It’s a nightmare scenario no one wants… You run a PIG and it becomes stuck in the line. You now have an unsuccessful pigging campaign, a subsea pipeline blockage, and a missing PIG to deal with.

The cost of a shutdown due to a PIG stuck in a subsea pipeline can run into tens of millions in lost production, which is why it is absolutely critical to remedy the situation as quickly as possible. In this post we will examine the first step to remedying a blocked subsea pipeline due to a stuck PIG; that is locating the stuck PIG.

Step 1: Safety first

Whether you are running a pig as part of a cleaning campaign, an inline inspection, or a combination of factors, if it becomes stuck it can create an immediate production issue impacting on revenue AND potentially posing an EHS risk. So whilst remedial action must be carried out as efficiently as possible, it also needs to be safe. Whatever steps are chosen to find a stuck PIG in the subsea flowline, they must be selected based on a risk analysis with regard to environment, health, and safety.

Step 2: Do your background research for potential solutions to locating a stuck PIG in a subsea pipeline

In most cases, as part of the initial project, a stuck PIG would be identified on the risk register. The most prepared engineers will have considered not only the mitigation of that risk through preventative measures, but a plan for remediation if the risk came to pass. However, in the fast paced offshore E&P environment, taking account of every risk on the register, mitigating it ,and then creating a plan B for that scenario simply isn’t possible. So how do you pull together a solution quickly?

Resources such as the Pigging Products and Services Association (PPSA) can help. PPSA’s buyers guide or their technical enquiries service can be useful.

Offshore Magazine also have compiled a comprehensive comparison table of flow assurance solutions which is updated annually.

Tracerco offer a service for locating PIGs stuck in subsea pipelines, known as ExplorerTM, which you may want to consider as one of your options.

Benefits of Explorer™ for Flow Assurance:

Non-intrusively detect the location of deposition build up quickly without interrupting production

Real-time data on flow profiles

Monitor changes in deposition for an enhanced understanding of remediation efforts

Track the flow regime at specific reference points along the pipeline

Quickly identify flow assurance issues that may need further investigation

Quickly and non-intrusively locate any lost or stuck pigs

Step 3: Evaluate your options

Once you understand your options for locating the stuck PIG, and you are satisfied they can all be conducted to an acceptable EHS standard, you need to evaluate which is best for you. Here we have detailed a good checklist for evaluating which potential solution is right:

Access to the line

How much is required for the technology to work? Will I need to excavate? Things like this can add cost, and more importantly, timescales to your project.

