Enhancing management by exception

A key challenge to identifying abnormal well conditions is the consistent interpretation of real-time data. Even with experienced RTOs, it is sometimes difficult to completely remove subjectivity. Well teams are increasingly adopting an exception-based approach to well and field monitoring to improve operational efficiency, safety and decision making.

However, the effectiveness of an exception-based monitoring system depends on the number of false positives, which can cause distractions that result in missing important alerts. This issue is partly addressed by incorporating intelligence into the exception-based approach.

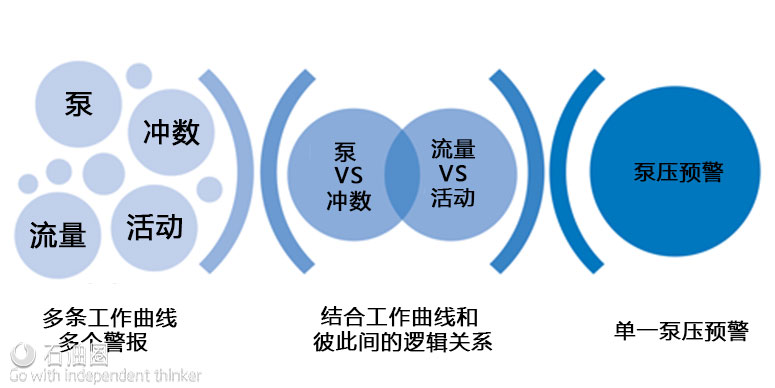

The alarm manager service combines several data sets to detect an event based on predefined logic. Figure 3 presents an example. Parameters such as pump pressure, pump stroke rate, flow-in and rig activity, combined with logic, can alert the RTO to an abnormal change in the pump pressure that was not caused by a change in operations.

By applying the same logic throughout, inconsistencies between the RTOs can be reduced. The alarm manager automatically triggers the right alarm to the right individuals at the right time and provides them with the documented knowledge to solve or mitigate potential problems. The HMI in the application presents visible and audible alerts and enables the RTOs to validate the alerts with log curves.

Figure 3: The alarm manager service combines several data sets to detect an event based on predefined logic. These data sets include pump pressure, pump stroke rate, flow-in and rig activity, to monitor for an abnormal changes.

Alarm management and human-machine interface

Based on industry experience, the user interface of traditional high-low alarm management applications is less than ideal for monitoring early kick detection at the wellsite or from a remote center. Raw data is often noisy, producing too many false positives that tend to overload the system and reduce the efficacy of real-time monitoring. The alarm manager service addresses this issue through multiple stages of signal processing.

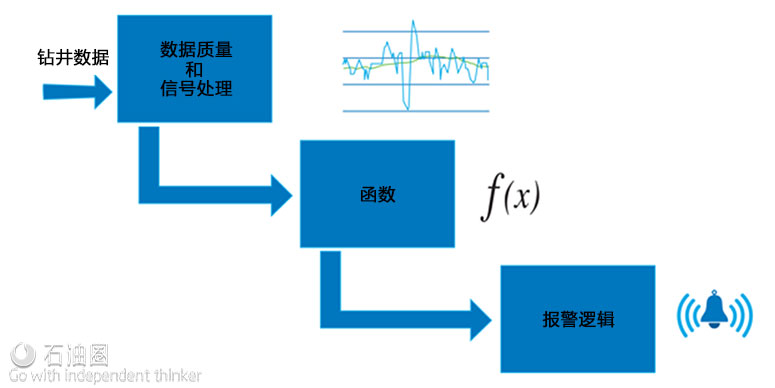

Figure 4: The alarm management process consists of three steps. First, raw well data is processed and filtered using dead-banding and outlier removal techniques. Second, the data runs through mathematical functions based on pre-defined alarm conditions. Lastly, the process uses logic to identify changing trends in the same way that a drilling engineer would.

The entire alarm management process consists of three stages (Figure 4).

In the first stage, to ensure data quality and reliability of interpretation by the RTOs, the raw data is processed using first-order filtering, dead-banding and outlier removal techniques to produce usable data without sacrificing accuracy. Data alignment techniques are applied to ensure data from various sources are accurately used in formula calculations. This ensures uniformity between the data indices, both time-and depth-based. Data gap processing techniques are applied to ensure the latest data are synchronized to provide accurate real-time outputs. If the data stream is interrupted, the functions that involve historical calculations are reset. The RTO can tune and adjust the degree of processing on a per-well basis.

In the second stage, a set of mathematical and custom functions based on pre-defined alarm conditions are used. Custom functions also can be created in a relatively short time using simple scripts. Analog data values are converted into a digital output or value change marker that indicates positive, negative, or no change. This approach makes it easier to compare changes in multiple parameters that are then used in the logic stage.

The application is designed with alarm logic that emulates the thought process of a drilling engineer. For example, the pump or SPP alarm looks at and trends the SPP changes as they relate to pump stroke rate (SPM). The alarm solution identifies changes in the SPP that are not consistent with the changes, if any, in SPM. The logic used in this alarm includes the rig activity, to avoid false alerts for pipe connections and other non-drilling activity, where SPP is not relevant.

The solution uses a modern non-relational database, which is designed for high-speed, high-volume data processing. This is a distributed database for managing large amounts of structured data across many servers. It provides high availability and performance, and scalability across multiple data centers. The application consumes many data formats, including the Wellsite Information Transfer Standard Markup Language (WITSML) data standard.

Operational example

In one major operator’s RTOC, the alarm manager system is being used to monitor data for a wide range of drilling parameters, including SPP, ROP, flow out and tank volumes. Alarm accuracy and consistency are measured periodically to determine the effectiveness of the system in identifying potential well control indicators. Alarms are tracked and grouped into four categories – alarm hits, alarm misses, alarm opportunities and not applicable. These are defined as follows:

- Alarm hit – A defined alarm sounds for an anomaly observed by the user.

- Alarm miss – An anomaly is observed but a defined alarm did not sound.

- Alarm opportunity – An alarm does not exist for this type of incident currently, but it would be useful to develop an alarm in this space in the future.

- Not applicable – An alarm is not required for this type of incident.

On one sample well, after the drillstring was pulled out of the hole, the well was flow-checked and observed to be static, which suggested there was no influx. One of three trip tanks was connected to the hole to ensure the annulus was always filled and to prevent any influx. The “Gains in Trip Tank” alarm activated after recording a gain of two barrels. This alerted the RTO, who acknowledged it and verified the gain using the real-time data, and then immediately contacted the wellsite using the escalation process and defined workflow.

The well was shut in and the pressures monitored while running in the hole to perform a successful well kill operation. The total initial influx before shut-in was less than three barrels. The ability to detect this threat at such an early stage enabled the rig crew to minimize the influx and prevent an escalation of the situation.

Results such as these have validated that the alarm manager service can effectively leverage real-time drilling data to help operators improve well control through quality assurance, 24/7 monitoring by experienced personnel, efficient human-machine interface, a reliable technology architecture, and robust communication workflows between the rig and remote center.

石油圈

石油圈