电缆爬行器,是一种用于水平井或大斜度井的测井过程中,将测井仪器输送到预定位置的特殊工具,具有操作方便、工作效率高、使用成本相对较低的特点。本文对比了其与CT的优劣,介绍了其在高温高压水平气井修井作业中的成功应用。

来自 | Muhammad H. Al-Buali等

编译 | 白小明

在过去的几十年里,水平井钻井在油气工业中的地位正变得越来越重要,水平井可以有效钻达复杂的地质结构,开发边际油田,增加储层接触面积。在此期间,出现了一些用以解决水平井钻后修井问题的新技术。通常,当最大井斜为70°~80°时,重力辅助传输方法往往受到限制,而且该方法不适用于曲折的井眼轨迹。最终,在复杂井的大井斜段,需要使用连续油管(CT)爬行器和电缆(e-line)爬行器来将修井钻具组合下到位。

电缆爬行器技术已成功应用于沙特成熟油田的油藏监测以及向井内送入生产测井管串组合等作业。相比其他形式的传输方法,如CT,爬行器具有特别的优势。具体来说,爬行器可以用于具有复杂井眼轨迹的、采用裸眼完井的水平井,可以获得生产井和注水井的高质量流动剖面数据。

高温高压(HPHT)井钻井技术在沙特气田的应用,带来了水平井修井新的难题,包括但不限于使用爬行器下入射孔枪,传输较重的底部钻具组合(BHAs),以及在井底温度(BHT)大于300°F(149℃)的条件下进行作业。为了解决上述难题,需要改进技术并改变工具下入方式,以成功使用爬行器进行修井作业。

沙特致密气的开发

沙特的Ghawar油田富含大量的伴生气

Ghawar油田的Khuff地层为晚二叠纪、埋藏较深、非均质的白云质碳酸盐岩气藏,有两个主要的产层,即Khuff-B和Khuff-C。自20世纪70年代以来,已在Khuff-C产层开展了大量的钻井和开发工作,而更致密的Khuff-B产层近期才开始采用水平井钻井和完井工艺进行重点大规模开发。Khuff-B产层渗透率较低,气井需要采取酸化增产措施,使用多级桥塞-射孔方法,或者使用多级压裂尾管系统。关于该油藏的主要特点以及完井方式已有大量的描述资料。

该气藏地层的非均质性以及甜点位置的不确定性,意味着需要使用射孔的方式将长井段与储层连通,并采用增产的措施提高成功的可能性。种种因素表明,开发该气藏时所钻的这些井,在有很大挑战性的同时,非常适合采用爬行器进行修井作业,不过要想成功进行作业,有必要进行一些技术和操作方面的优化。

适用于沙特高温高压气田的爬行器技术

针对这些井,在设计使用电缆爬行器作业时,需要解决如下问题:

腐蚀环境

这些井高含硫化氢(H2S)和二氧化碳(CO2),必须采用特殊设计的由高镍合金制成的抗腐蚀电缆,H2S和CO2中等含量水平环境下需要耐温高达425°F(218℃)。与非酸性环境中所使用的电缆相比,这些电缆的一个重要缺点是其具有高的电阻抗。高阻抗不利于对于向井下设备传输电力,尤其是交流电(AC)。

更高的温度

随着油藏目标越来越深,爬行器必须能够承受300℉(149℃)至330℉(166℃)的高温,而且将来温度很可能会超过这一范围。

更长且更重的BHAs

与传统的油藏监测生产测井工具相比,使用的BHA(尤其是带有射孔枪的BHA)将更长更重。

从成功下入爬行器的角度来说,其必须满足以下目标:

1.能够在高温条件下可靠操作;

2.能够使用超长高阻抗电缆操作;

