A dilemma: Interventionless plug-and-perf

Interventionless frac plugs transformed plug-and-perf efficiency and enabled record-setting treatment depths by eliminating post-frac drillouts. But when interventionless downhole tools leave obstructions in the wellbore or restrict access, they can also complicate operations—now, and later.

The compromise: Increased efficiency … but with increased risk

The challenge: Mechanical strength and integrity—and total disintegration.

Combining seemingly incompatible properties into a single tool can be accomplished with advanced materials science and an unrelenting commitment to delivering what operators need.

The ideal solution: A frac plug that completely disappears downhole after fracturing.

Standard frac plugs use cast-iron slips and rings or ceramic buttons, coupled with a packer, to create a tight seal and hold plugs firmly in place. But some of these high-strength materials are nondissolvable, and materials that easily disintegrate in wellbore fluids are usually low in mechanical strength, and may disintegrate too fast.

The answer: Uniting competing physical properties

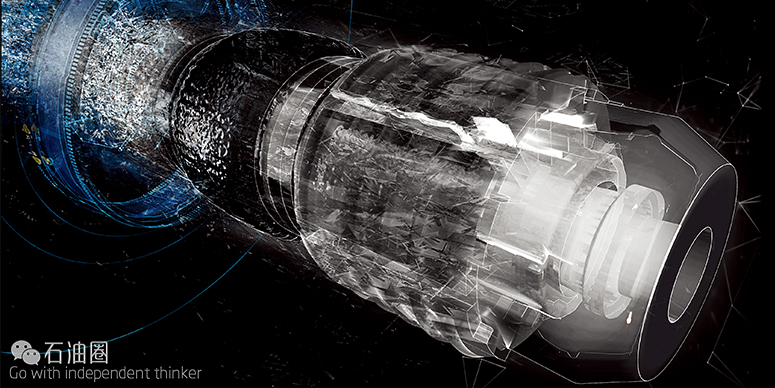

The SPECTRE™ frac plug is the industry’s first fully disintegrating plug, offering faster completion times, lower costs and risks, and an unobstructed fullbore production inside diameter (ID) for maximum flow area and simplified access.

Its innovative design leverages the high-strength, controlled electrolytic metallic (CEM) nanoconstructed material developed and patented by Baker Hughes. This designer material, which has been used in more than 80,000 successful stage treatments with IN-Tallic™ frac balls, disintegrates fully at predictable rates based on temperature and salinity.

The SPECTRE plug can reliably withstand the rigors of fracturing, and the entire plug— including the body, specially engineered IN-Tallic slip system, and packing element— fully disintegrates downhole in the presence of wellbore fluid.

The benefits: No post-frac intervention. No leftover debris. Unrestricted, fullbore access.

Eliminate coiled-tubing operations

When SPECTRE plugs are combined with the Alpha sleeve and IN-Tallic frac balls, coiled-tubing (CT) requirements are completely eliminated—during and after fracturing. This means faster completions and faster returns on investment.

During operations, the pressure-activated Alpha sleeve establishes initial access to the formation, rather than CT-deployed perforating guns. IN-Tallic disintegrating frac balls are seated on top of the SPECTRE plugs, diverting fracture treatments. And after all zones have been stimulated, production can be turned on, without intervention, saving an average of three days of completion time.

Avoid unplanned downtime

As with a traditional frac plug, the wireline-conveyed SPECTRE plug permits flexible stage placement and on-the-fly depth adjustments. During run-in, the risk of obstruction-related presets is significantly reduced by the plug’s unique, impact-resistant design, which distributes forces up through the toolstring, instead of the slip system.

At the desired depth, the plug’s packing element expands and seals against the casing. A specially designed IN-Tallic slip system, which balances frictional gripping forces with casing bite, secures the plug firmly in place.

Because the plug and ball are constructed of material that only reacts with produced fluids, the risk of premature degradation is effectively eliminated. During fracturing, the robust plug holds up to 10,000 psi, enabling reliable diversion of stimulation treatments into the formation.

After fracturing, the entire SPECTRE plug and IN-Tallic frac ball completely disintegrate, leaving behind a debris-free fullbore ID, permitting future wellbore access without concerns around ID restrictions or debris-related tool complications.

