Halliburton has a new-generation acoustic analysis tool that uses hydrophone array technology to locate and describe communication paths and flow areas—vertically and radially in the wellbore area in real time. The array triangulates on the sound/flow source in or around the wellbore. Array analysis also helps eliminate false picks off of frequency and magnitude shows that have more to do with the well structure than the leak source. The radial locator has proven invaluable in some wells that have been logged by identifying which annulus or component of a completions system is leaking.

The ACX? service also reduces time by providing a continuous mode to quickly identify areas with possible leaks in the wellbore. In addition, it can accomplish stationary measurements to refine and reaffirm areas where leaks are identified by monitoring activity. Through post-run data analysis, the ACX service can provide the flow rate and phase estimations at the location of areas with possible leaks. In controlled testing, flow rates as low as 0.01 gpm have been identified. Field examples have also identified very low flow rates, which have been verified by customers.

The ACX service provides the following information:

Real-time data:

– Vertical location;

– Radial location;

– Frequency map;

– Acoustic magnitude.

Post-Processing reports:

– Flow rate degree;

– Phase type (liquid-gas);

– Flow mapping.

Advanced Processing

During the real-time capture, the surface data received enables quick on-site results. The ACX? tool additionally stores high-definition data internally that can be downloaded at surface and sent to the Formation & Reservoir Solutions group for advanced high-definition processing.

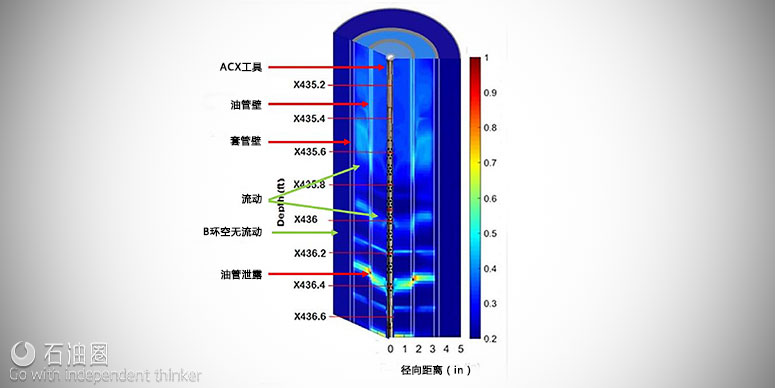

This data permits a closer examination of the flow and acoustic events around the wellbore. Flow mapping analysis can also be done with the data to create a map of the acoustic activity and present it in a 2D image that will show the flow path in the well.

The image to the right is a flow map that has been generated from the field log previously shown. The image illustrates a cross section of the wellbore with the tool in the middle. So as marked, the flow can be seen going through the tubing wall (Tubing Leak). Flow can be seen in the tubing and in annulus A (Flow), distinguished by the white mist coloring, while annulus B is dark blue indicating no flow observed (No Flow).

Cased-Hole Diagnostic Services

The ACX service was designed to be a part of a full suite of diagnostic services. It is combinable with production logging instruments, cement evaluation instruments, and much more.

Caelus Energy Alaska Avoids Costly Workover and Saves USD 3 Million

Caelus Energy Alaska had a well with a gas lift completion experiencing inner annulus (IA) to outer annulus (OA) pressure communication (95 psi/day OA buildup) when the IA was pressurized with gas. Because of the leak, the well could not be gas lifted, limiting production. Previous attempts to locate leaks in the field with ultrasonic leak detection technologies were unsuccessful, and efforts to solve this problem were abandoned. Halliburton proposed locating the leak using the Acoustic Conformance Xaminer? (ACX?) tool. The gas-only leak was activated by pressurizing the IA while bleeding pressure from the OA. The entire well was logged with the ACX tool, and additional stationary readings were taken at zones of interest. High-definition waveforms and flow map processing identified a shallow leak in the production casing hanger, while ruling out several zones of interest by using radial location, which is unique to the ACX tool. Since the leak was identified near surface, Caelus Energy Alaska plans to use a sealant repair method and avoid a USD 3 million workover operation. Another leak in a gas lift mandrel was remedied with a dummy valve, which was confirmed to be successfully repaired during a subsequent run.

A subsurface manager with Caelus Energy Alaska noted, “The new ACX technology will be invaluable to our organization to find small tubing or casing leaks, which previously we were not able to locate. Knowing definitively where the leak is provides us the best opportunity to perform a repair. Being in Alaska, our costs are extremely high, so reducing the amount of time diagnosing and repairing leaks has a large value to us.”

石油圈

石油圈