油圈

石油圈