Multistage Unlimited Frac Isolation on Coiled Tubing

NCS Multistage developed Multistage Unlimited technology as a more efficient and more economical alternative to plug-and-perf and ball-sleeve frac systems, both of which bullhead fluids down the casing, with no feedback about formation response at the frac zone, no recourse in the event of a screenout, and no way to manage water and chemical consumption. Both methods do, however, have a big appetite for pumping horsepower.

The coiled tubing solution

In developing Multistage Unlimited technology, NCS faced two challenges:

overcome the limitations of one-way fluid movement

find a more efficient way to isolate each stage during completion

NCS overcame both challenges by adopting coiled tubing to operate the Multistage Unlimited frac-isolation system and to open the company’s GripShift casing sleeves.

The coiled tubing work string provides a circulation path to the frac zone and also allows the use of a unique resettable frac plug that can be repositioned to isolate each stage for stimulation. Current coiled tubing capabilities are more than adequate to handle multistage completion operations. Already, more than 12,300 miles of coiled tubing runs have been executed to complete more than 130,000 stages.

Circulation vs one-way fluids

With the ability to circulate or reverse circulate during completions, Multistage Unlimited systems offer more operating control:

Acid and other leading-edge fluids can be circulated down to the isolated zone before frac pressure is applied, with returns back up the coiled tubing

Screenouts are less likely and can be quickly removed, allowing more aggressive sand loading.

The coiled tubing is open during fracs, to monitor formation response at the target zone in real time, allowing sand placement to be optimized.

Sand-jet perforating can be used to access the formation, to add stages in blank casing when running the Multistage Unlimited casing sleeve system

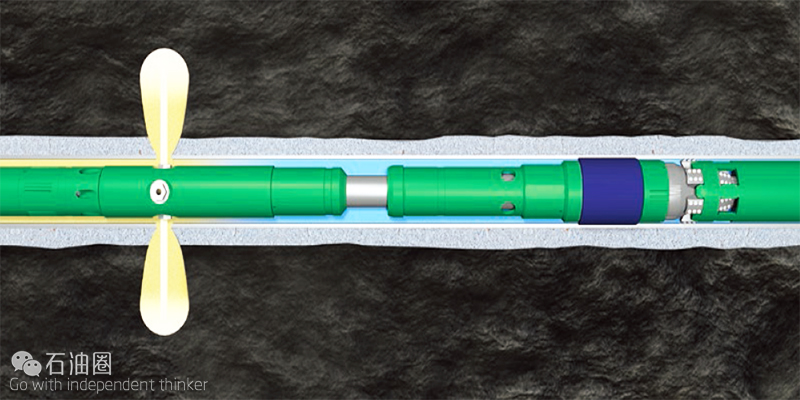

Coiled-tubing-operated, resettable frac plug

The Multistage Unlimited resettable frac plug eliminates the need for composite frac plugs, which have to be run and set at every stage and drilled out before the well is put into production, and ball-seat casing sleeves that cause real problems when they don’t shift and also restrict the wellbore. With the Multistage Unlimited resettable plug, there is nothing to run in the well between fracs, nothing left in the well and nothing to drill out; just a full-open, production-ready wellbore.

The Multistage resettable frac plug resembles a conventional resettable bridge plug, but it is engineered to operate reliably in a sandy environment. Pulling it up through clean fluid a short distance completely flushes any sand or proppant from the tool, leaving it ready to set at the next stage. A simple j-slot mechanism operates the plug with straight up-and-down coiled tubing movement.

The engineered-elastomer seal contains differential pressure up to 8,500 psi, well above typical formation breakdown pressure and temperatures up to 350 °F.

Casing sleeves or sand-jet perforating

To gain access to the formation for the frac, Multistage Unlimited systems use either GripShift casing sleeves or Mongoose sand-jet perforating. The sand-jet perforating sub run as part of all Multistage Unlimited frac-isolation assemblies. For completions with casing sleeves, the sand-jet sub can be used to add stages in blank casing, without tripping out of the hole. For completions without casing sleeves, sand-jet perforating is used for all stages.

GripShift casing sleeves are shifted by setting the frac plug in the inner sleeve, then applying pressure above the seal. The inner sleeve shifts downward, opening frac ports at the top of the outer sleeve, and the frac is pumped down the coiled tubing annulus. This shifting method has proven much more reliable than ball-drop sleeves.

For sand-jet perforating, the frac plug is set to isolate the target zone. Then an abrasive slurry is pumped down the coiled tubing and through the sand-jet sub to cut perforations through the casing and cement and into the formation. After perforating, which takes about 8 minutes, the frac is pumped down the coiled tubing annulus.

The Half-Straddle for low-rate fracs

In formations with thin reservoirs and water-bearing zones nearby, it is usually best to complete with a large number of stages and smaller fracs to avoid the water. These smaller fracs—typically 10 bpm or less—can be pumped through the coiled tubing, making it easy to control frac height. It’s called the Half-Straddle casing-sleeve option, because it resembles a coiled-tubing straddle with only a lower seal (the resettable frac plug), while the upper seal is achieved by closing the annulus at the surface during the frac.

Whenever the Half-Straddle option can be used, it provides three important advantages:

• It reduces water consumption even more—up to 50% compared to plug-and-perf and ball-sleeve systems.

• Low frac rates and volumes help control frac growth.

• There is no need for a high-pressure wellhead stack because the coiled tubing contains all frac forces.

Situation

An operator in the Cleveland Sands of the Anadarko basin had been using open-hole packers and ball-drop sleeve technology for all completions, until a plug-and-perf trial was prescribed in a quest for better production results. With plug-and-perf, however, the cost and efficiency exceeded their current model with only a small uptick in production. The operator then looked for other completion alternatives.

Challenge

The operator sought to gain better production while also improving operating efficiency and maintaining or lowering cost.

Solution

The operator performed a multi-well test using Multistage Unlimited cemented casing sleeves and the Multistage Unlimited coiled-tubing frac-isolation completion assembly.

Results

After the trial, about 400 sleeves per month were being installed, with multiple stimulation and coil crews following. The learning curve for all parties—NCS Multistage, coiled tubing, and pressure pumping—was steep, but short. After only a few wells, the completion team was in “factory” mode. In a very short time, NCS had installed and fracced 600 sleeves with a success rate greater than 98%. In addition, completions averaged 12 stages per day, compared with 6 stages per day with plug-and-perf. Multistage Unlimited system delivers production uplift of more than 30% in the Anadarko basin

The operator published the following reasons for continuing to use the Multistage Unlimited system:

• Only method that provides verifiable high-density, independent fracs;

• Verifiable stage isolation;

• Better long-term wellbore optionality;

• No operation limits on stages;

• Deployment as planned.

石油圈

石油圈