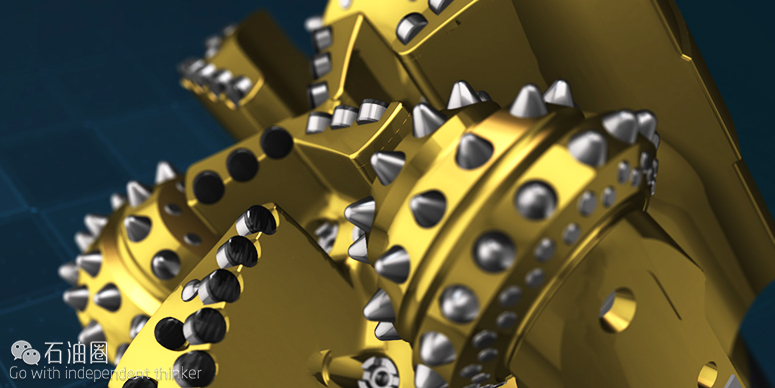

Baker Hughes announced today the commercial release of its line of Kymera™ XTreme (XT) hybrid drill bits, designed to help oil and gas operators lower their well construction costs through faster and more durable drilling performance. The bits—which combine the strengths of PDC and tricone bit technology—offer the smooth, consistent performance of previous generations of hybrid bits, while dramatically improving penetration rates and run life. Kymera XT drill bits are available in a variety of designs, each capable of addressing specific challenges in numerous applications, formation types and hole sizes.

The Kymera XT bits drill much faster than previous generation hybrid bits and offer a dynamic-balanced design that reduces torque fluctuations to minimize damage to the bit and, delivering efficient, effective performance in both vertical and curve sections. They also offer superior steerability and control in difficult environments, including carbonates and interbedded formations, in which conventional drill bits are often pushed to their limits.

The Kymera XT bits’ sharper, more durable cutting structures incorporate enhanced shapes and carbide grades for improved aggressiveness and accelerated penetration rates. These advanced designs provide added tool face control, enabling the drilling of longer distances at higher buildup rates than was previously possible, while maintaining a high-quality borehole throughout extended runs. Blade and roller cone designs can be optimized based on the operator’s application to deliver a variety of benefits that include long, section-to-section runs and enhanced durability during transitions between formations.

“Kymera XTreme hybrid bits combine the control and rock-crushing strength of a tricone bit with the speed and shearing action of a PDC bit and, in almost every case, are more durable than either of the alternatives,” said Scott Schmidt, Vice President, Drill Bits at Baker Hughes. “This combination delivers a bit capable of drilling longer vertical and curve sections at higher speeds and in a variety of challenging formations – an extremely valuable tool to help our customers effectively manage their well construction costs in this challenging business environment.”

In one recent Middle East application, a Kymera XT hybrid drill bit demonstrated superior durability by drilling 2,721 ft (829 m) of extremely hard and abrasive series of limestone, sandstone, and shale formations in one fast run—improving rate of penetration by 138 percent over the field average and reducing the operator’s cost-per-foot by 50 percent. As a result, the operator finished the section 2.3 days ahead of schedule, saving nearly USD 100,000.

The Kymera XTreme hybrid drill bit is the latest example of Baker Hughes’ strategy to improve well efficiency, optimize production and increase ultimate recovery.

Location: Middle East

An operator working in a prolific field in the Middle East wanted to streamline and expedite development of the field. The operator typically drilled challenging interbedded sections using tungsten carbine insert (TCI) roller cone bits with an average ROP of approximately 38 ft/hr (11.5 m/hr), but believed it was possible to drill faster, mitigate torque fluctuations, and improve their cost-per-foot.

Baker Hughes recommended the Kymera™ XTreme (XT) hybrid drill bit for the application. Building upon the success of prior hybrid technology, the Kymera XT bit can be customized for each scenario and delivers smooth, reliable, faster, and more durable drilling performance in both vertical and curve drilling applications. It also delivers superior tool-face control in difficult drilling environments including challenging carbonates and interbedded formations where drilling speed and durability are often pushed to their limits. The Baker Hughes DART drilling application review team analyzed the formation properties through the difficult section and then customized a Kymera XT bit to perform optimally through that section. The BHA was also modeled and customized to achieve high performance and improved torque response with the Kymera XT bit. The DART team then performed a detailed formation drilling analysis to forecast how drilling performance would be affected by the Kymera XT hybrid drill bit.

The Kymera XT bit was deployed downhole and successfully drilled the 4,800 ft (1463 m) section in a single run, eliminating the bit trip that had been required when the operator used roller cone bits. The bit achieved the highest average ROP in the field. A rig-specific comparison on four wells revealed an ROP increase of 126%, more than doubling the field’s average and exceeding the operator’s previous field-wide benchmark by over 20%. The increase in ROP saved 2.5 drilling days and the Kymera XTreme hybrid drill bit delivered the smooth torque response and improved drilling efficiency that was crucial to the operator.

Location: Middle East

A major operator working in the Middle East was experiencing well loss challenges when drilling through a difficult interbedded section. The 16-in. section, which comprised limestone, sandstone, and shale formations, was extremely hard and abrasive. To minimize the risk of losses, high-weight mud was used, but this significantly reduced ROP and the operator needed to use two tungsten carbide insert (TCI) roller cone bits to complete the section. The operator had then tried to improve ROP through the section by using PDC bits, but without success. Concerned about this drilling cost and, believing it was possible to drill the entire 2,721 ft (829 m) section, shoe-to-shoe, in one run, the operator asked Baker Hughes for a solution.

Baker Hughes recommended the Kymera™ XTreme (XT) hybrid drill bit for the application. Building upon the success of prior hybrid technology, the Kymera XT bit can be customized for each scenario and delivers smooth, reliable, faster and more durable drilling performance in both vertical and curve applications. It also delivers superior tool-face control in difficult drilling environments including challenging carbonates and interbedded formations where drilling speed and durability are often pushed to their limits.

After Baker Hughes collaborated with the operator and designed a customized Kymera XT bit for the challenging section, the bit was deployed in the well. The Kymera XT bit drilled the entire section in a single run, eliminating the cost of a bit trip and a second bit that the operator had incurred on previous wells. Drilling through the 16-in. section proceeded with 138% higher average ROP than the field average, and 50% lower costs per foot than the rollercone bits had delivered in offset wells. As a result, the operator finished the section 2.3 days ahead of time and saved nearly USD 100,000.

石油圈

石油圈