Along-string measurements enable critical decisions, understanding of open, cased hole on structurally complex Norwegian North Sea field

With the development of a new field in the Norwegian North Sea, a major operator is taking on a complex task. The field was initially discovered in 1975 but proved too difficult to develop at the time. The field consists of an oil reservoir and several deeper, structurally complex, high-pressure gas and condensate reservoirs. Long horizontal wells are required for developing the oil reservoir, while several deviated wells will be drilled to unlock the gas and condensate reserves. Wells are drilled with restricted pressure windows and present a risk of both severe losses and influxes.

To support these operations, National Oilwell Varco (NOV) is providing real-time measurements from sensors embedded throughout the drillstring at regular intervals. NOV BlackStream along-string measurement (ASM) tools acquire temperature, annular pressure, rotation and three-axis vibration data at high frequency (256 Hz). The data is streamed to surface via the IntelliServ high-speed wired drill pipe telemetry network. The annular pressure is measured all along the wellbore at high frequency and is available in real time, with or without flow.

This is the first time such an extended data set has been acquired successfully and used in real time in the North Sea. As a result, the operator has been able to gather an improved understanding of the pressure distribution and fluid behavior along the open and cased hole. This has proven to be vital in the decision-making process.

Along-string Measurements

Downhole annular pressure-while-drilling (PWD) tools have been in use since the 1990s to help monitor and maintain the mud weight and equivalent circulating density (ECD) within safe limits. These tools are usually located in the bottomhole assembly (BHA) as part of the measurement while drilling/logging-while-drilling (MWD/LWD) tool suite. Only the condition of the hole at the bit is evaluated, and no more than a partial understanding is possible. Also, MWD/ LWD tools rely on mud flow to operate, and the information cannot be transmitted in low- or no-flow situations. This renders the drilling crew unable to detect significant events during, for example, tripping operations, connections, packoffs or losses. As a result, the industry has been relying on hydraulics models to assess what is happening along the length of the well, although these mathematical simulations are intrinsically limited.

The advent of NOV wired drill pipe (WDP) has enabled the use of distributed sensors measuring temperature, annular pressure, rotation and three-axis vibration data from multiple points along the drillstring. The WDP high-speed telemetry network is typically composed of:

• Downhole crossover to interface with third-party MWD/LWD and rotary steerable system tools, enabling bidirectional communications, to and from the BHA components;

• Wired drillstring components, including drill pipe, collars, jars and more, allowing for the data signal to be conveyed through the entirety of the drillstring at high data rates, up to 56,000 bits/sec (four orders of magnitude greater than the typical mud-pulse telemetry bandwidth);

• DataLinks – downhole network electronics subs that repeat, filter and amplify the signal along the string;

• A top drive data swivel that acts as an interface between the drillstring and the top drive; and

• The surface network controller – an interface to connect the drillstring network to surface systems.

NOV BlackStream ASM tools are integrated within the wired drill pipe network and embedded in the string at regular intervals. This gives the operations team a complete view of the drilling environment along the wellbore. The design is based on DataLinks – the signal amplifier subs were modified to include annular pressure sensors, as well as dynamics and temperature measurements. The tools are battery-powered and have the capability to acquire and transmit data to surface, independent of fluid and flow.

(Figure 1: NOV’s BlackStream along-string measurement (ASM) tools acquire temperature, annular pressure, rotation and three-axis vibration data at high frequency. The data is streamed to surface via the IntelliServ high-speed wired drill pipe telemetry network.)

The data from the distributed sensors is streamed to surface through the high-speed telemetry network, provided via wired pipe and fed into the rig data acquisition system (DAQ). Subsequently, the information is combined with surface data, such as block position, flow rate, etc, and real-time MWD/LWD formation evaluation data. By doing so, a detailed picture is obtained of the annular pressure trends along the open and cased hole. This enables timely and precise optimization of drilling parameters, fluid properties and section length.

Monitoring hole cleaning

Distributed along-string annular pressure sensors enable the real-time monitoring of the movement of material along the wellbore. This could be fluids, such as pills and sweeps or cuttings as discussed in the cases below.

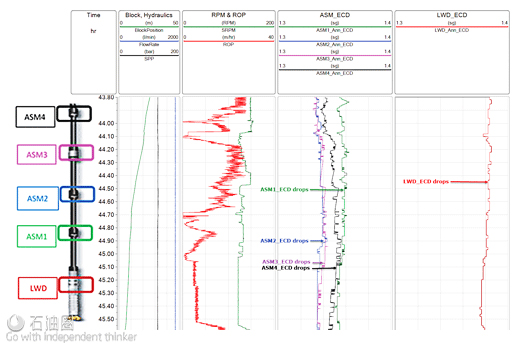

Figure 2 is a time-based log that shows surface parameters and ECD measured in several positions along the string while drilling a horizontal section in the challenging Norwegian North Sea field in October 2015. Flow rate was kept constant during a period in which a reduction in penetration rate was observed. ROP initially briefly dropped at 44.0 hrs; and, from 44.4 hrs, progress decrease is sustained. The diminution in ROP from around 82 ft/hr (25 m/hr) to less than 33 ft/hr (10 m/hr) resulted in a reduction in the amount of cuttings being generated and entering the annulus.

