大位移井具有能大范围地控制含油面积、提高油气采收率、降低油田开发成本等优点,具有显著的经济、社会效益,所以大位移井已成为目前开发边际油田的最有效手段之一。大位移井钻井液技术作为影响大位移井成败的关键因素,是大位移钻井技术的核心部分,其关键技术集中在降低摩阻和扭矩、保持井眼清洁、维持井壁稳定和随钻防漏堵漏等4个方面。石油圈原创www.oilsns.com

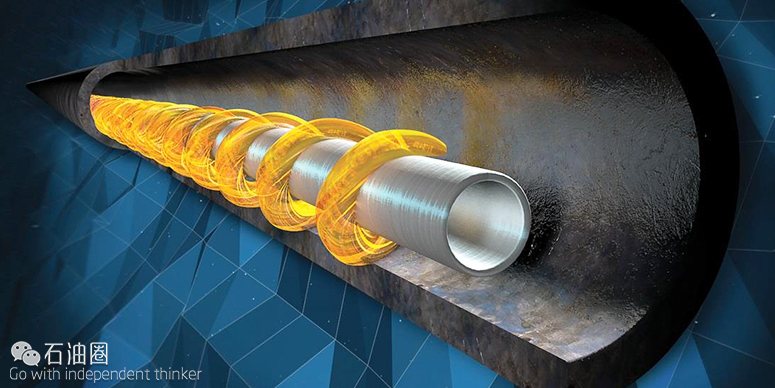

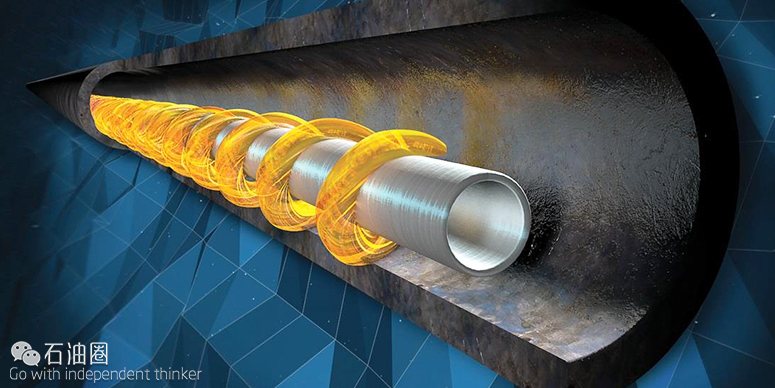

钻井过程中,存在钻柱与井壁间无任何介质隔开的干摩擦、钻柱与井壁边界膜产生的边界摩擦和由钻井液产生的流动摩擦3种摩擦方式。从减小摩阻的角度出发,要尽量避免干摩擦,降低边界摩擦和流动摩擦。实践证明,可以通过研选高效润滑剂来提高钻井液的润滑性能。

EasyReach润滑剂有利于连续油管在长井筒内的延伸,相较于其他类型润滑剂,使用较低的浓度便可提高效率并增强连续油管作业的操作准确性。它的问世为操作工程师提供了一种经济、高效、简便易行的降低机械摩阻的有效途径,帮助提高作业可预见性和改善单井经济效益。

EasyReach润滑剂的超强性能,成功助力贝克休斯OptiPort™多级压裂系统在美国的推广安装,摩阻系数的大幅降低使得环空压裂作业的影响深度能够更加接近于大位移水平井的趾端,避免发生连续油管摩阻锁定现象。石油圈原创www.oilsns.com

EasyReach润滑剂较其他常用润滑剂具有明显性能优势,测试结果表明它可使井下工具的摩擦系数在0.24的基础上降低40%~60%,横向穿深可增加120%,因此可成为大斜度长井段作业的一件利器。此外,EasyReach润滑剂已经广泛应用于贝克休斯OptiPort™水力压裂系统和OptiPacker™压缩式封隔器(用于横向位移超过3050米大斜度水平井的井下隔离)。

EasyReach润滑剂在大斜度长井段连续油管作业中的实际应用效果表明,该款利器可持续性降低钻具机械摩阻,降幅为40%~60%,是传统型润滑剂机械摩阻降幅的两倍,有力地验证了室内试验结论。新型润滑剂与EasyReach液动锤工具联合使用可大幅增加连续油管横向穿深能力。

在单井敞喷阶段,EasyReach润滑剂的应用,可显著降低多级压裂作业过程井底钻具组合上提拖曳力,从而可顺利快速地完成起钻操作并减少多级压裂作业间的操作时间。

应用范围

- 降低套管井作业井内钻具的机械摩阻;

- 连续油管系列作业;石油圈原创www.oilsns.com

- 大斜度井井筒干预包括:

- 环空压裂;

- 油管传输射孔;

- 磨铣作业;

- 测井作业;

- 酸化作业;石油圈原创www.oilsns.com

- 滑套开关作业。

特性与优点

基于先进的配方,EasyReach润滑剂摩阻系数降幅可达40~60%,水平位移增幅达120%。该润滑剂可在宽阈井下温度、压力与其他井下条件下应用,且性能显著优于传统润滑剂。

