Wild Well is proud to offer WellCONTAINED? Subsea Containment Solutions to the industry. Based on four decades of conventional and subsea well control experience, these unique containment systems provide a truly comprehensive solution to global deepwater well control incident prevention and response.

The WellCONTAINED system of services includes contingency planning and response from Source Control Emergency Response Planning (SCERP) through field deployment of the system, capping a subsea uncontrolled well.

WellCONTAINED components assist operators in prevention, preparation, response, and recovery operations related to deepwater well control events.

Components of WellCONTAINED Subsea Solutions:

SCERP

- Technical planning, drill/exercise, and response support;

- Complete global response equipment package;

- Relief well planning and well kill modeling;

- Firefighting and well control;

- Incident command structure and response training;

- Well control training.

Subsea Containment Equipment

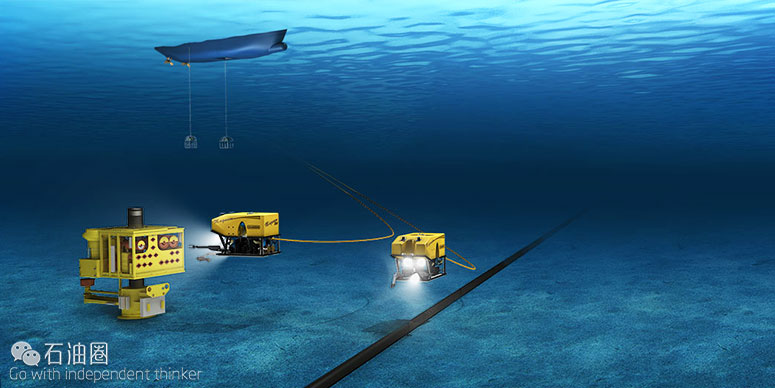

The WellCONTAINED subsea containment system of equipment is an integrated response system that is built and ready to respond to subsea well control incidents worldwide. The system includes a dedicated subsea capping stack that is specifically designed for capping operations. The complete capping stack is modular and allows for flexibility in the arrangement of the rams and drilling spool. The stack can be deployed on a wireline or drillpipe. Additional equipment in the WellCONTAINED package includes the 6 hydraulic shears for debris clearing, subsea dispersant injection equipment, and Wild Well Control’s source control management system of documents detailing well intervention procedures and operational support information.

The WellCONTAINED equipment package covers the critical aspects for well capping, containment, and collection designed for 10,000 ft water depth. The equipment package includes a set of various wellhead / capping stack hydraulic connectors that adapt to most subsea connectors. The capping stack is designed for both well containment (shut in the well), or for diversion and collection. The containment takes place using the three sets of rams. The collection is achieved by using the four way drilling spool with gooseneck connectors. The capping stack is maintained in transportable sizes for immediate deployment from Aberdeen, UK through vessels and air charter. A 50 GPM capacity subsea hydraulic power unit (SHPU) provides power and uses an environmentally friendly fluid to hydraulically function the capping stack and shears. The SHPU is capable of pumping hydrate inhibitors directly into the capping stack. For the debris clearing activities, the 2500 series shears have successfully cut drilling riser at a water depth of 5,000 ft. All subsea equipment shall have DNV certification.

WellCONTAINED Response Equipment

The WellCONTAINED system equipment package is adaptable for a multitude of response scenarios. The systems use field-proven equipment and are based on many years of subsea well control experience. Design criteria for the systems includes a depth rating to 10,000 fsw, 15,000 psi shut-in pressure, and dual mechanical barriers as well as the ability for ROV control of all functions. Additionally, the modular design facilitates rapid global deployment on readily available cargo aircraft. Both the Aberdeen and Singapore systems are 100% operational, as verified by third parties, and are staged in a state of deployable readiness

WellCONTAINED is an engineered response package designed to manage well control events from the initial response to the dispersant application, debris removal, and installation of the capping stack. With over 36 years of well intervention experience, WWC personnel are committed to helping operators with rig management and emergency response efforts. Operators are invited to join the WellCONTAINED Subsea Containment Solutions.

