Currently, oil & gas clients lose up to +/- 7% of total available production volume revenues due to inaccuracies in current measurement technologies. These current technologies include devices such as V-cones, the wedge and orifice plate meters – a technology more than 100 years old with an installed base of more than six million units.

The MPT is the first ultra-high pressure meter developed by Bell Technologies to address measurement in non-homogeneous situations where other flow meters fail.

The Bell Technologies, MULTIPHASE TORUSWEDGE (MPT) is a high-pressure flow meter for safely measuring multiphase volumetric flow rates for wellbore processes.

The meter is designed to provide high accuracy volumetric flow measurement on drilling rigs and can be used for multiple applications ranging from low to extremely high pressure. The MPT is particularly suited to mud flow where fluid is injected into the well through high-pressure high volume injection pumps. Mud is then returned to the surface through the bell nipple where it flows through the shaker for cleaning prior to being re-circulated back to the wellbore.

The product handles demanding applications that require robust performance combined with low maintenance. The MPT will allow operators to confidently monitor mud flow both in and out of the well and ensure long term asset reliability as well as safe operation of the rig.

The MPT mud flow meter is a primary flow element with a maximum pressure rating of 20,000 psi. It is designed to handle the higher flow rates and multiphase fluids that are typical in the drilling industry.

By monitoring the complete mud flow process, the rig operator will be able to safely control the

“Bell Technologies is currently working with a number of well service companies to develop a variety of mud flow solutions,” said Dave Bell, Owner & Chief Technology Officer of Bell Technologies, LLC. “This new meter is breaking boundaries for flow meters in high pressure applications where virtually every other technology has failed. It delivers value to our customers through more accurate measurement and reduced maintenance over traditional differential pressure and Coriolis technology.”

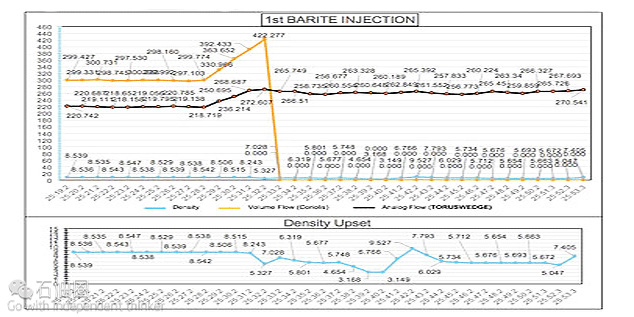

A third party test lab was used in November 2015 to provide test data to support the multiphase claim. The following graph provides data taken when multiphase conditions exist in a Coriolis being utilized for flow rate determination. The multiphase fluid was made up of water, Xanthan gum (carrier fluid), Barite, and air. All data and description of the mudflow system will be provided upon request.

Test Results: The graphs above show that the TORUSWEDGE continues to respond even through multiphase flow when other meters fail. Legend: Orange line is the Coriolis, Black line is the TORUSWEDGE. Blue line is the density of the fluid mixture.

The primary element used on the MPT is so effective, that Siemens (a global manufacturer of instrumentation) has partnered with Bell Technologies to provide a complete system that monitors mud flow more efficiently and improves safety on drilling rigs. “When coupled with a Siemens DP (differential pressure) transmitter and a PLC (Programmable Logic Controller) with proprietary software, this meter provides safe, reliable and highly repeatable performance with reduced maintenance in the toughest applications,” said Les Bottoms a senior Account Manager with Siemens.

Due to its improved accuracy over traditional meters, this device ensures more accurate measurement of the customers’ production revenues and improves customer cash flow by at least 3%. It has been proven to meet the demands of oil & gas customers for accurate, durable and cost-effective measurement across a wide range of applications. Unlike the orifice plate, it doesn’t wear out, bow, bend, or require replacement parts – therefore, lowering purchasing and maintenance costs by approximately 50%.

About Bell Technologies LLC

Bell Technologies, LLC, based in Houston, TX, is a global leader in helping businesses create and utilize innovative advancements in differential pressure flow measurement. The company combines technology and innovative engineering together to provide solutions to customers in industrial, commercial and consumer markets.

The mission of Bell Technologies, LLC is to become a primary source to industry for flow, density, mass, and viscosity measurement products. Product development originated with the TORUSWEDGE primary flow element and continues with future metrology products.

With its commercial goal to focus on upstream oil & gas applications and related process sectors where orifice plate meters are widely used and fall short of meeting client demands for performance and accuracy, Bell Technologies, LLC has created the solution to these flow measurement issues – the TORUSWEDGE primary flow element.

石油圈

石油圈