3.能够承受爆炸性射孔枪带来的高冲击载荷。

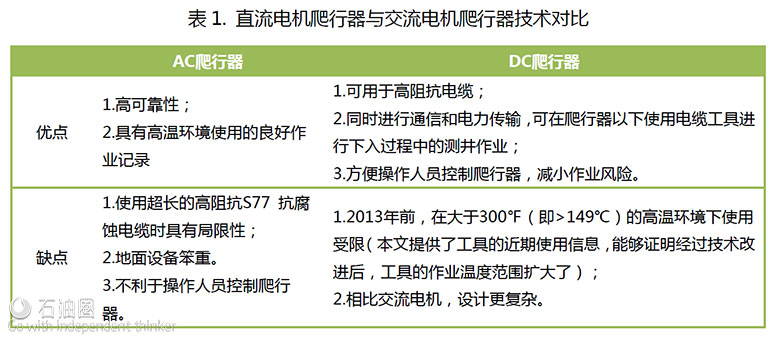

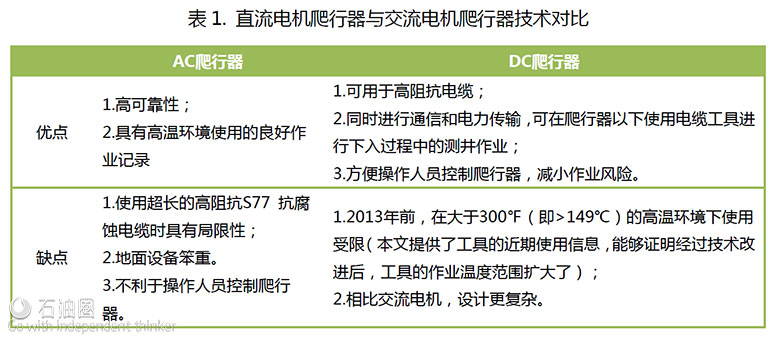

爬行器的核心是电机,其驱动液压泵为轮组提供动力,电缆爬行器可以使用AC或DC电机。虽然AC电机爬行器在高温环境下有着良好的使用记录,但是如前所述,它们不适用于腐蚀环境下使用的超长高阻抗电缆。

DC电机是用于爬行器更可行、更具操作性的选择,尽管其在高温环境下的使用记录有限;然而,在经过近期一些技术改进后,主要生产商将DC电机引入到爬行器的设计中,DC电机驱动的爬行器可以在更高的井眼温度环境下维持更长的操作时间,本文将介绍使用DC电机驱动的爬行器在井下的使用情况。

1.将抗冲击性引入到爬行器的工具设计和测试功效中;

2.在爬行器和射孔枪之间加入减震工具,以减小冲击;

3.根据使用状况进行维护,在爬行器返回实验室进行全面拆卸、维护和翻新之前,限定其传输射孔枪的趟数。

作业的可靠性

与其他井下电子技术的实施过程一样,使用爬行器时有三个主要因素影响其作业的可靠性:

1.工具的操作范围;

2.工具的有效性;

3.根据使用状况进行工具的维护。

Successful Utilization of E-line Tractor in Horizontal High-Pressure / High Temperature Gas Wells

Over the past few decades, horizontal drilling has become increasingly important to the oil and gas industry. It enables efficient access to complex structures and marginal fields, and horizontal wells increase the reservoir contact area. New technologies have emerged during this time to address post-drilling intervention challenges presented by such wells. Gravity assisted conveyance methods are generally limited to wells with maximum deviations of 70° to 80°, and they are unable to negotiate tortuous well paths. As a result, coiled tubing (CT) and electric line (e-line) tractors are needed to deploy bottom-hole intervention assemblies in complex wells with greater deviations.

E-line tractor technology has been successfully deployed in Saudi Arabia for reservoir surveillance, deploying production logging assemblies in wells in mature fields1. Tractors provide specific advantages as compared to other forms of conveyance, such as CT. Specifically, they can successfully negotiate complex well trajectories in horizontal open hole well completions, enabling acquisition of good quality flow profiles in both producers and injectors.

The application of horizontal drilling to high-pressure/high temperature (HPHT) gas fields in Saudi Arabia has introduced newer challenges to horizontal well intervention. These include, but are not limited to, operating tractors with perforating guns, Fig. 1, conveying heavyweight bottom-hole assemblies (BHAs) and performing jobs at bottom-hole temperatures (BHTs) greater than 300 °F. In response, the technology and deployment strategies have had to be enhanced to perform successful tractor interventions in these wells.

