Abstract: Conventional miscible- or near-miscible-gasflood simulation often overestimates oil recovery, mostly because it does not capture a series of physical effects tending to limit interphase compositional exchanges.The authors present a new engineering solution to this problem in the near miscible case. The principle is, while using a black-oil or an equation-of-state description, to dynamically decrease the K-value of heavy components and possibly increase the K-value of light components as the oil saturation reaches the desired residual limit.

Introduction

The novel approach covered in this paper relies on an in-house research reservoir simulator (IHRRS). The starting point of this work is the model activated through the VAPPARS keyword in Eclipse 100 (black-oil code) that is extended to compositional simulation. The benefits of the proposed method are demonstrated on a reservoir-condition tertiary gas-injection experiment, performed in laboratories, for which residual saturations are easily and successfully history matched, along with oil-phase and individual- component production rate.

Thermodynamic Equilibrium in IHRRS and Saturation- Dependent Tuning of the Equilibrium Constant (SDTEC)

IHRRS is a research reservoir simulator designed to treat a general number of phases where each phase can hold an arbitrary number of components. Equations important to the use of IHRRS are described in detail in the complete paper. Also, detailed discussions of the use of the SDTEC method in black-oil and com?positional simulation are presented in the complete paper.

Application to the Matching of a Near-Miscible Tertiary Gas-Injection Experiment

The Experiment. In the following, the SDTEC method is applied to history match a reservoir-condition tertiary gas- injection experiment performed on a reservoir carbonate core from a West Africa field. The main purpose of the experiment was to investigate potential three- phase relative permeability reduction on the gas phase during gas injection following secondary waterflood; history match is then needed to obtain a set of relative permeability and capillary pressure curves along with coefficients for the SDTEC model, to be used later in full-field simulations to predict the performance of a future gas-injection project better.

The core used in the experiment underwent computed-tomography (CT) scan imaging and miscible-tracer testing and was considered homogeneous because its longitudinal dispersivity was less than 0.2 cm. It was loaded in a coreholding cell, which was set horizontally on an X-ray displacement rig. Primary drainage was performed on the core 100% saturated with water to establish initial water saturation; core wettability was then restored by aging the core with live oil inside at reservoir conditions for 2 weeks.

The experiment was performed at reservoir conditions of 310 bar and 145°C (in the following, reservoir or experimental conditions will refer to these pressure and temperature conditions). Crude oil and its associated gas were collected from a separator and recombined to reach the composition of the reservoir fluid. Injected gas used in the experiment was synthesized to match the composition of the gas injected in the field for which the minimum miscibility pressure with reservoir oil was estimated at 394 bar, by use of an in-house pressure/ volume/temperature simulator.

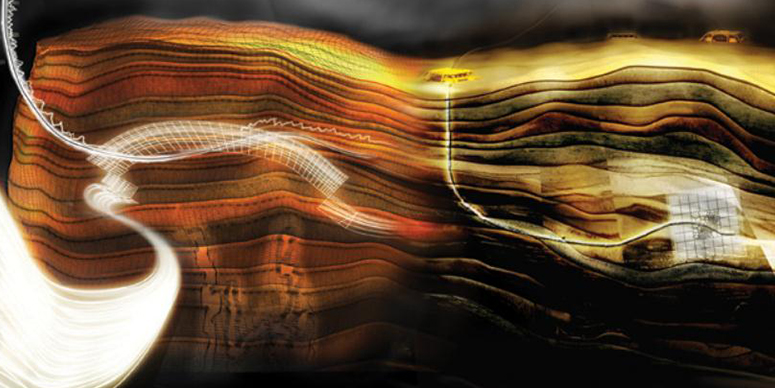

Fig. 1 shows the experimental setup, with the core-holding cell, the injection system, the production system, and the X-ray scanner. Produced fluids are collected in two high-pressure pumps, with the one connected to the core-holder outlet while the other is emptied. Pumps are emptied phase by phase to allow counting of the volumes at reservoir conditions and separating each phase when flashing volumes to laboratory conditions. This allows clear separation of flashed oil and condensate and rigorous measurement of oil formation volume factor, gas/oil ratio, vaporized oil, and dissolved gas. When a production pump is emptied, ef?fluent goes through a densimeter before being collected in a graduated burette. Volumes of liquids are then measured in the burette and undergo full com?positional analysis (i.e., C1—C30+). Gases go through a gas meter and a gas chromatograph for light-components analysis (i.e., C1-C7).

The X-ray scanner is composed of a dual-energy X-ray generator with a stable Nal detector set on a measurement rig with two displacement axes to allow 1D in-situ three-phase saturation measure-ments along several cross sections. Finally, a series of three differential-pressure sensors with different working ranges is set between the inlet and outlet of the core holder to measure differential pressure across the core with high resolution.

