In the oilfield, primary technology drivers focus on safety, and of course, economic efficiency. Unfortunately, the deeper, harsher environments into which developments are moving often place these drivers in conflict. This is particularly true for subsurface safety valves where conventional solutions are being pushed to the limits of their capabilities.

To answer the challenges of ever-increasing water depths, a new freedom in placement and improved operating characteristics of the subsurface safety valve is needed. Previous deepwater safety valve solutions either required higher control system pressures to operate, often exceeding the pressure capabilities of the subsea umbilical, or required additional seals and/or the long-term retention of gas-charged chambers to provide for reduced operating pressures.

The DepthStar TRSV provides for a virtually unconstrained valve setting depth while operating at a consistently low control system pressure regardless of depth or well pressure, a critical factor in deepwater subsea wellhead applications.

Revolutionary step change improvements

The DepthStar tubing- retrievable safety valve (TRSV) is a subsurface safety valve that is run below the wellhead with the production tubing to provide reservoir integrity in an emergency shut down situation.

The DepthStar tubing-retrievable safety valve (TRSV) is a radical step change in design and, therefore, operational flexibility in the surface-controlled subsurface safety valve (SCSSV) arena. Its competitive advantages deliver the freedom to innovate and to meet oilfield challenges and opportunities.

Unlike prior designs, the DepthStar TRSV eliminates the need for a high-pressure SCSSV line and system. It employs a non-elastomeric, 100% metal-to-metal seal construction to meet the demands of deepwater, ultra-deepwater, and high-pressure/high-temperature (HPHT) environments. The valve contains a unique magnetic coupler that was specifically developed and rigorously tested for exactly such environments. This magnetic coupler reduces the operating pressure required since interaction between the hydraulic operating piston and the internal tubing-wellbore pressure is completely independent.

Completion design becomes radically simplified and more flexible with the DepthStar TRSV.

Here’s why:

•Requires lower operating pressure

•Helps increase environmental and personnel safety

•Extends system durability and reliability

•Enhances life of the well

•Reduces capital costs

•Reduces operational costs

Competitive advantages

•Deep and ultra-deepwater applications

•Completion design flexibility

•Optimum reliability and durability

•Reduced cost of overall operations without impacting operating capabilities

•Increased environmental and personnel safety

Features

•No moving sealing within tubing wellbore

•100% metal-to-metal seal within tubing wellbore

•Proven metal-to-metal, non-elastomeric hydraulic actuator isolated from wellbore

Benefits

•Low hydraulic operating pressure eliminates need for high-pressure system

•Operates independently of depth and wellbore pressure

•Unrestricted valve placement and depth limit for valve setting

•Increased valve reliability and extended valve life

•Full separation of wellbore conditions and hydraulic control system

A complete solution

How it works

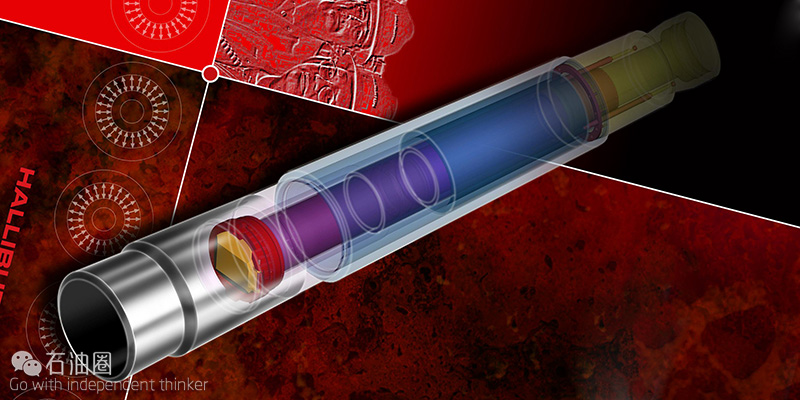

Magnetic coupler – Forces of attraction are equally paired and set from top to bottom in alternating segments. Magnetic coupler – Forces of attraction are balanced in a 360-degree equilibrium,eliminating friction and wear.

Unique magnetic coupler maximizes reliability

Through use of a unique magnetic coupler, the actuation piston and associated hydraulic operating system is separated from the wellbore environment. The incorporation of the magnetic coupler into the DepthStar TRSV brings several industry firsts in safety valve reliability:

1) There are no moving seals within the well bore where potentially harmful fluids and pressures can work against them

2) The only type of seals that are used in the wellbore are metal-to-metal seals, the most reliable in use

3) This is the first surface-controlled subsurface safety valve that can permanently isolate well fluids inside the production tubing and keep them from migrating into the TRSV control system.

Field-proven actuator

The DepthStar TRSV base design is the highly reliable, field-proven SP™ TRSV platform. It has been used in the harshest environments and yet attains a reliability performance of better than 98% over its multi-decade span. By designing the DepthStar concept on the successful SP platform, Halliburton rapidly carried the DepthStar TRSV from reliable to highly reliable.

Completion Flexibility

What does this technology mean to completion and subsea controls engineers? The DepthStar TRSV gives the completion engineer the flexibility to place the subsurface safety valve at a depth based on the requirements and goals of the completion and not based on the limitations of the safety valve. For the subsea controls engineer it could mean a paradigm shift in controls architecture. Today’s standard is to install a control system with an umbilical from the host platform to the subsea wellhead, which incorporates a high-pressure circuit (typically 10,000 psi) dedicated solely to operate the safety valve and a low pressure circuit to operate the other wellhead equipment. Operating at a consistently low control line pressure regardless of depth or well pressure, the DepthStar TRSV allows for controls architecture that requires only the low-pressure circuit in the umbilical and the high-pressure circuit eliminated.

Aside from the reliability gains that can be realized by operating at a lower pressure, there can be an economic advantage to installing the DepthStar TRSV as well. The cost savings from eliminating just the high-pressure control line from the subsea umbilical can be significant, often more than the cost of the DepthStar TRSV itself. When also considering that the topside equipment for the high-pressure circuit is no longer required, the reduction in controls equipment investment can be significant.

Where it Will Work

•Extended setting depth requirements

•Low control system operating pressure (subsea)

•Concerns of wellbore fluids (gas) communicating to the control system

•Ultimate reliability in operating with reduced operating pressures and no moving seals in wellbore

Award-Winning Technology

Winner of the Woelfel Best Mechanical Engineering

Achievement Award

•Winner of the OTC Spotlight on New Technology Award

•Winner of the Energy Institute Technology Award for Innovation

•Winner of the World Oil Best Completion Technology Award

石油圈

石油圈