SPECTRE plugs also provide an ideal solution for depleted wells, where lifting plug debris to surface can be difficult and require costly gels and foams.

Reach more of the pay zone, in more locations

Drilling extended laterals in excess of 10,000 ft (3050 m) is a common practice in some basins. For most plug-and-perf completions, however, wellbores are generally confined to lengths that match the reach of CT units in the region. But because SPECTRE plug does not require post-frac drillout, it can be used in extended-reach applications. And more stages mean more pay zone access—and more production potential.

SPECTRE plugs are also ideal for remote locations where it may be difficult to mobilize CT intervention equipment. This means that development areas can be driven by opportunity and not by logistics.

Increase wellbore coverage, reduce well counts

Because the SPECTRE plug offers virtually unlimited treatment depths, more reservoir contact can be achieved per wellbore to reduce surface infrastructure and costs, while creating a more environmentally and community friendly operating footprint.

Simplify future access with a fullbore ID

Shale wells typically yield less than 10% of their recoverable reserves during short, initial production cycles. But recovery rates can often be increased through rejuvenation efforts, such as cleanouts, installation of artificial lift pumps, chemical programs, and/or restimulation. These operations, which often require an unobstructed fullbore ID, are made easier and less costly with the SPECTRE plug. The need for pre-intervention drillouts of wellbore profiles or removal plug debris is totally eliminated.

With the SPECTRE plug, you can realize all of the benefits of a truly disappearing frac plug: increased efficiency, reduced risk, fullbore access, and maximum flexibility. No compromises.

SPECTRE Frac Plug Increased Pay Zone Coverage by 30% and Eliminated Intervention in Deepest Stages

An operator working in the Woodford Shale in Oklahoma drilled an extended-reach well to access more pay zone and to increase production potential. The well had a total measured depth (TMD) of more than 22,200 ft (6772 m) with a 7,109 ft (2167 m) horizontal section. But the limited reach of coiled tubing (CT) presented an issue for the farthest depths of the well.

In traditional plug-and-perf completions, composite plugs have to be drilled out with CT-conveyed milling tools before production can flow. Applying sufficient weight on a milling bottomhole assembly to enable drillouts becomes unreliable in wells with extended horizontal wellbores. And composite plugs left in the well create a production barrier for the stages below, preventing recovery of hydrocarbons from that area.

To eliminate plug-related obstruction risks and the need for CT intervention in the farthest section of the well, Baker Hughes recommended installing SPECTRE™ disintegrating frac plugs in the lower stages. The plugs, which are constructed of high-strength controlled electrolytic metallic (CEM) material, can reliably withstand the rigors of fracturing, and then fully disintegrate downhole in

the presence of well fluids. No production-inhibiting plug debris, such as metal slips or ceramic buttons, are left in the wellbore.

The final completion design had a total of 45 stages and included a combination of SPECTRE plugs and composite plugs. Ten SPECTRE plugs were run first and successfully set in the lower section of the well. The deepest plug was set at 22,224 ft (6773 m) and the shallowest at 20,091 ft (6123 m). This section, which would have been too risky to complete using composite plugs, spanned more than 2,100 ft (640 m) of the 7,109 ft lateral.

As the lower stages were pumped, pressure signatures at the surface indicated successful diversion of treatments into each stage. SPECTRE plugs use IN-Tallic™ disintegrating frac balls to divert treatments, providing a completely disintegrating isolation solution. The remaining upper section of the wellbore was completed with 34 traditional composite plugs.

After fracturing operations were complete, the composite plugs were milled out and the well was put on production, exposing the SPECTRE plugs and IN-Tallic frac balls to reservoir fluids. After the disintegration process is complete, no plug or ball debris will be left behind, ensuring an unobstructed, fullbore production inside diameter (ID) without intervention. During the disintegration process, hydrocarbons are still able to pass through the SPECTRE plug’s enlarged flow-through ID.

The operator’s choice to use SPECTRE plugs in this well enabled 11 interventionless stages that were beyond the safe reach of CT in the long lateral. The plugs effectively increased pay zone coverage and production potential by more than 30%. And elimination of post-frac intervention in the lower stages provided greater efficiency, saving approximately 8 hours of completion time.

The operator was pleased with the performance of the SPECTRE plugs, and plans to use them in future wells.

石油圈

石油圈