应用案例1

技术挑战

横向位移不少于1554.48米的大位移井,需要施加超过1000磅力的钻压才能实现封隔器坐封。

方案与结果

相较于传统型润滑剂,EasyReach润滑剂在连续油管作业中的应用可显著增加钻具横向位移。通过应用EasyReach润滑剂,无需液力锤或其他牵引工具,即可使井下钻具横向位移轻松突破3657.6米。石油圈原创www.oilsns.com

新型的EasyReach润滑剂显著降低了井下工具串的机械摩阻,助力连续油管延伸至井底,产生足够的钻压来坐封封隔器并完成作业任务,成功使井下钻具组合的摩擦系数降低了46%。

应用案例2

技术挑战

- 4-1/2”~7”无回接尾管完井管柱,对2in连续油管在井筒内的横向延伸形成了技术难题;

- 油管输送射孔深度需达到水平段趾端,数值达到3132.43米;

- 对于水平位移达到2164.08米的大斜度井,最小需要900磅力钻压才能实现可重复式封隔器的坐封。

方案与结果

- 将大斜度井横向延伸连续油管工具与EasyReach润滑剂联合应用;

- OptiPort多级压裂系统;石油圈原创www.oilsns.com

- 贝克休斯公司SHADOW系列压裂桥塞。

新型润滑剂应用后,可使大斜度井内摩擦系数降至0.13,即便井筒横向位移达到3132.43米,油管输送射孔管柱依然可延伸至水平段趾端,并在一次下钻期间完成10级压裂作业。当携砂液中的EasyReach润滑剂浓度仅为1.2%时,摩擦系数降幅达46%。

应用案例3

技术挑战

- 需要完成常规工具无法下放到位的大斜度井井筒的清垢、酸洗以及测井等作业;

- 连续油管工具尺寸最大可达2in,需要克服起重机载荷难题;

- 连续油管在相对较大的井筒内易发生螺旋屈曲,需要降低此类作业风险;

- 需要克服防砂筛管引起的摩阻增大影响。

方案与结果

- EasyReach连续油管大斜度井井筒干预服务;

-EasyReach金属面与金属面间的润滑剂;

-EasyReach液力锤工具。

- CIRCA建模与仿真软件;石油圈原创www.oilsns.com

- RotoJet高速旋转喷射工具。

通过使用EasyReach润滑剂,井下工具的摩擦系数降幅超过40%,成功助力井筒清垢、酸洗以及测井等作业的顺利开展;同时,整个作业过程节省了6小时的钻机时间,并节约了220加仑的润滑剂,有效预防了连续油管螺旋屈曲与井底钻具组合摩阻锁定等糟糕现象发生。该技术运用简单易行,运营商得以对附近单井成功地开展了类似井筒干预的作业。

水基钻井液的摩阻问题是制约其在大位移井中应用程度的关键问题,有效利用润滑剂可显著改善水基钻井液的润滑防卡性能,提高其作业能力。针对高温潜山地层的岩屑携带、裂缝性碳酸盐岩地层的防漏堵漏等复杂油气藏难题,大位移井水基钻井液的优化空间还很大,期待此项技术的进一步发展。

小编手中还握有EasyReach润滑剂和贝克休斯其他产品的更多资料哦,想获取?很简单:请将此文章分享至朋友圈,发送截图和邮箱地址至石油圈微信后台。小编会将资料打包奉上,发送至您的邮箱!

来自/Baker Hughes 译者/姚园 编辑/Leia

Baker Hughes EasyReach™ extended-reach coiled tubing lubricant is a mechanical friction reducer that helps coiled tubing gain access to long wellbores that were previously unreachable, even with conventional coiled tubing lubricants.

EasyReach lubricant performance was extensively tested using a one-of-a-kind linear friction testing methodology that was first to effectively simulate real downhole coiled tubing conditions and environments. Testing was conducted with multiple fluid combinations, lubricant concentrations, and material types at varying temperatures. This first-in- industry testing yielded significantly more predictable field results than could previously be achieved with typical lab testing.

Data gathered during the extensive testing of the EasyReach lubricant is now used with the Baker Hughes CIRCA™ pre-job and CIRCA RT on-the-job modeling software to effectively predict results in a wide range of coiled tubing environments. When included in the well design phase, EasyReach lubricant frees well designers to plan longer laterals that offer greater access to the payzone, increasing job efficiency and production potential.

EasyReach lubricant represents a step change over other available lubricants. It has been shown to drop the coefficient of friction (CoF) by between 40% and 60% from the standard value of 0.24, increasing lateral reach by as much as 120%. It is ideal for use in extended reach applications, and has been widely used with Baker Hughes OptiPort™ hydraulic fracturing systems and the OptiPacker™ compression set packer to isolate and treat laterals extending beyond 10,000 ft (3,050 m).

