As we all know, regulatory mandates, environmental stewardship, and HSE best practices all demand gas-tight, V0-rated well isolation.

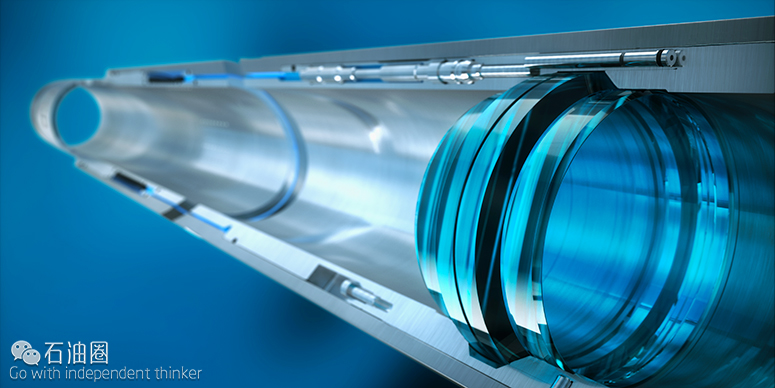

Baker Hughes STONE WALL V0-rated well barriers deliver reliable, safe wellbore isolation.

No matter your operational needs, this portfolio of gas-tight mechanical well barriers has you covered:

- Temporary isolation during drilling;

- Short-term suspension for workovers;

- Wellbore isolation in extreme HP/HT environments;

- Permanent seal during well abandonment.

Whether you are drilling, completing, producing, or abandoning your well, the STONE WALL V0-rated well barrier portfolio delivers a suite of tools to confirm mechanical wellbore isolation for all of your operational needs. Each barrier undergoes a stringent testing process to ensure it is validated to ANSI/API 11D1 ISO 14310 V0 standards, helping ensure total well control, enabling safe operations, and protecting the environment.

Obtain reliable temporary well suspension

CROWNSTONE GTV Tubing-Retrievable Well Barrier Ensures a reliable gas-tight seal for temporary isolation.

Wellbore temporary suspension requires ft-for-purpose products that are reliable, comply with stringent regulations, and provide well control. Baker Hughes has developed a well barrier that ensures the well is isolated and that the integrity of the wellbore is protected.

The CROWNSTONE GTV tubing-retrievable well barrier is qualified as a gas or bubble tight barrier according to the V0 acceptance criterion, defined by the ANSI/API 11D1 (ISO 14310 Third Edition). This retrievable well barrier can be tested from both above and below the production zone with the use of the LT-CT retrieving head. The CROWNSTONE GTV enables well control through the drill pipe during the pressure equalization across the well barrier. The LT-CT retrieving head has a telescoping milling shoe that is used to retrieve the barrier when sand and/or debris on top of the barrier is anticipated. The LT-CT retrieving head is also used when well control is desired through the drillpipe by allowing complete washing to the top of the barrier, stopping communication between the drillpipe and annulus.

The barrier is designed as a long-term abandonment well barrier. Long-term is defined by the length of time in the well, varying from 1 to 18 months. This time period starts when the well barrier is set until it is retrieved.

The CROWNSTONE GTV barrier is part of the Baker Hughes STONE WALL V0-rated barrier portfolio—a comprehensive suite of tools that ensures gas-tight isolation throughout the well’s lifecycle.

Applications

- Casing evaluation;

- Repair and testing of wellhead or B.O.P;

- Riserless well integrity testing;

- Wellbore temporary suspension;

- Hurricane plugging.

Features and Benefits

- Packing element configuration:

– Delivers increased reliability when removing the barrier if debris is trapped on top;

– Reduces the likelihood of swabbing in the well during retrieval.

- Proven tool design:

– Enables right-hand set and release;

– Reduces required torque when releasing the barrier.

- Sure-test feature:

– Can be tested from above and below production zone.

- Well integrity and pressure control:

– Enables mesaurement of trapped pressure below the well barrier;

– Maintains well control.

Achieve short-term isolation and ensure smooth retrieval operations

CAPSTONE Wireline-Retrievable Well Barrier Minimize NPT, provide reliable wellbore isolation, and ensure smooth retrieval operations

Temporary well isolation requires ft-for-purpose products that are reliable, in compliance with stringent regulations, and ultimately provide well control. V0-rated retrievable well barriers ensure gas-tight well control during temporary well isolation or suspension operations. Sometimes barrier retrieval can be difficult, leading to costly intervention, non-productive time (NPT), and potential loss of well. This can be caused by numerous issues including debris, release malfunction, and wellbore obstructions, which can result in a stuck barrier.

Baker Hughes has developed the CAPSTONE wireline retrievable well barrier to ensure the well has been isolated and the integrity of the wellbore is protected. The CAPSTONE well barrier features an advanced design for entry and retrieval operations, providing increased reliability and reduced NPT. Whether used for temporary suspension, well servicing, or even surface equipment repair, the barrier confirms total well control to enable safe operations and protect the environment.

The CAPSTONE wireline-retrievable well barrier offers field proven components, including an innovative equalizing valve with the use of a telescoping retrieving head to eliminate premature unsetting and improve reliability. The large I.D. bypass and large extrusion gap ensure reliability during the removal process. The well barrier is compatible with most industry-standard tools to enable flexibility and reduce operating costs. Its’ streamlined design allows for increased running speeds and maximum recovery, and also feature field-proven sealing technology to ensure total control.

The CAPSTONE barrier is part of the Baker Hughes STONE WALL V0-rated barrier portfolio—a comprehensive suite of tools that ensures gas-tight isolation throughout the well’s lifecycle.

CAPSTONE Wireline-Retrievable Well Barrie

Applications

- Temporary well isolation;

- Suspension;

- Well servicing;

- Surface equipment repair.

Features and Benefits

- Streamlined design:

– Improves running speeds;

– Enhances recovery.

- Compatible with industry standard tools:

– Provides flexibility;

– Reduces operational costs.

- Gas-tight sealing technology:

– Ensures total well control.

- Single-trip wireline equalization and retrieval :

– Reduces NPT;

– Maximizes production.

- Equalizing valve with the use of a telescoping retrieving head:

– Eliminates premature unsetting;

– Improves reliability.

- Large ID bypass and large extrusion gap:

– Enhances debris tolerance;

– Improves reliability in removal process.

- Tension or compression release:

– Increases reliability if debris buildup occurs.

石油圈

石油圈