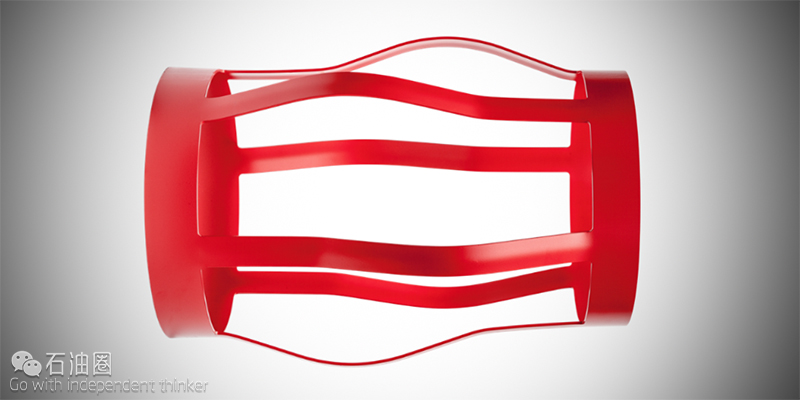

With innovative single-piece construction, premium steel alloy, and jigsaw joints, Centek’s UROS-CT centralizers contribute to greater well productivity by ensuring an enhanced cementation job in deepwater wells.

As leading innovators in centralizer design, Centek understands the need for a close tolerance centralizer for use in tight annulus applications, where narrow margins between pore pressure and the fracture gradient exist. In deepwater operations centralizers must compress virtually flat to allow travel through a series of tight casing strings but still be capable of expanding to the designed open-hole size.

The endbands (or rings) on the UROS-CT are manufactured to very tight tolerances where the ID of the centralizer is only 0.030 in. over the maximum casing OD. They are also manufactured with far superior roundness and ovality which allows for closer hugging of the casing and more importantly, less offset abutment with the contacting pad.

The UROS-CT is designed with a precisely formed cross bow curvature so there are no “knife edges” (common among standard bow spring centralisers) as the bows are inserted into a subsea well head or supplemental adapter in deepwater drilling operations reducing the risk of subsea well head damage. This also adds additional strength to the bows.

The UROS-CT’s rugged, single piece design ensures no point loading of a single bow (common among welded/integral lock bow spring centralizers) occurs during RIH. The UROS-CT evenly distributes the axial and radial loads throughout the entire unit as they are applied during close tolerance casing running operations.

Centek’s UROS-CT patented design dramatically reduces initial insertion, start and re-start forces when entering a narrow annular restriction or previously set casing (including expandable casing or liner ID’s) while providing maximum stand-off in under-reamed OH sections.

The UROS-CT

Designed to challenge the traditional and extremely costly centralizer sub market.

Provides maximum stand-off in tight annulus applications.

Engineered to precise ring-gauge tolerances, because every millimeter saved allows for greater expansion in the open hole.

Low-profile design provides peak flow-by performance to reduce the surge effect common with narrow annular clearances as well as reducing ECD signatures.

Applications

Deepwater

Tight casing tolerances

Highly deviated wells

UR Wells Sections

Horizontal/ERD wells

Vertical-Wash Out Sections

S-Type/J-Type

Case study

NORWAY, DEEPWATER

Customer makes UROS-CT the preferred choice to replace subs for their deepwater wells in Norway

Region: North Sea Country: Norway Type: Deepwater Field: Ekofsk

THE CHALLENGE

A customer in Norway needed a centralizer package suited for a specific close tolerance operation in a deepwater well with a total depth of 9,778 TVD RKB ft and 16,614 MD RKB ft.

The desired solution had to provide a reduced insertion force and low running force, tested and proven in the restriction; along with suitable standoff and a high axial stop collar load capacity – all at a low cost to meet close tolerance capabilities. For this specific well the customer needed to run a 17″ liner through a wear bushing restriction with an ID of 17.75″ to 3,295 ft TVD. The high cost centralizer sub would be the traditional close tolerance application for this type of well.

THE SOLUTION

To meet the challenge Centek, Halliburton and Ace Oil Tools recommended the Centek UROS-CT centralizer and the Ace Ratchet Collar.

The UROS-CT close tolerance centralizer is specifically designed for use in tight annulus applications where narrow margins between pore pressure and the fracture gradient exist. In deepwater operations the UROS-CT can compress virtually flat to allow travel through a series of tight casing strings but is still capable of expanding to the designed open-hole size.

In this instance the UROS-CT was used in conjunction with the Ace Ratchet Collar provided by Ace Oil Tools. This stop collar contains high axial load capacity along with a slim design (4.1mm WT). The stop collar consists of two parts which are pushed together and locked in place with a ratchet mechanism. It is easy and fast to install and will give an axial holding force of 103,000 lbs in this particular design and size.

THE RESULT

By using the Centek UROS-CT centralizer and the Ace Ratchet Collar in combination all of the requirements from the customer were met and the 17″ liner safely passed through the tight restriction without issue.

This combination is now the preferable solution for this type of application in the North Sea

About Centek

Centek specialises in delivering innovation, design and engineering expertise to casing centralization in the Upstream Oil and Gas industry.

Centek units are manufactured to NQA standards BS EN ISO 9001:2008. They are also API 10D No. 0022 certified. We have received industry recognition in the form of two Queens Awards. The first was presented to us in 2008 for enterprise and the second in 2009 for innovation.

石油圈

石油圈