Field data from extended reach coiled tubing operations has shown that EasyReach lubricant consistently offers between 40% and 60% friction reduction in actual downhole conditions, effectively validating the lab results and doubling the friction reduction provided by conventional coiled tubing lubricants. The lubricant can be used in conjunction with the EasyReach fluid hammer tool to extend the reach of coiled tubing even farther.

EasyReach lubricant helps extend the reach of coiled tubing in long wellbores, improve efficiency, and increase certainty in coiled tubing operations, while using lower concentrations compared with other available lubricants. It offers a friction-reducing solution that is economical, efficient, and logistically easy to deploy, helping improve predictability and improve well economics.

EasyReach lubricant has been used extensively to enable Baker Hughes OptiPort™ multistage fracturing system installations in extended reach applications across the United States. Significant reductions in CoF have enabled annular fracturing treatments near the toe of extended lateral wells, helping avoid NPT due to coiled tubing friction lock.

The lubricant has also been used as part of the fracture treatment during the flush stage to reduce BHA drag while pulling up from stage to stage.

This allows for smooth and quick pull-out-of-hole operations and reduces the operating time between stages.

To learn more about how EasyReach lubricant can help you extend the reach of coiled tubing in long wellbores, contact your Baker Hughes representative today, or visit bakerhughes.com/easyreach.

Applications

- Cased hole operations requiring reduction in mechanical friction;

- Coiled tubing operations;

- Extended reach interventions including

—Annular fracturing;

—Tubing-conveyed perforating;

—Milling;

—Logging;

—Acidizing;

—Sleeve manipulation.

Features and Benefits

- Advanced formula

—Provides 40-60% reduction in CoF;

—Extends reach in laterals by up to 120%;

—Functions across a wide range of pressures, temperatures, and actual downhole conditions;

—Outperforms conventional lubricants.

- First in industry testing

—Accurately simulates downhole coiled tubing conditions;

—Field results validate lab testing.

- CIRCA modeling software

—Uses empirical data for job modeling;

—Delivers predictable field results.

Case History1

EasyReach Lubricant Nearly Halves the Friction in an Extended-Lateral Well, Increasing Reservoir Access.

Benefits

- Significantly increases the lateral reach of CT compared to current lubricants;

- Increased lateral reach of coiled tubing in a horizontal well without the use of fluid hammer or other extended reach tools;

- Combined with the EasyReach tool, it is anticipated that lateral lengths greater than 12,000 ft should be easily achievable.

Background and challenges

- Field trial of new lubricant to confirm lab results from proprietary linear- friction testing;

- Well was 5,100 ft lateral and required over 1,000 lbf available weight on bit to activate deployment packer;

- Fluid hammer or tractor tools traditionally used for extended reach were not applicable with the specific BHA, a deployment packer, being utilized.

Baker Hughes solution and results

- The EasyReach lubricant, a newly developed friction reducer, allowed the CT to reach TD with enough available weight to activate the deployment packer and complete the job;

- The EasyReach lubricant delivered a 46% reduction of friction in wellbore;

- Field results closely matched the lab test data completed using a new measuring process.

Case History2

EasyReach Lubricant Nearly Halves the Friction in an Extended-Lateral Well, Increasing Reservoir Access.

Results

- Achieved a 0.13 CoF in an extended lateral, enabling a TCP operation in the toe of a well with a lateral length of 10,277 ft;

- Reduced CoF by 46% with a lubricant concentration of only 1.2% in proppant- laden frac fluid;

- Enabled treatment of 10 stages that would have been otherwise unreachable with CT.

Challenges

- The 7-in. to 4½-in. liner completion with no tieback created lateral reach concerns for 2-in. CT;

- Toe needed to be perforated in the 10,277-ft lateral;

- Lateral length of 7,100 ft with a required minimum 900-lbf (1220-Nm) weight-on-bit to actuate the resettable packer.

Baker Hughes Solution

- EasyReach extended-reach CT service with lubricant

- OptiPort multistage fracturing system

- Baker Hughes SHADOW frac plugs

Case History3

EasyReach Lubricant Enabled Intervention in Horizontal, Sand-Screen-Completed Well.

Results

- Delivered scale cleanout, acid washing, and logging operations by reducing CoF by more than 40%;

- Saved 6 hours rig time and 220 gallons of lubricant by performing on-site force- matching;

- Prevented CT helical buckli g and BHA friction lock;

- Enabled operator to conduct a successful similar intervention on a second, nearby well.

Challenges

- Clean scale, acid wash, and log a purportedly unreachable lateral

- Accommodate crane limitations by intervening with maximum CT size of 2-in.

- Mitigate the CT tendency to helically buckle across the comparatively large wellbore

- Overcome increased friction caused by sand screens.

Baker Hughes solution

- EasyReach extended reach CT services;

—EasyReach metal-to-metal lubricant;

—EasyReach fluid hammer tool.

- CIRCA modeling and simulation software;

- RotoJet jetting tool.

未经允许,不得转载本站任何文章:

石油圈

石油圈