Injection rate was set to 2 cm3/h, corresponding to a front velocity of 0.3 m/d and a capillary number of less than 10-6, which describes flow behavior far from the wells. The experiment consisted of a continuous injection of brine followed by a continuous injection of gas. Each injection phase followed the same protocol: Start injection at 2 cm3/h and wait for stabilization in production and pressure drop (i.e., no further saturation changes); raise rate to 4 cm3/h until steady state is reached and then to 8 cm3/h to eliminate capillary end effects; and, finally, measure permeability of injected phase with Darcy’s law by decreasing the rate step by step.

History Matching. History matching of the experiment was performed with IHRRS on a 2D model with fine vertical gridding to resolve gravity segregation accurately and a horizontal block spacing matching the longitudinal dispersivity; gas fingering has not been observed during the simulations. An eight- component description was used in the simulation, using the Peng-Robinson equation of state. The matching methodology is as follows:

- Find a set of relative permeability and capillary pressure curves to fit oil, water, and gas production at reservoir conditions.

- Find residual oil to vaporization and coefficients to fit in-situ oil saturation, oil production at standard conditions, and individual-component production rate.

- Check whether reservoir-condition production and differential pressure are matched properly. If not, find a modified set of relative permeability and capillary pressure curves and go to Step 2.

This methodology is iterative but converges very quickly. Two iterations were sufficient to history match the experiment successfully.

All tested methods can provide a good match of the average in-situ oil saturation; however, only the SDTEC model and another investigated model (a-factors model) are able to match the evolution of the molar fractions of the different produced cuts properly. The SDTEC approach gives results very similar to those of the a-factors model, while needing to find a vector of eight coefficients only (the a-factors model requires a table of 64 coefficients). The task can be per-formed easily with an assisted-history- matching tool.

Applicability of the SDTEC Method to the Modeling of Condensate Recovery by Gas Cycling

When a gas/condensate reservoir is depleted below the dewpoint, a valuable liquid phase called retrograde condensate forms; a standard recovery practice consists of cycling dry gas so that, in addition to (partially or wholly) maintaining pressure, liquid components may be produced as vapor.

The problem is analogous to that of oil recovery by gas injection, except that quasicomplete recovery is often observed in coreflood experiments after sufficient pore volumes (PVs) have been injected. When the experiment duration is too short, it can usually still be matched to simulation by use of the thermodynamic- equilibrium assumption, provided that important physical parameters such as hydrodynamic dispersion are taken into account appropriately.

Because of macroscopic heterogeneities, however, it is not certain that complete thermodynamic equilibrium should be observed in grid blocks in field-scale simulations. For instance, gravity segregation of mobile condensate could cause the accumulation of localized clusters, which would later be bypassed by the cycling gas. The modeling of such phenomena is difficult and outside the scope of the present paper; the authors‘purpose in this work is to illustrate how the SDTEC method, developed and im-plemented in IHRRS and aimed at the modeling of residual oil saturation to gasflooding, can be used to enforce in?complete revaporization of condensate.

Conclusion

The purpose of this paper was to present a new method to enforce nonzero residual-oil saturation in near-miscible gas-flooding simulation on the basis of the addition of a saturation dependence to the equilibrium constants. The method applies to both black-oil and compositional formalism. Its essence is to reduce the vaporizability of the intermediate-to-heavy components as the oil saturation decreases toward the desired target, while leaving the equilibrium of light components unchanged (or possibly slightly modified). The threshold between light and intermediate-to- heavy components is based on a number of considerations. It is particularly important to ensure that the perturbed flash has a single solution, and that physical mechanisms relevant to the considered problem are not altered.

Introducing nonequilibrium effects by SDTEC has several advantages with respect to other published methods. First, the equilibrium modification is “local” (i.e., the thermodynamic constraints in each cell involve only properties of said cell), contrary to nonequilibrium models with rate-limited interphase mass transfer where spatial gradients are part of the constraints. Second, contrary to basic saturation-exclusion methods, it ensures oil degassing during primary depletion or final blowdown. Third, unlike the a-factors method, it requires a limited number of coefficients and the matching process can be automated easily; still, it is flexible enough with one tunable parameter per component.

Of course, it is an engineering solution in the sense that it does not derive from well-identified physical processes or from a rigorous upscaling of the kind. In the authors’ experience with near-miscible gas-injection coreflooding, it can be used easily for matching saturations and individual-component production vs. time.

The proposed SDTEC form also applies to the simulation of limited retrograde- condensate revaporization during gas cycling. It does indeed enable equilibrium dropout of condensate where the liquid saturation increases, while becoming active during the revaporization period. Phenomena potentially causing incomplete revaporization of condensate are typically above laboratory scale; hence, it is difficult to anticipate the appropriate parameters to use. The method could nevertheless be useful for sensitivity studies and for matching purposes, provided that appropriate monitoring of the reservoir behavior is available.

石油圈

石油圈