Speed of deployment

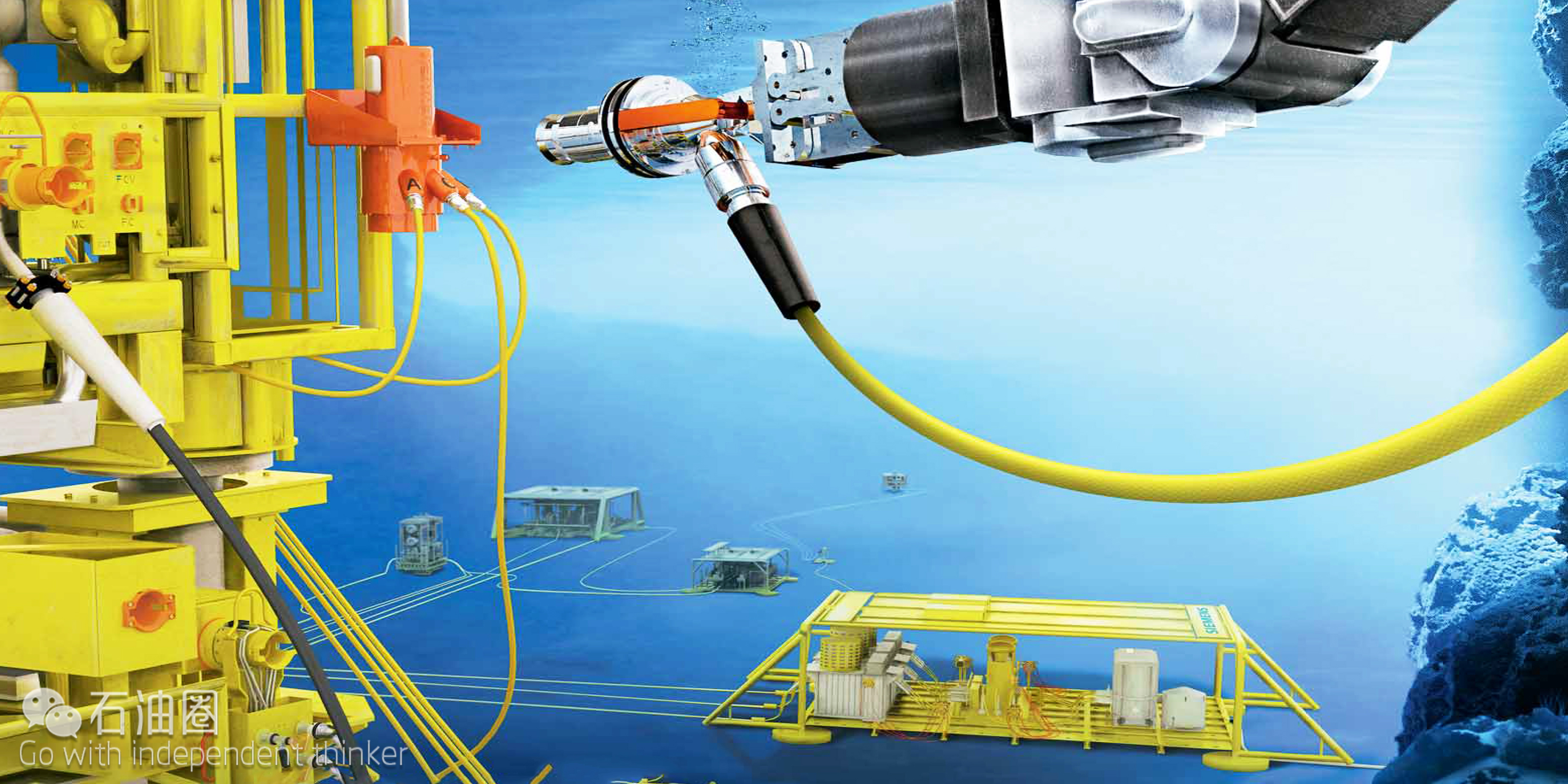

In many cases an ROV will be required to move the chosen technology along the pipeline for scanning and so the limiting factor would be the speed of the ROV. At best, using this type of technology you want something that can keep pace with an ROV without compromising the data collection.

Speed of results and data collection

Does your chosen technology perform the screening very quickly, but results need to be collated and analysed before you can have them? All this adds more to the time the line is shutdown. Once you locate the PIG you then need to remedy the line as the next step which could be even more complex and time consuming so you should aim for locating the PIG as your “quick win.” You need this phase to be as fast as possible, and that includes obtaining the results.

Cost of using the technology

This doesn’t include just the day rates of using the technology but other factors also need to be considered. Are any additional resources required (dive support vessels, ROVs etc.)? How long are they required? Does the line need to be prepared or modified in any way such as coating removal or excavation? All of these add to the cost of the project as a whole and should be looked at in conjunction with the advantages (in this case mostly to do with speed) of using that technology.

Step 4: Conduct your campaign to locate the stuck PIG

Whilst you need to locate the stuck PIG as quickly and efficiently as possible you should make sure you have completely understood your technology provider’s requirements and they are fully aware of the asset’s design, access, equipment available, your expectations, and problem. This will make for a smooth deployment and will help ensure a satisfactory conclusion to the project. Give your IRM contractor and technology provider as much information as you can about the line, and that will help them to deploy their technology for the best possible result.

Step 5: Learn from the incident and prepare for the future

The one single advantage of experiencing a stuck PIG in your line is that you are better prepared should the situation arise again in the future. Pigging subsea pipelines has become routine to the essential maintenance of a line, and so, whilst that scenario exists there is always a risk of a stuck PIG. Provided your location campaign was a success, and you were happy with the results, you now know who to contact in the event of a stuck PIG.

A more rigorous approach, that should form part of the initial risk mitigation strategy, is to ensure that your PIG’s are tagged with the best available tracking technology. This ensures that they can be monitored through the pipeline and then located even more quickly if they should get stuck. Tracerco’s pig tracking service uses radioisotopes, which is the most reliable and accurate method available.

CONCLUSION:

The key consideration when you need to locate a stuck PIG is how efficiently you can do this in order to minimise shutdown time. You need to be prepared to appoint suppliers quickly who are used to responding to emergency situations and can deploy efficiently and provide rapid real or near time data.

石油圈

石油圈