TIGHT GAS OPERATIONS IN SAUDI ARABIA

Ghawar field in Saudi Arabia is one of the world’s largest oil producing fields, Fig. 2, and has large associated gas reserves.

The Khuff formation in Ghawar field is a Late Permian age, deep, heterogeneous carbonate dolomitic gas reservoir with two major producing zones — Khuff-B and Khuff-C. The Khuff-C zone has been extensively drilled and exploited since the 1970s, while the tighter Khuff-B zone has only recently been the focus of an extensive development program with horizontal drilling and completion. Wells with low permeability in the Khuff-B undergo acid stimulation operations using a multistage plug and perforation method or using multistage fracture liner systems. Key features of the reservoirs and completions have been previously described.

The heterogeneity of the formation and the uncertainty of locating the sweet spots sometimes mean that long intervals must be connected to the reservoir with perforating charges to improve the likelihood of success with the stimulation operation. A combination of factors makes these wells a unique and challenging setting for performing well intervention with tractors, and the optimization of several technical and operational factors is necessary for interventions to be successful.

TRACTOR TECHNOLOGY FOR SAUDI ARABIAN HPHT GAS FIELDS

Planning e-line tractor operations in such wells requires addressing the following concerns:

- Corrosive environment: The levels of hydrogen sulfide (H2S) and carbon dioxide (CO2) in these wells mean that specially designed corrosion resistant e-line cables must be constructed from a high nickel alloy8 and then rated to 425 °F for medium levels of H2S and CO2. One important downside of these lines is their high electrical impedance, as compared to non-sour service wirelines. The high impedance can be quite obstructive to the transmission of electrical power — especially AC power — to downhole assemblies.

- Higher temperature: With deeper reservoir targets, tractor deployment must withstand 300 °F to 330 °F, and temperatures could possibly increase beyond that range in the future.

- Longer and heavier BHAs: The BHAs being conveyed — especially those configured with perforating guns — are longer and heavier than the more typical reservoir surveillance production logging tools.

From a tractor deployment standpoint, the tractor must be able to satisfy the following objectives:

- Perform reliably under high temperature conditions.

- Operate on long high impedance wirelines.

- Withstand the high shock loads that come with the explosive perforating guns.

At the heart of the tractor is the electric motor, which drives the hydraulic pump that supplies power to the wheels. Both AC and DC powered motors are used in e-line tractors. Although AC powered tractors have a good track record with high temperature operations, they are not suitable for operating on long high impedance lines like the lines required by corrosive environments, as previously described.

As shown in Table 1, the DC powered motors are a much more feasible and operationally viable option for tractor deployment, albeit with some concerns over their limited track record in high temperature operations; however, after recent technological advancements in these motors are incorporated into the design of tractors provided by leading providers, DC powered tractors can sustain extended operations at higher borehole temperatures9, and they were selected for operations in the wells described in this article.

AC Tractors DC Tractors

Pros Highly reliable

- Proven track record with high temperature operations ? Usable with high impedance cables.

- Simultaneous communication and power transmission, as well as capacity for logging down with the e-line tools below the tractor.

- Better operational control for the tractor operator, reducing deployment risk.

Cons Limited usability on long high impedance S77 corrosion resistant wirelines.

- Heavy surface equipment.

- Lack of fine control for tractor operator. ? Limited experience with high temperature(>300℉) operations before 2013(this article provides information about recent experience to demonstrate that the improvements have extended their range).

- More complex design as compared to AC powered motors.

- Incorporating shock tolerance into the tractor tool design and testing efficacy.

- Placing a shock absorption tool between the tractor and the perforating guns to reduce impact.

- Performing condition-based maintenance to ensure that tractors are exposed to a finite number of perforating runs before they are returned to the lab for comprehensive disassembly, maintenance and refurbishment.

未经允许,不得转载本站任何文章:

石油圈

石油圈