ArrMaz, a U.S. based chemical company, has developed a new silica frac sand coating technology called SandTec, that could reduce respirable silica dust generated during hydraulic fracturing by up to 99%.

It is observed that the use of silica sand proppant per well in hydraulic fracturing has been steadily increasing. The exploration companies have discovered that there could be an increase in the well production if more sand is used for hydraulic fracturing. The sand helps prop open the formation, allowing hydrocarbons to flow more freely. But the transfer of sand proppant, generates respirable silica dust which, when inhaled, can impact worker health if not handled properly.

From past 3 years, Occupational Safety and Health Administration (OSHA) has been evaluating new proposed regulations for respirable crystalline silica which it estimates could affect almost 17,000 workers engaged in support activities for oil and gas operations. On March 23rd, 2016, OSHA announced a final rule on permissible exposure limit for respirable crystalline silica dust to be 50 micrograms per cubic meter of air.

The rule also requires that hydraulic fracturing operations use engineering controls as the first line of defense to protect workers against silica dust. The SandTec engineering control is more efficient than many other bulky mechanical systems which are difficult to mobilize onsite, require significant space, present handling risks, and are time consuming and expensive to set up and maintain.

Usually mechanical systems also do not provide protection at all transfer points. But SandTec applies a microscopic coating to frac sand proppant to control and minimize silica dust generation whenever and wherever proppant is transferred.

John Suldickas, Commercial Manager for Oil and Gas at ArrMaz said, “SandTec provides continuous protection from silica dust starting from the sand mine all the way to the hydraulic fracturing wellhead. It is easy to apply with no drying or curing required, and is biorenewable and biodegradeable addressing environmental concerns. Field results show it is effective in reducing silica dust to within OSHA’s new exposure limit. These characteristics make it the ideal solution for hydraulic fracturing operations to quickly and cost-effectively comply with OSHA’s final rule.”

“With pressing regulations that are expected to get even tighter, we recognized the need for a new and innovative solution for greater silica dust reduction. We worked with Schlumberger to create SandTec to significantly reduce silica dust during sand transfer,” said Dave Keselica, President and CEO of ArrMaz. “In addition to improved product performance, our customers are increasingly seeking sustainable solutions and we are proud to offer SandTec which is biodegradable and biorenewable.”

As an alternative to mechanical systems which present handling safety risks, take up valuable real estate at a hydraulic fracturing sites, are difficult to mobilize and remove and require regular maintenance, SandTec provides superior dust control performance, is easy to implement and provides protection from dust generation and proppant attrition at all sand transfer points along the entire supply chain. The benefit of SandTec is its ability to reduce silica dust whenever sand is transferred – from initial point of treatment to the well head. SandTec has been successfully tested at a number of hydraulic fracturing locations and has shown the ability to reduce silica dust levels below PEL action levels with no adverse effect on performance.

ArrMaz has been a leader in dust control coating technology for over 40 years, providing technology and application expertise to its clients around the globe. ArrMaz combined its coating technology and experience with Schlumberger’s knowledge of hydraulic fracturing to develop a unique product for reducing silica dust generation.

ArrMaz is proud to be a Sponsor of the 4th Annual Frac Sand Supply & Logistics Conference. Organized to assist sand suppliers, E & P companies, storage providers, equipment suppliers and other companies improve their supply chain operations, the conference will feature various topics of interest for the oil and gas industry.

Silica dust emissions from hydraulic fracturing are a continuing concern for the oil and gas industry.

Recognizing the need for a better solution to the problem, ArrMaz collaborated with industry experts, applied our more than 45 years of coating technology expertise, and adapted our proven coating application systems to develop an effective chemical technology solution for respirable crystalline silica dust control.

SandTec, our patent-pending, next-generation silica dust control proppant coating technology, is a proven solution, which, when applied to frac sand, results in significant reductions in respirable silica dust.

Our team of engineers and technical experts will customize a system to address your specific needs while ensuring a high-quality, silica dust-reducing frac sand for hydraulic fracturing operations.

Key Benefits

Up to 99% silica dust reduction built into the sand;

Significantly improved safety and site conditions;

Stable dust control that lasts through multiple frac sand transfers;

No setup, tear down or maintenance of mechanical dust control systems needed;

Frac fluid compatible with no negative impact on fracturing operations or well performance;

Smaller footprint since no valuable real estate is needed on the frac site;

Environmentally friendly.

