Alarm service applies algorithms that emulate an engineer’s qualitative thinking to leverage real-time drilling data, improve well control

By Nazaad Baksh, Anil Wadhwa, Baker Hughes

Industry statistics suggest that the majority of well control incidents and near-misses occur during well construction operations. To address this issue, the industry has focused on stringent well design and casing standards, blowout prevention equipment, safe drilling practices and multiple layers of workflows and controls. However, the data also shows that most well control incidents occur as a result of human factors – misinterpretation of data, delayed response to abnormal well conditions, drilling crew inexperience and physical fatigue – that are not addressed by hydraulics and mechanical well control mechanisms.

Baker Hughes has developed the WellLink Alarm Manager service, an exception-based, real-time remote monitoring solution using the company’s WellLink software platform. The service is being used as a monitoring and detection mechanism for early identification of well control events and prevention of serious and possibly catastrophic incidents. The alarm manager service offers real-time drilling surveillance and alarm management services that detect and notify remote operations teams of problematic trends and enable them to take corrective actions in a timely manner.

Data shows that most well control incidents are the result of human factors, such as misinterpretation of data, delayed response to abnormal well conditions, inexperience or physical fatigue. Exception-based monitoring of real-time data by remote operators can help reduce the risk of well control incidents resulting from human factors by increasing the operational awareness of drilling crews.

Built to the ANSI/ISA-18.2 Alarm Management Standard, the alarm manager service leverages advanced signal processing capabilities, sophisticated algorithms and notification mechanisms to detect potential drilling hazards, such as fluid influxes, at an early stage while filtering out false alarms and alerting the right people in time to mitigate the risk. The service helps operators scale drilling operations with fewer personnel using an exception-based and escalation workflow. Major oil and gas operators are using this solution to enhance the operational awareness of their personnel at the wellsite and in their remote operations centers (RTOC).

Real-time drilling data

Real-time data has long been used by major operators for drilling optimization and well placement activities but not so much for well control. One industry safety authority identified 29 types of causes that can result in well control incidents and categorized them as human, organizational and technological factors. Real-time digital data holds significant promise for addressing all three factors by increasing the operational awareness of drilling crews, who can use the data to take precise and proactive actions to minimize well control risks.

The severity and consequences of a well control incident depend on the rate and volume of influx, alertness and competence of the drilling crew, availability and condition of safety equipment, availability and reliability of real-time digital data, and the decision support mechanism. Surface logging services leverage drilling data acquired from downhole sensors to provide valuable information about well status and drilling performance to help drill wells more efficiently. Drilling parameters typically include flow rate, pump pressure, standpipe pressure (SPP), pipe rotation (RPM), weight on bit (WOB), rate of penetration (ROP) and pit volume (PVT). This surface logging data can also be used to monitor influx and mud losses. Through real-time monitoring, surface loggers can identify trends that may indicate the onset of formation fluid influx, and take appropriate actions.

Several challenges limit the way current real-time drilling data technology can be used. Real-time streaming data from a single well can consist of 50 to 500 data channels/tags, making simultaneous and continuous monitoring difficult. Current technology requires determining the well condition from single-curve plots and generic alerts. This technique is time consuming and leaves room for errors that can hinder interpretation, analysis and decision making by the well team. The real-time alarm service described in this article overcomes many of these challenges.

Overcoming organizational, human factor challenges

The push to manage more wells with fewer people at the wellsite presents numerous challenges from organizational and human factors perspectives. For example, surface loggers’ ability to effectively interpret the well condition depends on their competence level, the quality and reliability of real-time data, and the human machine interface (HMI). In many cases, the combination of lack of field experience, reliance on logs with data quality issues, and physical fatigue from continuously monitoring and assimilating real-time streaming data can cause the logger to miss important trends that could have provided an early indication of influx.

The real-time alarm service applies complex alarming algorithms that emulate the qualitative thinking of a highly experienced drilling engineer and converts that knowledge as the well is being drilled to improve decision making across the team. In this way, the software solution is enabling an elementary form of intelligence to augment the human intelligence at the wellsite and in the RTOC, improving how conditions are recognized; what the thresholds are for potential issues downhole; how the team will react or not react. The service can be customized to account for characteristics and behaviors that vary with well location and conditions. This enables the operator to apply variations in the alarm conditions while using the same basic algorithms to identify abnormal events. Subject matter experts can define new rules and calculations, or customize pre-existing ones, to fit the configuration of the well, the rig and drilling activities being performed.

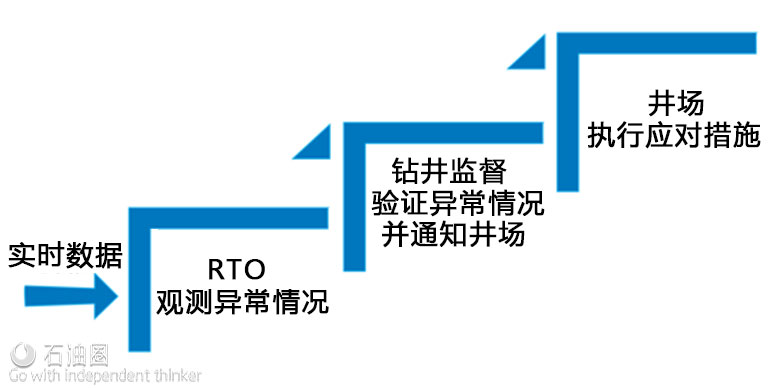

As illustrated in Figure 2, whenever an abnormal condition manifests itself in a well, the real-time operator (RTO) receives an alert and validates the well condition using various data logs. If the alarm is confirmed as positive and the condition warrants communication, the wellsite personnel are notified. The ultimate decision-making responsibility resides with the company representative or rig superintendent, who can now make decisions with confidence because they have full operational awareness.

When an abnormal condition occurs in a well, the real-time operator receives an alert and validates the condition using data logs. If the alarm is confirmed and the condition warrants communication, the wellsite personnel are notified. The ultimate decision-making responsibility resides with the company representative or rig superintendent.

石油圈

石油圈