Access to the WellCONTAINED system equipment requires a special Equipment Access Agreement, in addition to an MSA, between the operator and Wild Well Control. Due to the heavy capital investment required, there are associated annual fees for the Equipment Access Agreement. The WellCONTAINED system equipment will be for the exclusive use of those operators that are participants in the Equipment Access Agreement.

Source Control Response Exercises

Wild Well has the unique ability to match exercise specialists with response-experienced, veteran well control engineers to form an unprecedented, source control and well control team. Our experience in all facets of emergency response, incident management, and operations allows for realistic exercise development and value-added evaluations and recommendations for improvement that are based on past experiences and best practices in the field.

In addition to our WellCONTAINED subsea well containment equipment, our team is well-versed in operator-owned and third-party global subsea well containment systems, e.g., Marine Well Containment Company, HWCG, Oil Spill Response Limited-Subsea Well Intervention System, et al.

WellCONTAINED participates in:

- Tabletop exercises;

- Drills (unannounced);

- Functional exercises;

- Full-scale exercises.

WellCONTAINED subject matter experts (SME) can fill any of the following roles at exercise:

- Players;

- Evaluators;

- Controllers;

- Facilitators;

- Simulators;

- Technical SME for design team;

- Source control coaches.

WellCONTAINED can assist in the following:

- Development of technical scenarios;

- Exercise design team participation;

- Master event scenario list (injects) development;

- Custom animations to articulate the scenario;

- Exercise objective development;

- Source control position-specific training prior to the exercise;

- Post-exercise evaluation/after-action report development;

- Technical simulation cell (SIMCELL) participation;

- Improvement planning;

- Development/review of multi-year training and exercise plans.

The System comprises four basic modules:

- Debris removal;

- Subsea dispersant application;

- Capping stack;

- Subsea hydraulic power unit.

Subsea dispersant application

The subsea dispersant application package includes all required hardware to facilitate the application of dispersants subsea from the client-provided coiled tubing unit through application wands or ROV hot stabs. Key components include the coiled tubing routing manifold, subsea distribution manifold and subsea hose deployment reel with more than 3,000 ft of various length 1-in. application and 1-in. routing hose. The system is rated to 4,500 psi and may also be used to convey hydrate inhibition and remediation chemicals as well as control line fluids.

Debris removal

The debris removal package contains two sizes of subsea shears that provide the cutting capability of tubular and structural members up to 46 inches in size. The shears can be used for activities like cutting bent or broken riser, shearing pipe or clearing an area to prepare for capping stack activities. In addition to the shears, ROV utility cutting tools, such as the Super Grinder, are part of the kit and would be used for light debris removal and site preparation for the capping stack installation.

Subsea hydraulic power unit

To provide localized hydraulic power to function the equipment that may be employed during the response operations, multiple options for subsea hydraulic power may be provided. Options include a dedicated subsea hydraulic power unit system as well as ROV-deployable hydraulic skids. This tooling may also be used to conduct secondary operation of the primary BOP.

Capping stack

The capping stack comprises 18 3/4-in. 15K Cameron Type TL ram assemblies and a drilling spool with four 4 1/16-in. outlets, which facilitates the installation chokes for soft shut‐in operations or gooseneck assemblies for extended flow back/well kill operations. The capping stack also features chemical injection (dispersant or hydrate mitigation/remediation) as well as internal pressure and temperature monitoring capability with acoustic transmission of readings to surface. The stack can be connected to a BOP, flex joint or on top of a wellhead. The capping stack is deployable on either drillpipe or wire, and deployment is aided by a rig or by crane/winch wire with quick changeout of the running tool interface.

About Wild Well

Oil and gas operators around the world rely on Wild Well for engineered solutions that safely prevent and resolve well control incidents. Wild Well has been involved in the successful management and capping of hundreds of wells in recent years across onshore, inland waters, offshore and deepwater locations.

石油圈

石油圈