ArrMaz Helps Oilfield Service Company Reduce Silica Dust Generation in Hydraulic Fracturing Operations

The Challenge

Our client, a prominent oilfield service company, has been using mechanical dust control systems during completion operations.

The company was seeking alternate solutions for maintaining dust within permissible exposure levels (PELs) set by OSHA and recommended by NIOSH. They also sought to reduce personnel- and equipment-related inefficiencies.

The new solution should control silica dust at all transfer points on each well site without negatively impacting fracturing operations or well performance.

The Solution

The ArrMaz Team provided a complete, portable silica dust control solution that integrated ArrMaz’s SandTec? silica dust control proppant coating technology and our proprietary coating application system to achieve optimal results;

SandTec works by applying a microscopic coating on sand proppant which controls dust and lowers fines generation by reducing abrasion whenever proppant is transferred;

SandTec coating was completely and evenly applied to frac sand supplied by a sand company for use in each well site’s completion operations. The sand company then transported the SandTec coated frac sand to all required locations using pneumatic trucks, and personal monitors were placed on job personnel to sample and measure respirable silica dust exposure as the sand was used in completion operations.

The Results

Monitors placed on multiple operators on each job site all showed frac sand coated with SandTec produced silica dust levels below current permissible exposure levels (PELs) set by OSHA and recommended by NIOSH.

Well Attributes

Well #1

Single well ops

12 total stages

3.1M lbs of treated sand

40/70 mesh size

Crosslink frac fluid

Personal airborne monitoring

Vacuum system shut down

Well #2

Single well ops

23 total stages

8.9M lbs of treated sand

950k lbs 100 mesh

1M lbs 20/40 mesh

6.9 million lbs 40/70

Slickwater frac fluid

Personal airborne monitoring

Vacuum system shut down

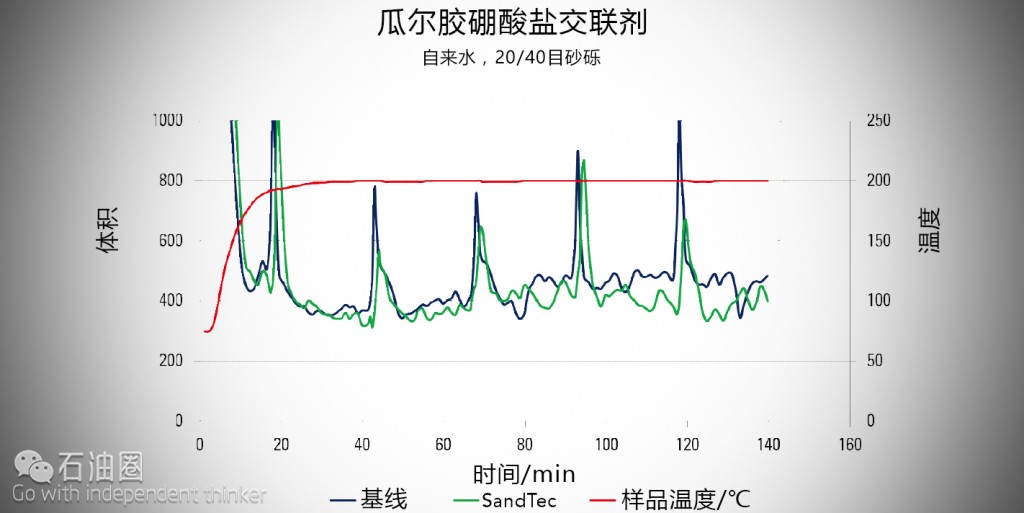

Trial Results for Silica Dust Generation

Key Benefits

Silica Dust Reduction Built into the Sand

Up to 99% reduction throughout supply chain

Significantly Improved Safety & Site Conditions

Greatly reduces silica dust

No setup or tear down of mechanical dust control equipment required

Enhanced Process Efficiency

Simplifies frac sand logistics

Provides protection at all locations and lasts through multiple transfers

Compatible with a wide variety of frac fluids

Does not slow fracturing operations or negatively affect well performance

Smaller Footprint

Does not occupy valuable real estate at the fracturing site

Environmentally Friendly

Made from naturally occurring biodegradeable / biorenewable, non-toxic, odorless

SandTec has been tested on a wide range of frac fluidsand has shown to be compatible.

石油圈

石油圈