The plot shows that the MWD/LWD ECD (red line) values start to decrease quickly following the slowdown in penetration rate at around 44.45 hours. This is to be expected, as the measurement is being taken in the BHA and will be quick to respond to changes in the cuttings load in the annulus.

The annular pressure decrease can then be observed in the distributed sensors, starting with the lowest tool ASM 1 (green curve) at approximately 44.5 hrs and followed in sequence by the successive tools in the drillstring; ASM 2 (blue curve) at 44.9 hrs, ASM 3 (magenta curve) at 45.05 hrs, and the uppermost sensor ASM 4 (black curve) at 45.1 hrs.

The along-string sensors measure the cuttings load decrease, not simultaneously but in stages.

“The increased amount of data can also be overwhelming for real-time analysis… Displaying information in a smart way is of utmost importance when using such systems.”

Along-string sensors have also been of great help for assessing hole cleaning and annular fluid properties.

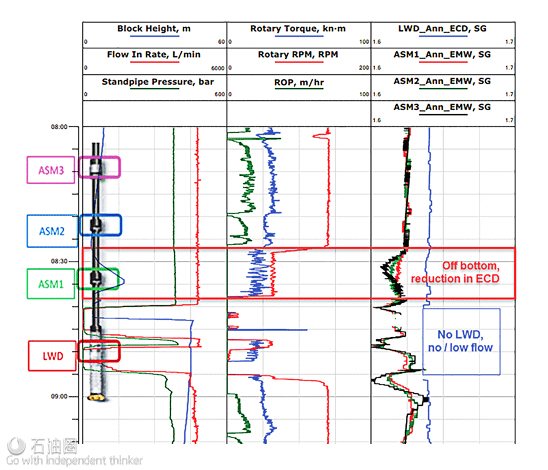

Figure 3 shows a time-based log with annular pressure measurements taken along the string over a connection event while drilling a low-angle section in February 2016.

At 08:30, stand down is reached, and one joint was reamed at reduced RPM and full flow rate. An instant reduction in ECD was seen in all sensors along the string. The largest drop is observed on the shallowest measurement tool along the string (ASM3_Ann_EMW, black curve).

There is no flow while making the connection between 08:40 and 08:55, and no data is transmitted by the MWD/ LWD tool. Therefore, the BlackStream ASM tools are the primary source of information. A reduction in equivalent mud weight (EMW) is seen. This corresponds to the transition from flowing to static mud, with cuttings settling down and friction loss due to pipe movement disappearing. Between 08:50 and 08:55, all along-string sensors show the same steady EMW figure, which can be interpreted as equivalent static density (ESD). This value is useful to check the actual downhole mud weight, assess effect of well temperature on fluid and confirm rheological models. It can also be an early indication of losses or influx.

At approximately 08:55, flow rate was staged back up. A rapid and short-lived EMW surge is measured by the along-string tools – this is the transition from static to flowing fluid, or mud gel break effect.

The EMW connection profile described above is most common when drilling at low inclination with bigger hole sizes.

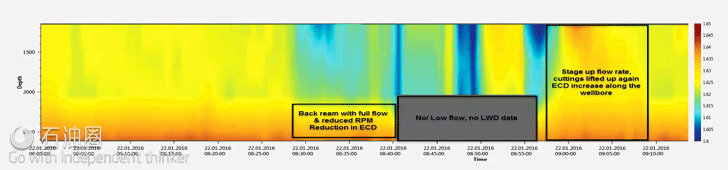

The amount of downhole data is greatly increased when using distributed sensors and wired drill pipe telemetry, which helps to improve decision making and provides the drilling team with enhanced knowledge. However, the increased amount of data can also be overwhelming for real-time analysis. To make full use of the information gained with real-time along-string measurements, close attention needs to be paid to the data transmitted and how it relates to the real-time operations. Displaying information in a smart way is of utmost importance when using such systems. For this reason, NOV has implemented an improved way to visualize EMW measurements acquired along the string using a heat map (Figure 4).

Figure 4: A heat map shows EMW measured along the string over same connection event as in Figure 3. The heat map is updated in real time, with new data being appended from the right-hand side. Measured depth is shown on the left-hand side, while an intuitive color scale is used to display equivalent fluid density.

The heat map is updated in real time, with new data being appended from the right-hand side. Measured depth is shown on the left-hand side, while an intuitive color scale is used to display equivalent fluid density (EFD). This enables an easy and quick understanding of the annular pressure distribution along the hole.

The along-string measurements help to visualize real-time hole cleaning and to adjust parameters, such as ROP, RPM and flow rate. Connection practices and circulation times are set as per what the well dictates rather than common practices. By viewing along-string measured EMW in a heat map, the observer is able to understand a complex data set at a quick glance.

Conclusion

The use of distributed annular pressure measurements in this field has increased the understanding of the downhole conditions and real-time hydraulics along the entire length of the open-hole section. High-speed, real-time equivalent mud density data has provided substantial value to the project by improving safety and performance. It has enabled the drilling team both at the rig and onshore to be more confident in their decision making. DC

石油圈

石油圈