In a challenging economic environment, the industry is focused on making unconventional assets economical and sustainable at low commodity prices. The formula for success to reduce cost per barrel of oil equivalent (BOE) is to increase recovery to meet production targets while drilling significantly fewer wells.

Such results are possible with Halliburton’s ACTIVATE refracturing service, a collaborative workflow that leverages subsurface insight expertise and breakthrough technologies to help operators recover bypassed reserves predictably and repeatedly at one-third the cost of a new drill.

ACTIVATE service enables operators to build a balanced portfolio of new wells, infills, and refracs – thereby allowing reduced breakeven point of their unconventional asset and increased bookable reserves.

In basins where we’ve delivered the ACTIVATE Service, operators have seen up to:

80% increase in estimated ultimate recovery (EUR) per well

25% increase in oil recovery factor with balanced portfolio

66% reduced cost per BOE compared to new drills

Learn how Halliburton can help you confidently recover bypassed reserves and maximize the profitability of your unconventional asset at the lowest cost per BOE.

Breakthrough technology helps recover what gets left behind in the reservoir

Recent advancements in engineering technology and subsurface insight processes indicate that, historically, fractured wells have left significant recoverable reserves in the ground – often because of poor cluster efficiency, unequal fracture lengths, and loss of fracture conductivity. In fact, two-thirds of stages decline early during the life of a well, resulting in only a 4% to 8% oil recovery factor.

As a result, we routinely leave over 92% of reserves in the ground – completely untouched! This means that there is a huge potential to refracture thousands of wells over the next few years. This potential represents reserves that could be recovered more predictively and repeatedly with innovative technologies and subsurface expertise.

Recover bypassed reserves predictively and repeatedly

Wells with bypassed reserves frequently fall into one of three main categories. Wells that have been understimulated. Wells that have lost connectivity to propped fractures. And parent wells that are at risk to lose production once an offset child well is stimulated. So how do we go after those reserves?

With ACTIVATE service, our four-step process delivers repeatable and predictable refracturing results. Our service takes operators through a journey from a refracturing pilot to an optimized large scale refracturing program. This allows operators to build a balanced portfolio of new wells, infills and refracs.

Step 1 – SCREEN the best candidate wells.Through a fast, nimble, and transparent process, Halliburton’s local tech teams collaborate with you to select candidate wells with the best reservoir quality and non-optimized completion quality. We also perform well spacing impact analysis to determine which wells may be negatively impacted by the refracturing process, and incorporate a well bashing mitigation plan.

Then, we take the top-ranked wells and perform an incremental estimated ultimate recovery (EUR) and economic development payback analysis, using reservoir and economic models. We also evaluate the wells’ mechanical integrity, to determine if they can be subjected to high pressures during restimulation. Our goal in this stage is not just to come up with one good well for refracturing, but to also measure our success at a multi-well pad level to better ensure that we can increase the recovery factor of the whole pad.

Step 2 – DESIGN tailored refracture treatments and placement of new perforations. We focus on each well separately to determine how much of the reservoir still needs to be stimulated in its second life. If additional perforations are needed, FracInsight service gives us the ability to evaluate rock quality across the entire lateral and to place new perforations in strategic locations that have indicated the best fracability and productivity index.

Using AccessFrac stimulation service we tailor our design to focus on the target zones where the new proppant needs to be delivered in order to help maximize lateral coverage and total stimulated reservoir area.

Step 3 – EXECUTE the refracture treatment, aimed at full lateral coverage. This step starts with wellbore preparation to evaluate how much of the wellbore has already been pressure depleted. Pressure-depleted areas are then bridged off, leveraging our proprietary Pressure Sink Mitigation (PSM) process, so that proppant targeted to create a new frac will avoid those pressure-depleted areas and go where it should go.

After preparing the wellbore, we refracture the well with AccessFrac service. The first set of diversion cycles reconnect the wellbore to propped fractures where conductivity was lost. The next set of diversion cycles generates new fractures from either the old perforations that were not stimulated in the first life of the well, or from the newly added perforations for the second life of the well. This combination of newly connected and newly created fractures produces the incremental stimulated reservoir volume. It’s this combination that helps increase EUR.

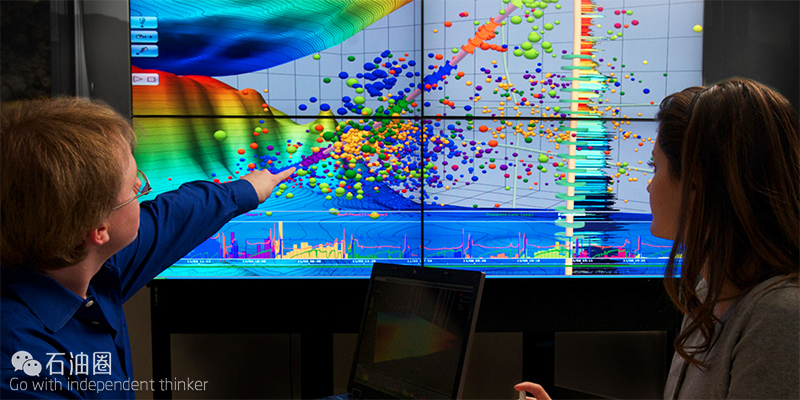

Step 4 – DIAGNOSE refracture efficacy and optimize refrac design for future pads. Real-time monitoring using microseismic or microdeformation data shows us if every AccessFrac diversion cycle is actually moving fluid along the lateral. If not, we can adjust and correct this by modifying the process controls of AccessFrac service in realtime. We are also able to use FiberCoil tubing in the offset lateral to monitor and help mitigate well bashing.

Post-frac, we use FiberCoil tubing to not only clean the wellbore, but also to measure stimulation effectiveness at a cluster level. During production, we close the loop with FiberCoil tubing by performing a lateral contribution log, so we can validate if the new fractures are adding to the production of the well in its second life. The integration of subsurface insight from the pilot pad allows us to take the learnings from the pilot and calibrate our reservoir model.

Lastly we leverage our calibrated model to perform design sensitivity scenarios to predict EUR for future potential refracs. We finally develop a large-scale refrac field development plan for that specific acreage.

石油圈

石油圈